Are you gearing up for an interview for a Lens Finisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lens Finisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

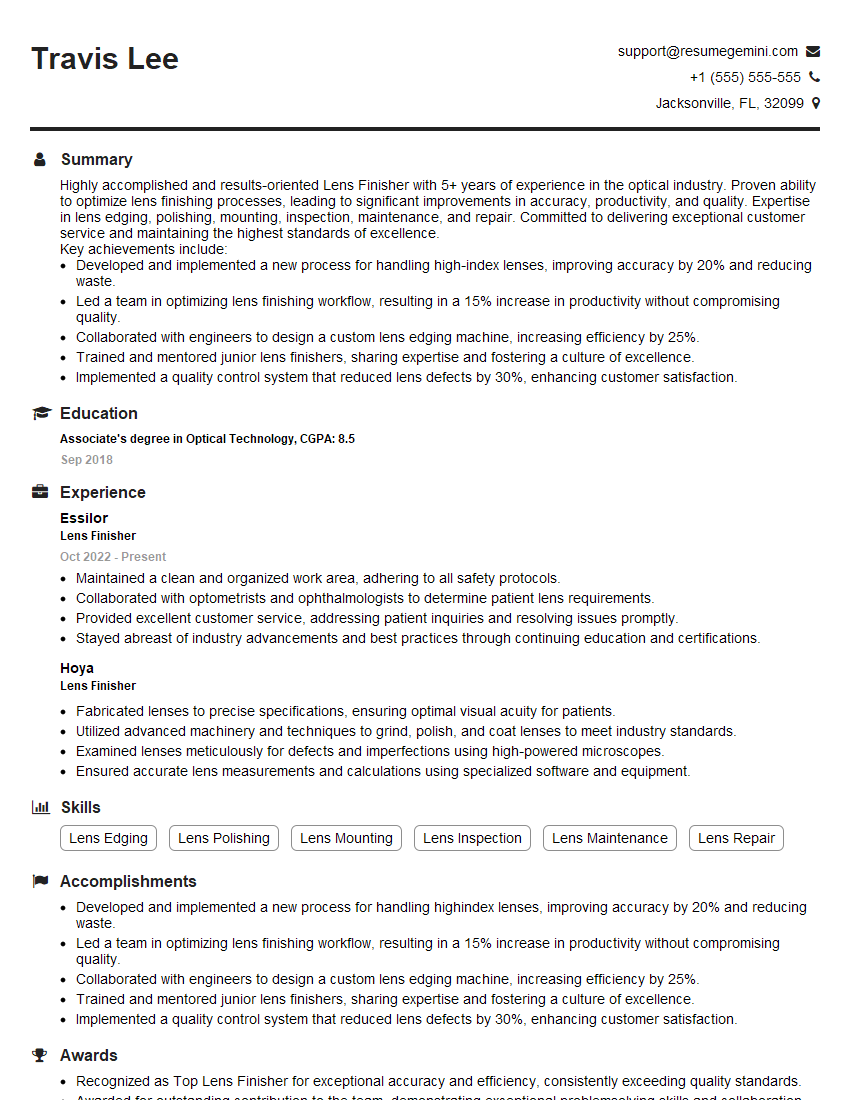

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lens Finisher

1. Describe the process of lens edging?

- Holding the lens in place with a vacuum chuck.

- Using a diamond-tipped wheel to grind the edge of the lens to the desired shape.

- Polishing the edge of the lens to remove any rough edges.

- Inspecting the lens to ensure that it meets the required specifications.

2. What are the different types of lens edging machines?

CNC edging machine

- Computer-controlled edging machine that can grind and polish lenses to precise specifications.

- Capable of handling a variety of lens materials and shapes.

Manual edging machine

- Manually operated edging machine that requires the operator to control the grinding and polishing process.

- Less precise than CNC edging machines, but can be used for smaller batches of lenses.

Combination edging machine

- Combination of CNC and manual edging machine.

- Can be used for both large and small batches of lenses.

3. What are the safety precautions that should be taken when operating a lens edging machine?

- Wearing safety glasses and a dust mask.

- Ensuring that the machine is properly grounded.

- Keeping the work area clean and free of debris.

- Never operating the machine while under the influence of alcohol or drugs.

4. What are the different types of lens materials that can be edged?

- Glass

- Plastic

- Polycarbonate

- Trivex

5. What are the different types of edges that can be created on a lens?

- Flat edge

- Beveled edge

- Rounded edge

- Custom edge

6. What are the quality standards that must be met when edging a lens?

- The edge must be smooth and free of any chips or scratches.

- The edge must be the correct shape and size.

- The edge must be polished to a high gloss.

- The lens must meet the required optical specifications.

7. What are the common problems that can occur when edging a lens?

- Chipping or scratching the lens

- Creating an edge that is too thick or thin

- Failing to polish the edge to a high gloss

- Producing a lens that does not meet the required optical specifications

8. What are the maintenance procedures that should be performed on a lens edging machine?

- Cleaning the machine regularly.

- Lubricating the moving parts.

- Inspecting the machine for any damage or wear.

- Calibrating the machine regularly.

9. What are the troubleshooting procedures that should be followed if a lens edging machine is not operating properly?

- Checking the power supply.

- Checking the vacuum chuck.

- Checking the diamond-tipped wheel.

- Checking the polishing wheel.

- Checking the software.

10. What are the future trends in lens edging technology?

- Increased use of CNC edging machines.

- Development of new lens materials that are easier to edge.

- Integration of lens edging machines with other optical equipment.

- Development of new edging techniques that improve the quality and efficiency of the process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lens Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lens Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lens Finishers are responsible for the final stages of lens production, ensuring that lenses meet the highest quality standards and specifications.

1. Finishing and Polishing Lenses

Using specialized equipment and techniques, Lens Finishers grind, polish, and shape lenses to achieve the desired curvature, thickness, and optical properties.

2. Quality Control and Inspection

They perform rigorous inspections and tests to ensure that lenses meet the manufacturer’s specifications for clarity, distortion, and overall optical performance.

3. Lens Assembly and Mounting

Lens Finishers assemble and mount lenses into frames, ensuring proper alignment and fit.

4. Customer Service and Support

They may interact with customers to provide technical support and address any concerns related to lens quality or performance.

Interview Tips

To ace an interview for a Lens Finisher position, candidates should prepare thoroughly by researching the company and the role, practicing their answers to common interview questions, and highlighting their relevant skills and experience.

1. Familiarize Yourself with the Company and Role

Research the company’s background, their values, and their specific product line. Show that you understand the company’s mission and the role’s responsibilities.

2. Practice Your Answers to Common Interview Questions

Prepare concise and well-structured answers to questions about your technical skills, experience in lens finishing, and quality control processes. Focus on highlighting your strengths and how they align with the job requirements.

3. Showcase Your Technical Proficiency

Emphasize your expertise in lens grinding, polishing, inspection, and assembly techniques. Provide concrete examples from your previous experiences that demonstrate your ability to produce high-quality lenses.

4. Highlight Your Quality Control Experience

Discuss your experience in implementing quality control standards, using inspection equipment, and ensuring the accuracy and consistency of lens products.

5. Demonstrate Your Attention to Detail

Stress your meticulous approach to lens finishing and your commitment to ensuring that every lens meets precise specifications and exceeds customer expectations.

Next Step:

Now that you’re armed with the knowledge of Lens Finisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lens Finisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini