Are you gearing up for an interview for a Lens Shaper Grinder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lens Shaper Grinder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

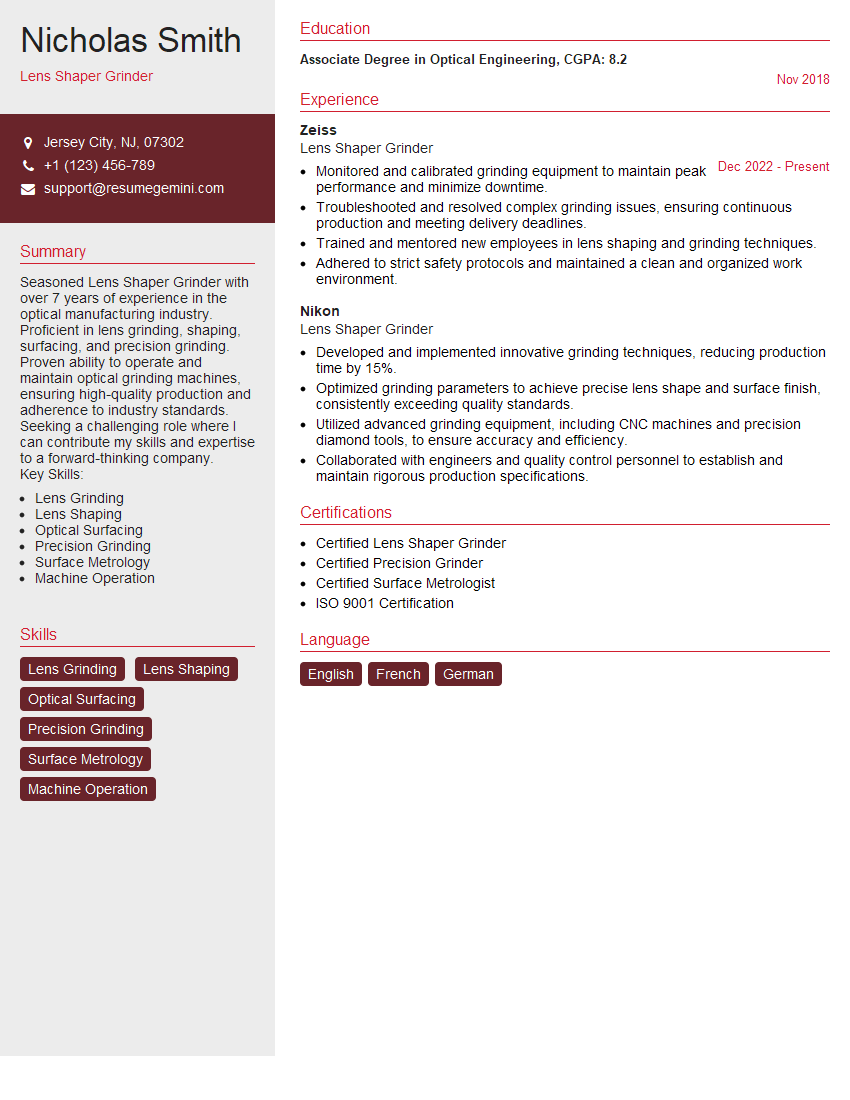

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lens Shaper Grinder

1. How to ensure the quality of the lens shaping and grinding process?

- Use high-precision grinding machines that are calibrated regularly to ensure accuracy.

- Utilize optical measuring instruments to verify the shape and dimensions of lenses.

- Implement a quality control system to monitor the process and identify any deviations.

- Conduct regular inspections and adjustments to maintain optimal performance.

- Train operators on proper techniques and safety procedures.

2. What types of lens shapes can you grind and what are the typical applications for each shape?

Plano-convex lenses

- Used in magnifying glasses, projectors, and laser pointers.

- Converge light rays to a focal point.

Plano-concave lenses

- Used in corrective eyewear, telescopes, and cameras.

- Diverge light rays away from a focal point.

Double-convex lenses

- Used in telescopes, microscopes, and eyeglasses.

- Converge light rays to a focal point on both sides.

Double-concave lenses

- Used in wide-angle lenses, telescopes, and eyeglasses.

- Diverge light rays away from focal points on both sides.

3. What are the common materials used in lens shaping and grinding?

- Glass (optical and borosilicate)

- Plastics (acrylic, polycarbonate, and CR-39)

- Crystals (sapphire and diamond)

- Metals (aluminum and titanium)

4. How do you select the appropriate grinding wheel for a specific lens material?

- Consider the hardness, grain size, and bonding of the grinding wheel.

- Choose a wheel that is slightly harder than the lens material.

- Use a finer grain size for smoother surfaces and a coarser grain size for faster material removal.

- Select a bonding that is appropriate for the grinding conditions (e.g., speed, pressure).

5. What are the safety precautions that must be followed when operating a lens shaping and grinding machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a lab coat.

- Ensure that the machine is properly grounded and maintained.

- Keep the work area clean and free of debris.

- Follow all operating instructions and procedures carefully.

- Never operate the machine under the influence of drugs or alcohol.

6. How do you troubleshoot common problems that may arise during lens shaping and grinding?

- Lens breakage: Check for proper machine calibration, grinding wheel selection, and lens mounting.

- Surface scratches: Use a finer grain grinding wheel, reduce grinding pressure, or adjust the grinding angle.

- Dimensional inaccuracies: Verify machine settings, use optical measuring instruments, and make necessary adjustments.

- Grinding wheel wear: Replace the grinding wheel as needed to maintain optimal performance.

- Machine vibration: Check for loose components, worn bearings, or unbalanced grinding wheels, and make necessary repairs.

7. What are the latest advancements in lens shaping and grinding technology?

- Computer Numerical Control (CNC) machines for precise and automated grinding.

- Ultraviolet (UV) laser grinding for high-precision and complex shapes.

- Aspherical lens grinding for reduced aberrations and improved optical performance.

- Nanotechnology for ultra-smooth surfaces and enhanced optical properties.

8. How do you stay updated with the latest industry trends and best practices in lens shaping and grinding?

- Attend industry conferences and exhibitions.

- Read technical journals and publications.

- Network with other professionals in the field.

- Participate in online forums and discussions.

9. How do you handle tight deadlines and ensure timely delivery of lens orders?

- Prioritize orders based on urgency.

- Optimize the grinding process for efficiency.

- Communicate with customers to manage expectations.

- Work overtime or adjust production schedules as needed.

- Maintain good relationships with suppliers to ensure timely material delivery.

10. How do you ensure the confidentiality and security of sensitive lens designs?

- Store lens designs securely in encrypted digital files.

- Limit access to design data only to authorized personnel.

- Use non-disclosure agreements with clients and partners.

- Implement physical security measures to protect equipment and data.

- Regularly monitor and update security protocols.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lens Shaper Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lens Shaper Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lens Shaper Grinder plays a crucial role in the optical industry, where precision and attention to detail are paramount. The key job responsibilities include:

1. Lens Shaping

Use specialized grinding equipment and techniques to shape and polish optical lenses to precise specifications, ensuring the desired optical properties.

- Operate precision grinding machines to remove excess glass and create the desired lens shape.

- Utilize polishing techniques to refine the lens surface and achieve the required smoothness and clarity.

2. Quality Control

Rigorously inspect lenses using optical measuring devices and quality control procedures to ensure they meet customer specifications and industry standards.

- Measure lens thickness, curvature, and other dimensions using precision instruments.

- Identify and correct any defects or imperfections in the lens surface or shape.

3. Equipment Maintenance

Maintain and calibrate grinding and polishing equipment to ensure optimal performance and accuracy.

- Monitor and adjust machine settings for precision grinding and polishing operations.

- Perform routine maintenance tasks to prevent breakdowns and ensure the equipment’s longevity.

4. Process Improvement

Continually seek ways to improve grinding and polishing processes by optimizing techniques and experimenting with new materials.

- Conduct research to identify advanced grinding and polishing methods.

- Collaborate with engineers and designers to develop innovative lens designs.

Interview Tips

To ace the interview for a Lens Shaper Grinder position, consider the following tips:

1. Emphasize Technical Skills

Highlight your proficiency in grinding and polishing techniques, as well as your knowledge of optical lens properties. Provide specific examples of your work and the results you achieved.

- Use industry-specific terminology to demonstrate your expertise.

- Quantify your accomplishments, such as the precision level you achieved or the number of lenses you produced.

2. Showcase Attention to Detail

Emphasize your meticulous nature and ability to consistently produce high-quality lenses. Describe your quality control procedures and how you ensure that each lens meets specifications.

- Provide examples of how you have identified and corrected lens defects.

- Discuss your understanding of the ISO or other relevant quality standards.

3. Highlight Equipment Knowledge

Demonstrate your familiarity with the types of grinding and polishing equipment used in the industry. Describe your experience in maintaining and calibrating machines.

- Mention any certifications or training you have received in operating or maintaining specific equipment.

- Explain how you troubleshoot common equipment issues and ensure its optimal performance.

4. Research Industry Trends

Show the interviewer that you are knowledgeable about the latest developments in lens manufacturing. Discuss any research or innovations that you are aware of in the field.

- Mention advancements in grinding and polishing technologies.

- Discuss new materials or coating techniques that improve lens performance.

Next Step:

Now that you’re armed with the knowledge of Lens Shaper Grinder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lens Shaper Grinder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini