Feeling lost in a sea of interview questions? Landed that dream interview for Lens Blank Gauger but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lens Blank Gauger interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

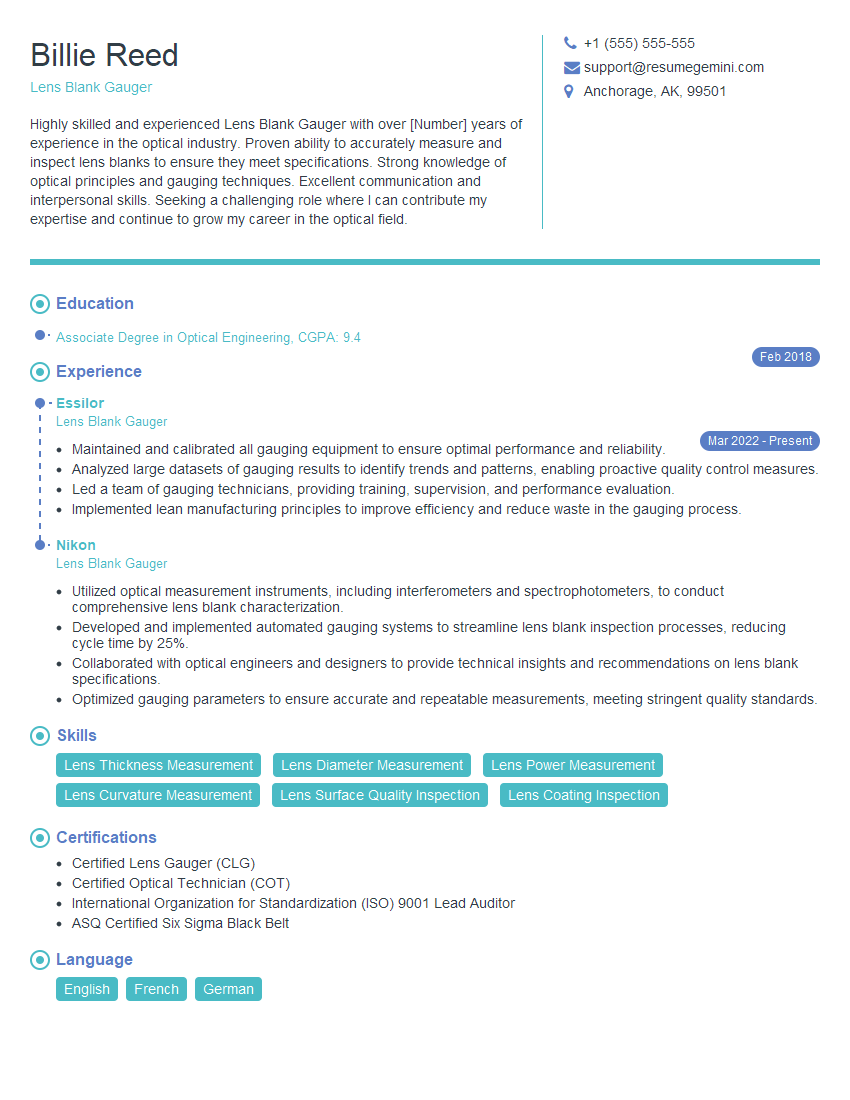

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lens Blank Gauger

1. What are the key factors that affect the accuracy of lens blank gauging?

The key factors that affect the accuracy of lens blank gauging include:

- Equipment calibration: Gauging equipment must be regularly calibrated to ensure accurate measurements.

- Operator training: Operators must be properly trained to use the equipment correctly and handle the lens blanks without damaging them.

- Sample preparation: The lens blanks must be properly prepared, cleaned, and free from defects.

- Environmental conditions: The ambient temperature, humidity, and vibration can affect the accuracy of the measurements and the lens blank dimensions.

2. Explain the importance of maintaining a clean and calibrated lens blank gauging machine.

Importance of maintaining a clean machine:

- Prevents contamination of the lens blanks.

- Avoids debris or particles from affecting the measurement accuracy.

- Ensures a consistent measurement environment.

Importance of calibration:

- Ensures accurate and reliable measurements.

- Compensates for wear and tear of the equipment over time.

- Maintains compliance with industry standards and regulations.

3. Describe the process of setting up and operating a lens blank gauging machine.

The process of setting up and operating a lens blank gauging machine typically involves the following steps:

- Mount the lens blank onto the gauging fixture.

- Align the lens blank in the measurement chamber.

- Select the appropriate measurement parameters and settings.

- Start the measuring cycle.

- Interpret the measurement data and record the results.

