Feeling lost in a sea of interview questions? Landed that dream interview for Lens Cementer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lens Cementer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

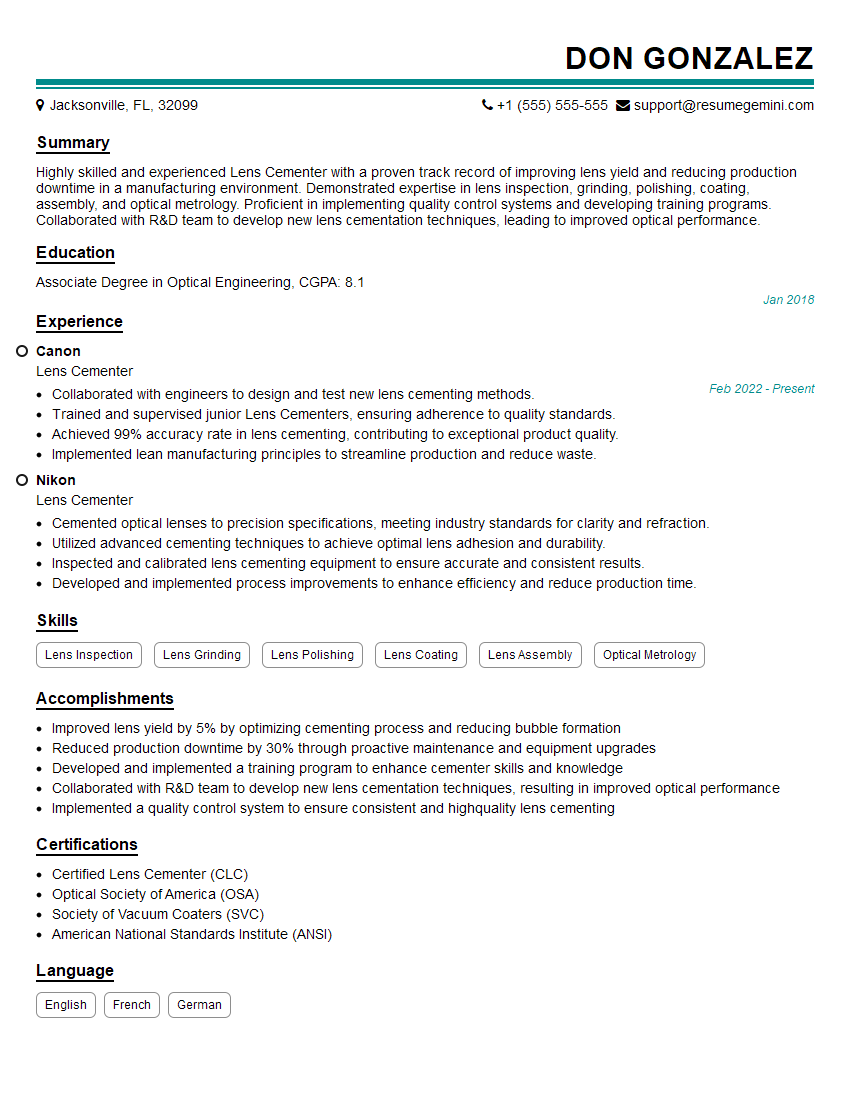

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lens Cementer

1. Describe the key steps involved in the lens cementing process?

- Preparing the lens surfaces: Cleaning and polishing the lens surfaces to ensure proper adhesion.

- Applying cement: Selecting and applying the appropriate cement based on the lens materials and optical requirements.

- Alignment and centering: Aligning the lenses accurately and ensuring proper centering to achieve optimal optical performance.

- Curing: Using heat, pressure, or UV light to cure the cement and create a strong bond between the lenses.

- Inspection and testing: Inspecting the cemented lenses for defects, clarity, and meeting optical specifications.

2. How do you determine the proper cement to use for different types of lenses?

- Material compatibility: Considering the refractive indices, thermal expansion coefficients, and chemical compatibility of the lens materials.

- Optical requirements: Selecting cement with properties that optimize light transmission, minimize distortion, and meet specific optical specifications.

- Processing conditions: Using cement that is suitable for the curing method (heat, pressure, UV light) and processing parameters.

- Environmental factors: Taking into account factors such as temperature, humidity, and potential exposure to chemicals.

subheading of the answer

- Manufacturer recommendations: Consulting with lens manufacturers and cement suppliers for specific recommendations based on the lens design.

- Testing and evaluation: Conducting tests to assess the performance and compatibility of different cement options with the intended lens materials.

3. What are the common defects that can occur during lens cementing and how do you prevent them?

- Bubbles or inclusions: Ensuring proper mixing and degassing of the cement, using vacuum techniques, and minimizing air exposure.

- Misalignment or decentration: Using precision alignment tools, checking lens centering, and employing fixturing to prevent movement during curing.

- Optical distortion: Selecting cement with low birefringence and controlling the curing process to prevent stress or strain in the cemented lenses.

- Cracks or delamination: Adhering to proper curing parameters, using compatible materials, and avoiding excessive forces or rapid temperature changes.

4. How do you handle and store different types of cement to maintain their integrity and performance?

- Temperature control: Storing cement at recommended temperatures to prevent degradation and maintain optimal properties.

