Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lens Block Gauger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

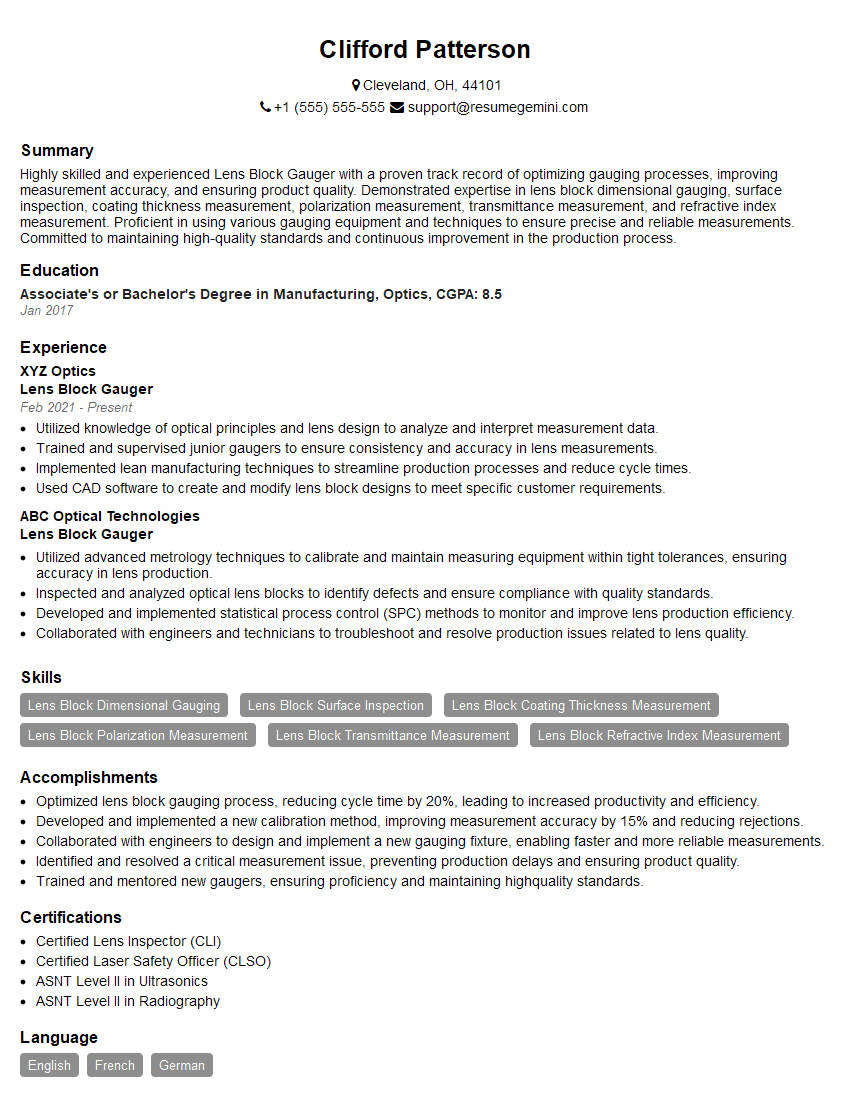

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lens Block Gauger

1. What are the key performance indicators (KPIs) you monitor to measure the effectiveness of your gauging process?

- Lens block acceptance rate

- Lens block rejection rate

- Gauging cycle time

- Gauging accuracy

- Gauging repeatability

2. How do you calibrate and maintain the lens block gauging equipment?

- Follow the manufacturer’s calibration and maintenance procedures

- Use calibrated reference artifacts

- Perform regular preventive maintenance

- Keep a log of all calibration and maintenance activities

ISO/IEC 17025:2017 Standards Compliance

- Calibrate and maintain gauging equipment in accordance with ISO/IEC 17025:2017 standards

- Use accredited calibration services

- Maintain traceability to national or international standards

3. What are the common defects you encounter during lens block gauging?

- Lens block thickness variation

- Lens block shape distortion

- Lens block surface defects

- Lens block edge chipping

- Lens block contamination

4. How do you troubleshoot and resolve lens block gauging problems?

- Identify the source of the problem

- Develop and implement corrective actions

- Verify the effectiveness of the corrective actions

- Document the troubleshooting and resolution process

5. What is the importance of statistical process control (SPC) in lens block gauging?

- SPC helps to identify and control variation in the gauging process

- SPC helps to prevent lens block defects

- SPC helps to improve lens block gauging accuracy and repeatability

6. What are the different types of lens block gauging technologies?

- Contact gauging

- Non-contact gauging

- Optical gauging

- Laser gauging

- Coordinate measuring machines (CMMs)

7. What are the advantages and disadvantages of different lens block gauging technologies?

- Contact gauging: Advantages include high accuracy and repeatability. Disadvantages include potential for lens block damage.

- Non-contact gauging: Advantages include non-destructive testing and high speed. Disadvantages include lower accuracy and repeatability compared to contact gauging.

- Optical gauging: Advantages include non-destructive testing and high speed. Disadvantages include lower accuracy and repeatability compared to contact gauging.

- Laser gauging: Advantages include non-destructive testing, high speed, and high accuracy. Disadvantages include higher cost compared to other gauging technologies.

- CMMs: Advantages include high accuracy and repeatability. Disadvantages include slower speed and higher cost compared to other gauging technologies.

8. What are the challenges of lens block gauging in high-volume manufacturing?

- Maintaining high accuracy and repeatability

- Ensuring fast cycle times

- Preventing lens block damage

- Automating the gauging process

9. What are the latest trends in lens block gauging technology?

- Increased use of non-contact and optical gauging technologies

- Development of new gauging algorithms and software

- Integration of gauging equipment with automation systems

- Use of artificial intelligence (AI) and machine learning (ML) to improve gauging accuracy and repeatability

10. How do you stay up-to-date on the latest advances in lens block gauging technology?

- Attend industry conferences and exhibitions

- Read technical journals and articles

- Network with other lens block gauging professionals

- Participate in training and development programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lens Block Gauger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lens Block Gauger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lens Block Gaugers are highly skilled professionals responsible for performing intricate gauging and inspection tasks in manufacturing settings. Their primary responsibilities revolve around ensuring the accuracy and precision of lens blocks, which are critical components in optical and precision instrument manufacturing.

1. Gauging and Inspection

The primary responsibility of Lens Block Gaugers is to perform meticulous gauging and inspection of lens blocks. This involves:

- Measuring and verifying dimensions, such as thickness, diameter, and flatness, against specified tolerances.

- Inspecting for defects, scratches, and surface irregularities using a variety of specialized instruments and techniques.

- Ensuring that lens blocks meet stringent quality standards and specifications.

2. Machine Setup and Calibration

Lens Block Gaugers are responsible for setting up and calibrating gauging and inspection equipment to ensure accuracy and reliability. This includes:

- Installing, aligning, and configuring gauging machines to specific requirements.

- Performing calibration checks and adjustments to maintain equipment precision.

- Troubleshooting and resolving any issues with equipment operation.

3. Data Analysis and Reporting

Lens Block Gaugers analyze and interpret gauging and inspection data to ensure quality control and compliance. This involves:

- Interpreting technical drawings and specifications to understand measurement requirements.

- Analyzing data to identify trends and potential quality issues.

- Preparing reports and documentation that summarize inspection results and findings.

4. Quality Assurance and Control

Lens Block Gaugers play a vital role in ensuring quality assurance and control within manufacturing processes. This includes:

- Identifying and mitigating potential defects and non-conformances.

- Providing feedback and recommendations to improve manufacturing processes.

- Ensuring compliance with industry standards and regulations.

Interview Preparation Tips

To ace an interview for a Lens Block Gauger position, candidates should prepare thoroughly and showcase their skills and knowledge. Here are some tips and hacks to help candidates succeed:

1. Research the Company and Position

Research the company’s history, products, and industry standing. Understand the specific role of a Lens Block Gauger within the organization and align your qualifications and experience accordingly.

2. Practice Your Gauging Techniques

Demonstrate your expertise by practicing gauging and inspection techniques beforehand. Familiarize yourself with industry-standard methods and ensure you can articulate your proficiency.

3. Highlight Your Attention to Detail

Lens Block Gaugers must possess exceptional attention to detail. Emphasize your ability to detect minute imperfections and ensure precision in your work. Provide specific examples from your experience or training.

4. Showcase Your Technical Expertise

Demonstrate your understanding of gauging equipment, calibration procedures, and data analysis techniques. Explain how you troubleshoot and resolve technical issues effectively.

5. Emphasize Quality Control

Highlight your commitment to quality assurance and control. Describe your experience in identifying and mitigating potential defects and ensuring compliance with industry standards.

6. Prepare for Common Interview Questions

Anticipate common interview questions and prepare concise answers that showcase your skills and experience. Be ready to discuss your motivations for applying, your strengths and weaknesses, and how you handle challenging situations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lens Block Gauger interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!