4. What are the different methods for measuring the thickness of a lens blank?

The different methods for measuring the thickness of a lens blank include:

- Contact methods: Using a micrometer or caliper to apply a force and measure the material’s thickness.

- Non-contact methods: Using optical techniques, such as laser triangulation or image analysis, to measure the thickness without physical contact.

5. How do you ensure the accuracy and repeatability of lens blank gauging measurements?

To ensure the accuracy and repeatability of lens blank gauging measurements, it is important to:

- Follow the manufacturer’s guidelines for operating the equipment.

- Use calibrated and traceable measurement standards.

- Regularly inspect and clean the measurement equipment.

- Evaluate the measurement process for sources of error and variability.

- Implement quality control procedures to monitor and maintain measurement accuracy.

6. Describe the challenges and solutions in measuring the thickness of a lens blank with complex geometry.

- Challenge: Measuring complex shapes with varying thickness.

- Solution: Use non-contact measurement techniques, such as image analysis or laser scanning, which can capture the shape and measure the thickness at multiple points.

- Challenge: Non-planar surfaces or curvature.

- Solution: Employ specialized gauging fixtures or adapt the measurement equipment to accommodate the complex shape.

7. What are the different types of gauging fixtures used for measuring lens blanks?

- Fixed fixtures: Hold the lens blank securely in a specific position.

- Adjustable fixtures: Allow for precise alignment and positioning of lens blanks with varying sizes.

- Customized fixtures: Designed specifically to accommodate the unique geometries of complex lens blanks.

8. Explain the role of software in lens blank gauging.

- Data acquisition and analysis: Software interfaces with the gauging equipment to collect and analyze measurement data.

- Parameter settings: Allows for the customization of measurement settings, such as the number of measurement points and the averaging method.

- Reporting and data management: Generates reports and stores measurement data for quality control purposes.

9. What are the best practices for handling and storing lens blanks to maintain their accuracy?

- Careful handling: Use clean gloves and appropriate tools to avoid scratches or damage.

- Proper storage: Store lens blanks in controlled temperature and humidity environments.

- Protective packaging: Use protective packaging materials to prevent scratches or contamination during transportation.

10. How do you stay updated with the latest advancements in lens blank gauging technology?

- Industry conferences and exhibitions: Attend industry events to learn about new technologies and best practices.

- Technical publications and research papers: Stay informed by reading technical articles and research publications.

- Collaboration with vendors: Partner with lens gauging equipment manufacturers and vendors to gain insights into the latest technology developments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lens Blank Gauger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lens Blank Gauger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lens Blank Gaugers are responsible for measuring and inspecting the dimensions of lens blanks. Their key responsibilities include:

1. Measuring and Inspecting Lens Blanks

Using specialized equipment, Lens Blank Gaugers measure and inspect the dimensions of lens blanks to ensure they meet specifications. They check for factors such as thickness, diameter, curvature, and surface quality.

2. Identifying and Reporting Defects

Lens Blank Gaugers identify and report any defects or deviations from specifications found during inspection. This helps prevent defective lenses from being produced.

3. Maintaining Equipment and Work Area

Lens Blank Gaugers maintain and calibrate the equipment used for measurement and inspection. They also keep their work area clean and organized to ensure accuracy and safety.

4. Following Quality Control Procedures

Lens Blank Gaugers follow established quality control procedures to ensure the accuracy and consistency of their measurements. This helps maintain high standards and product quality.

Interview Tips

To ace an interview for a Lens Blank Gauger position, candidates should consider the following preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Understand the specific responsibilities of the Lens Blank Gauger role and how it contributes to the company’s goals.

2. Prepare Specific Examples

Quantify your experiences whenever possible. When answering questions about your skills and experience, use specific examples to demonstrate your abilities. For instance, instead of saying “I have experience in quality control,” you could say, “At my previous job, I implemented a new inspection process that reduced defect rates by 15%.”

3. Highlight Your Attention to Detail

Lens Blank Gaugers require a high level of attention to detail. In your interview, emphasize your ability to focus on intricate details and ensure accuracy in your measurements and inspections.

4. Demonstrate Your Technical Skills

If applicable, show that you are proficient in using specific measuring and inspection equipment. Mention any certifications or training you have received in these areas.

5. Emphasize Your Communication Skills

Lens Blank Gaugers often work with other departments, such as production and quality assurance. Demonstrate your ability to communicate effectively and convey technical information clearly.

6. Ask Insightful Questions

Prepare thoughtful questions about the company, the role, and the industry. Asking insightful questions shows that you are engaged and genuinely interested in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lens Blank Gauger interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!