- Humidity control: Storing cement in a dry environment to prevent moisture absorption and contamination.

- Light protection: Keeping cement away from direct sunlight or UV light to avoid premature curing or altering its optical properties.

- Proper packaging: Using airtight containers and sealing caps to prevent contamination and maintain cement freshness.

- First-in, first-out (FIFO) inventory system: Using older cement first to minimize the risk of extended storage and potential degradation.

5. What are the safety precautions you observe when working with lens cement?

- Protective gear: Wearing gloves, eye protection, and respiratory masks to avoid contact with skin, eyes, or inhalation of fumes.

- Proper ventilation: Ensuring adequate ventilation in the workspace to minimize exposure to cement vapors.

- Chemical handling: Following proper procedures for handling and disposing of cement and solvents, according to safety data sheets.

- Emergency preparedness: Knowing the location and proper use of eyewash stations and safety showers in case of accidental exposure.

6. How do you stay updated on the latest advancements in lens cementing techniques and materials?

- Industry conferences and exhibitions: Attending industry events to learn about new technologies, products, and best practices.

- Technical publications and journals: Reading technical papers, articles, and industry publications to stay informed about research and development.

- Online resources and forums: Participating in online communities, forums, and discussion groups to connect with professionals and exchange knowledge.

- Training and workshops: Enrolling in training programs and workshops to enhance skills and learn about emerging techniques.

7. Can you explain how the refractive index of the cement affects the optical performance of cemented lenses?

- Impact on light transmission: The refractive index of the cement determines the amount of light that is transmitted through the cemented lenses.

- Aberration correction: By carefully selecting the refractive index of the cement, it is possible to correct for optical aberrations in the lenses.

- Image quality: A mismatch in the refractive indices of the cement and lenses can lead to image distortion and reduced image quality.

8. Describe the process of testing the bond strength of cemented lenses and the different methods used.

- Shear testing: Applying force to the cemented lenses in a sideways direction to measure the resistance to separation.

- Tensile testing: Pulling the cemented lenses apart to measure the maximum force required to break the bond.

- Nondestructive testing: Using techniques like ultrasonic testing or optical microscopy to assess the bond strength without damaging the lenses.

9. How do you troubleshoot common problems that may arise during the lens cementing process?

- Bubbles or inclusions: Inspecting the cement and lenses for contamination, degassing the cement, and optimizing the mixing process.

- Misalignment: Checking the alignment tools and fixturing, ensuring proper lens preparation, and verifying curing parameters.

- Optical distortion: Analyzing the cement properties, curing conditions, and lens design to identify potential causes and implement corrective measures.

10. What are the key factors to consider when selecting a lens cement for a specific application?

- Lens materials and compatibility: Ensuring that the cement is compatible with the refractive indices and chemical properties of the lenses.

- Optical performance requirements: Selecting a cement that meets the desired light transmission, aberration correction, and image quality.

- Environmental conditions: Considering the operating temperature, humidity, and potential exposure to chemicals that the cemented lenses will encounter.

- Processing considerations: Choosing a cement that is suitable for the specific curing method and equipment used in the production process.

- Cost and availability: Balancing the performance requirements with the cost and availability of different cement options.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lens Cementer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lens Cementer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lens Cementer is responsible for cementing lenses together in order to create optical products such as eyeglasses, telescopes, and microscopes. This requires precise and delicate work, as well as a thorough understanding of the optical properties of glass and cement. Key responsibilities include:

1. Preparing lenses for cementing

This involves cleaning and preparing the surfaces of the lenses to be cemented, as well as applying a thin layer of cement to one or both surfaces.

2. Aligning and bonding lenses

The lenses are then carefully aligned and bonded together using a specialized machine or hand tools. The cement is cured under pressure and heat to create a strong and durable bond.

3. Inspecting and testing cemented lenses

Once the lenses are bonded, they are inspected for defects and tested to ensure that they meet the required optical specifications.

4. Maintaining equipment and workspace

Lens Cementers are also responsible for maintaining their equipment and workspace, as well as following safety protocols and procedures.

Interview Tips

To ace an interview for a Lens Cementer position, it is important to prepare thoroughly and highlight your skills and experience. Here are some tips:

1. Research the company and the position

This will help you understand the company’s culture and the specific requirements of the role. It will also show the interviewer that you are interested and invested in the opportunity.

2. Practice your answers to common interview questions

This will help you feel confident and prepared during the interview. Some common questions you may be asked include:

- Tell me about your experience with lens cementing.

- What are the most important qualities of a successful Lens Cementer?

- How do you handle working with precise and delicate materials?

- What are your strengths and weaknesses as a Lens Cementer?

- Why are you interested in this position?

3. Bring examples of your work

If possible, bring examples of your work to the interview. This could include photos or videos of your cemented lenses, or samples of your work if you have them. This will give the interviewer a better understanding of your skills and abilities.

4. Be prepared to talk about your safety experience

Lens Cementers work with hazardous materials and equipment, so it is important to be able to discuss your safety experience and knowledge. This could include your experience with handling and storing chemicals, or your training in safety protocols and procedures.

5. Be enthusiastic and positive

A positive and enthusiastic attitude can go a long way in an interview. Be sure to highlight your passion for lens cementing and your desire to succeed in the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lens Cementer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!