Are you gearing up for a career in Lens Molding Equipment Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lens Molding Equipment Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

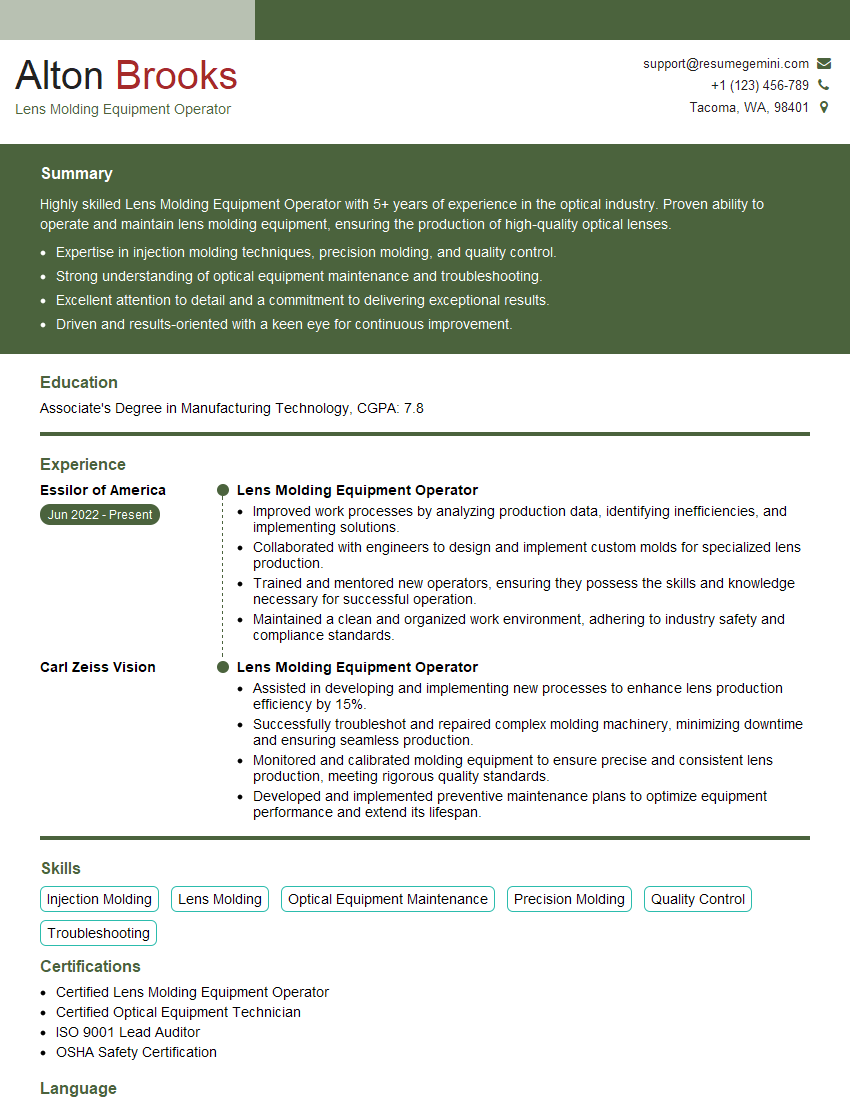

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lens Molding Equipment Operator

1. What are the different types of lens molding machines?

– Injection molding machines: These machines inject molten plastic into a mold to form lenses. – Compression molding machines: These machines press a preheated plastic sheet into a mold to form lenses. – Transfer molding machines: These machines transfer molten plastic from a pot to a mold to form lenses.

2. What are the key factors to consider when selecting a lens molding machine?

Factors to consider

- Lens size and shape

- Lens material

- Production volume

- Budget

3. What are the common problems that can occur during lens molding, and how do you troubleshoot them?

– Defects: Bubbles, scratches, streaks, and warpage. – Causes: Improper mold design, incorrect molding parameters, and contamination. – Troubleshooting: Inspect the mold for defects, adjust the molding parameters, and clean the machine.

4. What is the role of quality control in lens molding?

Quality control ensures that lenses meet the required specifications. It involves:

- Inspecting lenses for defects

- Measuring lens dimensions

- Testing lens optical properties

5. How do you maintain and calibrate a lens molding machine?

– Maintenance: Regularly clean the machine, lubricate moving parts, and replace worn components. – Calibration: Check the machine’s temperature, pressure, and other parameters regularly and adjust them as needed.

