Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lens Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

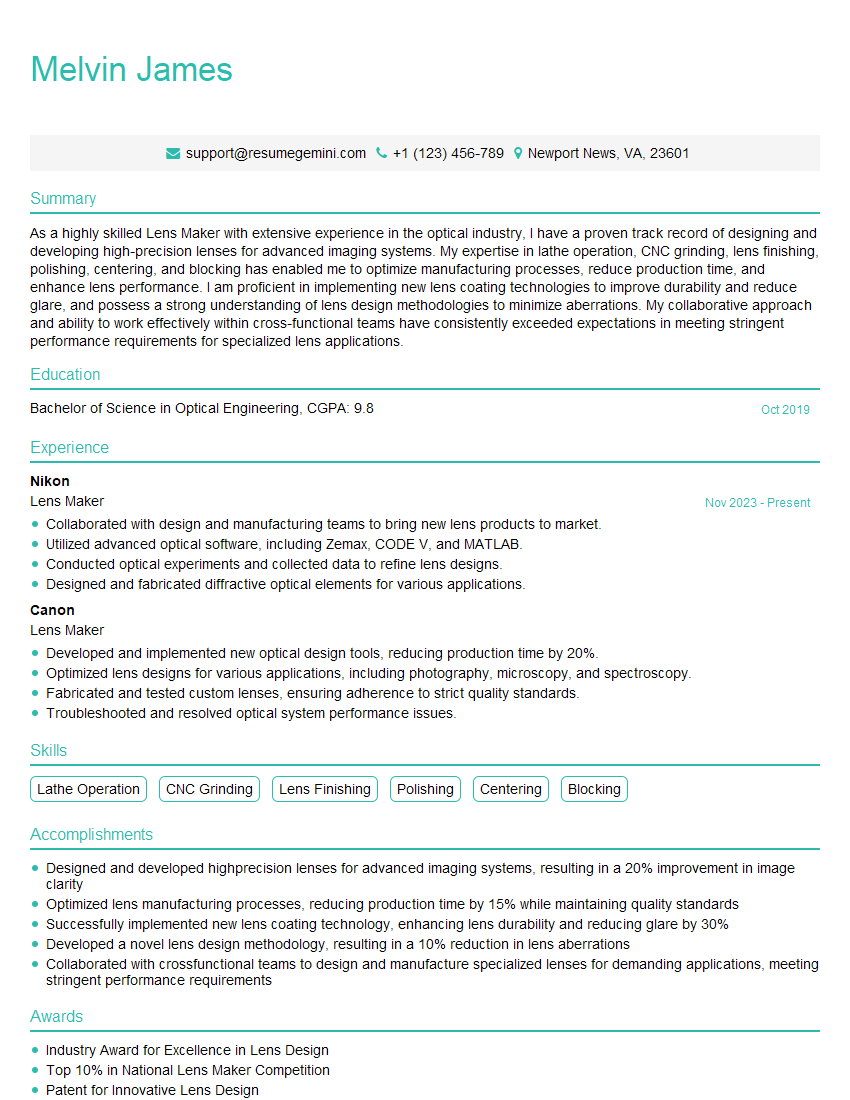

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lens Maker

1. What is the difference between a single vision lens and a progressive lens?

- Single vision lenses correct a single vision problem, such as nearsightedness or farsightedness, and provide clear vision at one specific distance.

- Progressive lenses, also known as multifocal lenses, correct multiple vision problems and provide clear vision at various distances without the need for separate reading glasses.

2. What are the factors to consider when selecting the appropriate lens material for a patient?

- Index of refraction

- Abbe value

- Specific gravity

- Impact resistance

- Scratch resistance

- Patient’s individual needs and preferences

:

- Index of refraction affects the thickness and weight of the lens.

- Abbe value indicates the lens’s clarity and image quality.

- Specific gravity determines the lens’s weight.

Subheading:

- Impact resistance is crucial for safety and durability.

- Scratch resistance ensures the lens’s longevity and optical clarity.

- The patient’s prescription, lifestyle, and budget should also be taken into account.

3. Describe the process of lens fabrication.

- Receiving the prescription from the eye care professional

- Selecting the appropriate lens material and design

- Generating the lens mold

- Casting the lens

- Annealing the lens to enhance its durability and stability

- Grinding and polishing the lens to achieve the prescribed shape and power

- Coating the lens with anti-reflective, scratch-resistant, or other desired treatments

- Final inspection and quality control

4. What are the different types of lens treatments available?

- Anti-reflective coating reduces reflections, improving clarity and vision comfort.

- Scratch-resistant coating protects the lens from scratches and wear.

- UV protection coating shields the eyes from harmful ultraviolet rays.

- Photochromic coating allows the lens to darken in sunlight and lighten indoors.

- Anti-fog coating prevents fogging on the lens surface.

5. What is the importance of lens quality control?

- Ensures the lens meets the patient’s prescription and provides clear vision.

- Guarantees the lens is free from defects and imperfections.

- Maintains the reputation and credibility of the lens manufacturer.

- Prevents potential liability issues.

- Improves patient satisfaction and enhances the overall optical experience.

6. Discuss the ethical considerations involved in lens making.

- Providing accurate and reliable vision correction to patients.

- Protecting patient privacy and confidentiality.

- Using high-quality materials and adhering to industry standards.

- Proper disposal of waste and hazardous materials.

- Maintaining a safe and healthy work environment for employees.

7. Describe the role of technology in modern lens making.

- Computer-aided design (CAD) software for lens design and optimization.

- Laser engraving for precise and repeatable lens shaping.

- Optical inspection systems for quality control and defect detection.

- Automated lens edging and coating processes for efficiency and accuracy.

- 3D printing for rapid prototyping and customized lens production.

8. What are the emerging trends in lens technology?

- Smart lenses with integrated electronics and sensors.

- Adaptive lenses that automatically adjust to changing vision needs.

- Nanotechnology-based lenses for enhanced optical properties.

- Biomimetic lenses inspired by nature’s optical systems.

- Virtual and augmented reality (VR/AR) lenses for immersive experiences.

9. Describe the challenges faced in lens making.

- Balancing optical performance with durability and comfort.

- Meeting the diverse vision needs and preferences of patients.

- Keeping up with technological advancements and market demand.

- Maintaining high quality standards while optimizing production efficiency.

- Navigating regulatory compliance and ethical issues.

10. What is your approach to continuing professional development in lens making?

- Attending conferences and workshops

- Reading industry publications and journals

- Participating in online courses and webinars

- Seeking mentorship from experienced lens makers

- Experimenting with new techniques and materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lens Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lens Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lens Makers are responsible for the production of lenses for optical instruments, such as eyeglasses, telescopes, and cameras. Their responsibilities include:

1. Grinding and Polishing Lenses

Lens Makers use specialized machinery to grind and polish lenses to the desired shape and size. This involves using a variety of tools and techniques to achieve the precise dimensions and optical properties required.

2. Coating Lenses

Lens Makers apply coatings to lenses to enhance their performance. Coatings can reduce reflection, increase scratch resistance, or change the color or tint of the lens.

3. Assembling Lenses into Frames

Once the lenses are produced, Lens Makers assemble them into frames. This involves carefully aligning the lenses and securing them in place to ensure proper fit and function.

4. Inspecting Lenses

Lens Makers thoroughly inspect lenses to ensure they meet quality standards. This involves using specialized equipment to check for defects, scratches, or other imperfections.

5. Maintaining Equipment

Lens Makers are responsible for maintaining and calibrating the equipment they use. This includes cleaning, lubricating, and adjusting machinery to ensure it is functioning properly.

Interview Tips

Preparing for a Lens Maker interview requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Company and the Industry

Familiarize yourself with the company’s history, products, and services. Research the optical industry to stay up-to-date on trends and advancements.

2. Highlight Your Technical Skills

Emphasize your expertise in grinding, polishing, coating, and inspecting lenses. Discuss your knowledge of optical properties and how you apply it in your work.

3. Showcase Your Attention to Detail

Lens Making requires meticulous attention to detail. Highlight examples where you consistently met or exceeded quality standards.

4. Prepare for Common Interview Questions

Practice answering common interview questions such as:

- Tell me about your experience in lens manufacturing.

- What are the different types of lenses you have worked with?

- Describe the process you use to grind and polish lenses.

- What is your favorite project you have worked on?

- Why are you interested in working for our company?

5. Bring a Portfolio

If possible, bring a portfolio of your work to the interview. This will provide the interviewer with tangible evidence of your skills and accomplishments.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lens Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!