6. What safety precautions should be taken when operating a lens molding machine?

- Wear appropriate safety gear

- Keep the work area clean and free of hazards

- Follow the manufacturer’s operating instructions

7. What is the importance of training for lens molding equipment operators?

Training is essential for operators to:

- Learn safe operating procedures

- Understand the principles of lens molding

- Troubleshoot and solve problems

8. What are the latest advancements in lens molding technology?

- Increased automation

- Improved precision and accuracy

- Development of new lens materials

9. What is your experience with different types of lens molding machines?

I have experience with injection molding, compression molding, and transfer molding machines. I am familiar with their different features and capabilities, and I can select the right machine for the job.

10. Can you describe a time when you solved a complex problem with a lens molding machine?

Once, I was working on a machine that was producing lenses with scratches. I inspected the mold and found that it had a small burr. I removed the burr and the machine started producing lenses without scratches.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lens Molding Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lens Molding Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lens Molding Equipment Operator is responsible for operating and maintaining lens molding equipment used in the manufacturing of optical lenses. This individual plays a crucial role in ensuring the production of high-quality lenses that meet specifications and customer requirements.

1. Equipment Operation

The operator is responsible for setting up, operating, and monitoring lens molding equipment. This includes loading and unloading raw materials, adjusting process parameters, and monitoring the equipment’s performance to ensure optimal output.

- Load raw materials into equipment

- Set and adjust process parameters (e.g., temperature, pressure, cycle time)

- Monitor equipment performance and make adjustments as needed

- Identify and resolve any equipment malfunctions

2. Quality Control

The operator is responsible for inspecting and testing lenses to ensure they meet quality standards. This involves checking for defects, measuring dimensions, and verifying optical properties.

- Inspect lenses for defects (e.g., scratches, bubbles, inclusions)

- Measure lens dimensions (e.g., diameter, thickness, radius of curvature)

- Test optical properties (e.g., transmittance, reflectance, focal length)

- Maintain quality records and report any non-conforming lenses

3. Maintenance and Troubleshooting

The operator is responsible for maintaining and troubleshooting lens molding equipment. This includes performing routine maintenance, cleaning and calibrating the equipment, and identifying and resolving any technical issues.

- Perform routine maintenance (e.g., lubrication, cleaning, adjustments)

- Clean and calibrate equipment (e.g., sensors, optics, actuators)

- Troubleshoot and resolve equipment malfunctions

- Coordinate with maintenance personnel for major repairs or upgrades

4. Process Improvement

The operator may be involved in continuous improvement efforts to optimize the lens molding process. This can include identifying areas for improvement, implementing changes, and monitoring the results.

- Identify areas for process improvement

- Implement changes to improve efficiency or quality

- Monitor results and make further adjustments as needed

- Provide feedback on process improvements to supervisors or engineers

Interview Tips

Preparing for an interview for a Lens Molding Equipment Operator position requires a combination of technical knowledge, industry experience, and strong communication skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will demonstrate your interest and enthusiasm for the opportunity. Learn about the company’s products, services, and industry reputation. For the position, review the job description carefully and identify the key skills and responsibilities.

2. Highlight Relevant Experience and Skills

In your resume and during the interview, emphasize your relevant experience and skills. Focus on highlighting your experience in operating and maintaining lens molding equipment. Quantify your accomplishments whenever possible to demonstrate your impact. For example, instead of saying “I inspected lenses for defects,” you could say “I inspected over 10,000 lenses per day with a defect rate of less than 0.1%.”

3. Demonstrate Technical Knowledge

Be prepared to answer technical questions about lens molding equipment. This may include questions about the different types of equipment, the molding process, and quality control procedures. Review the principles of lens molding and be able to explain the key steps in the process. You should also be familiar with the industry standards and regulations related to lens manufacturing.

4. Emphasize Problem-Solving Abilities

Lens Molding Equipment Operators are often required to troubleshoot and resolve equipment malfunctions. In the interview, highlight your problem-solving abilities and provide examples of how you have successfully diagnosed and fixed equipment issues. Describe your approach to troubleshooting, including the steps you take to identify the root cause of the problem.

5. Practice Your Communication Skills

Effective communication is essential for Lens Molding Equipment Operators. Be prepared to clearly and concisely explain your experience, skills, and qualifications. Practice answering common interview questions and prepare thoughtful questions to ask the interviewer.

Next Step:

Now that you’re armed with the knowledge of Lens Molding Equipment Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lens Molding Equipment Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini