Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Leverman position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

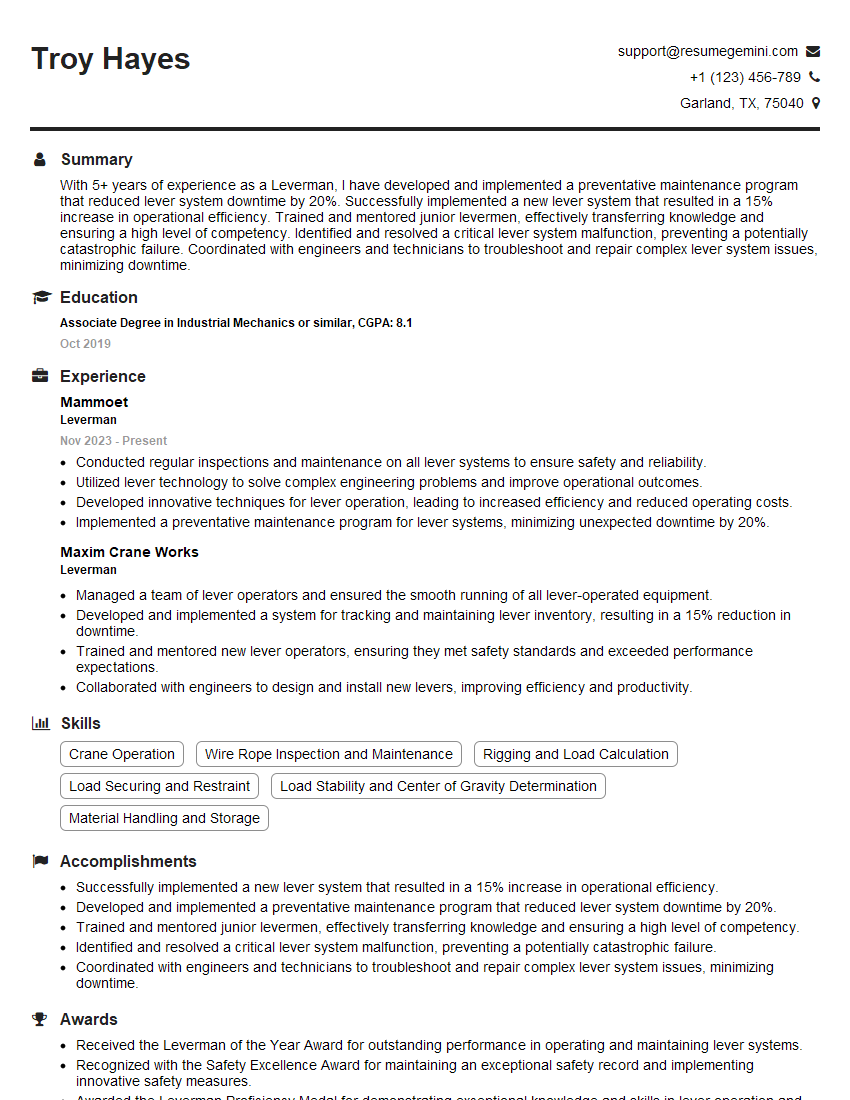

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Leverman

1. Can you describe the process of setting up a new lever?

In setting up a new lever, I would follow these steps:

- Determine the fulcrum point: This is the fixed point around which the lever will rotate.

- Calculate the distance from the fulcrum to the input force (effort arm): This distance determines the amount of force required to move the lever.

- Calculate the distance from the fulcrum to the output force (load arm): This distance determines the amount of force that the lever can exert.

- Choose a lever with the appropriate ratio of effort arm to load arm: This ratio will determine the mechanical advantage of the lever.

- Secure the lever in place: This can be done using bolts, screws, or other fasteners.

- Test the lever: Apply a force to the input force arm and observe the movement of the output force arm. Adjust the fulcrum point or the length of the lever arms as necessary to achieve the desired movement.

2. How would you calculate the mechanical advantage of a lever?

Mechanical Advantage Formula

To calculate the mechanical advantage of a lever, you can use the following formula:

Mechanical Advantage = Load Arm Length / Effort Arm Length

Example Calculation

For example, if the load arm length is 2 meters and the effort arm length is 1 meter, the mechanical advantage would be 2 (2 meters / 1 meter = 2).

Interpretation of Mechanical Advantage

The mechanical advantage of a lever tells you how much easier it is to move the load using the lever compared to moving it without the lever. In the example above, the mechanical advantage of 2 means that it is twice as easy to move the load using the lever than it would be to move it without the lever.

3. What are the three classes of levers, and can you provide an example of each?

- First Class Lever: The fulcrum is located between the effort and the load. Examples: Seesaw, teeter-totter, car jack

- Second Class Lever: The load is located between the fulcrum and the effort. Examples: Wheelbarrow, bottle opener, nutcracker

- Third Class Lever: The effort is located between the fulcrum and the load. Examples: Fishing pole, tongs, tweezers

4. How would you use a lever to lift a heavy object?

To use a lever to lift a heavy object, you would need to apply an effort force to the input force arm of the lever. This force would cause the lever to rotate around the fulcrum point, lifting the load on the output force arm.

The amount of force required to lift the object would depend on the mechanical advantage of the lever. A lever with a higher mechanical advantage would require less force to lift the object.

Here are the steps on how to use a lever to lift a heavy object:

- Position the lever so that the fulcrum is located between the object and the effort force.

- Apply a downward force to the input force arm of the lever.

- The lever will rotate around the fulcrum point, lifting the object on the output force arm.

- Continue applying force to the input force arm until the object is lifted to the desired height.

5. What are some of the applications of levers in everyday life?

- Construction: Levers are used in construction to lift heavy objects, such as beams and trusses.

- Transportation: Levers are used in transportation to move vehicles, such as cars and trucks.

- Sports: Levers are used in sports to improve performance, such as in baseball bats and golf clubs.

- Medicine: Levers are used in medicine to perform surgical procedures and to lift patients.

- Manufacturing: Levers are used in manufacturing to move and position materials and products.

6. How would you go about designing a lever to meet specific requirements?

To design a lever to meet specific requirements, I would follow these steps:

- Determine the input force (effort) that will be applied to the lever.

- Determine the output force (load) that the lever must exert.

- Calculate the mechanical advantage required to lift the load with the given input force.

- Choose a lever with the appropriate mechanical advantage.

- Determine the length of the input force arm and the output force arm based on the mechanical advantage.

- Select materials for the lever that are strong enough to withstand the forces that will be applied to it.

7. What are some of the factors that can affect the efficiency of a lever?

- Friction: Friction between the lever and the fulcrum can reduce the efficiency of the lever.

- Weight of the lever: The weight of the lever can also reduce its efficiency, especially if the lever is very heavy.

- Shape of the lever: The shape of the lever can affect its efficiency. A lever with a curved shape can be more efficient than a lever with a straight shape.

- Material of the lever: The material of the lever can also affect its efficiency. A lever made of a strong material, such as steel, will be more efficient than a lever made of a weak material, such as wood.

8. How would you troubleshoot a lever that is not working properly?

To troubleshoot a lever that is not working properly, I would follow these steps:

- Check for any visible damage to the lever, such as cracks or bends.

- Check the fulcrum point to make sure that it is not worn or damaged.

- Check the input force arm and the output force arm to make sure that they are not bent or damaged.

- Apply a force to the input force arm and observe the movement of the output force arm. If the output force arm does not move, or if it moves very slowly, then there may be a problem with the lever.

9. What are some of the safety precautions that should be taken when using a lever?

- Never use a lever to lift a load that is too heavy for it.

- Always make sure that the fulcrum point is stable and secure.

- Never place your hands or any other body parts under the lever.

- Always wear safety glasses when using a lever.

- Never use a lever that is damaged or defective.

10. How can levers be used to make work easier?

- Levers can be used to lift heavy objects with less effort.

- Levers can be used to move objects over long distances with less effort.

- Levers can be used to change the direction of a force.

- Levers can be used to amplify a force.

- Levers can be used to create a mechanical advantage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Leverman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Leverman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Levermen are responsible for operating levers that control the movement of machinery, equipment, or materials. They may also be responsible for visually inspecting the machinery or equipment to ensure that it is operating properly.

1. Operate Levers

Levermen are responsible for operating levers that control the movement of machinery, equipment, or materials. This may involve using levers to start, stop, or change the speed or direction of the machinery or equipment. Levermen may also use levers to control the flow of materials, such as liquids or gases.

- Operate levers to start, stop, or change the speed or direction of machinery or equipment.

- Control the flow of materials, such as liquids or gases.

2. Inspect Equipment

Levermen may be responsible for visually inspecting the machinery or equipment they operate to ensure that it is operating properly. This may involve looking for signs of wear or damage, and making sure that all parts are in good working order.

- Visually inspect machinery or equipment to ensure that it is operating properly.

- Look for signs of wear or damage.

- Make sure that all parts are in good working order.

3. Monitor Controls

Levermen may be responsible for monitoring controls to ensure that the machinery or equipment is operating within the desired parameters. This may involve using gauges or other instruments to check the temperature, pressure, or other conditions of the machinery or equipment.

- Monitor controls to ensure that the machinery or equipment is operating within the desired parameters.

- Use gauges or other instruments to check the temperature, pressure, or other conditions of the machinery or equipment.

4. Troubleshoot Problems

Levermen may be responsible for troubleshooting problems with the machinery or equipment they operate. This may involve identifying the source of the problem and taking steps to resolve it.

- Troubleshoot problems with the machinery or equipment they operate.

- Identify the source of the problem.

- Resolve the problem.

Interview Tips

To ace the interview for a Leverman position, it is important to be well-prepared. Here are a few tips to help you succeed:

1. Research the company and position

Take some time to research the company you are interviewing with and the specific Leverman position. This will help you understand the company’s culture and values, and the specific requirements of the job. You can find this information on the company’s website, social media pages, and other online sources.

- Visit the company’s website to learn about their culture and values.

- Read the job description carefully and identify the key requirements of the position.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself,” “Why do you want to work for this company?” and “What are your strengths and weaknesses?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and succinctly.

- Prepare answers to common interview questions such as “Tell me about yourself” and “Why do you want to work for this company?”

- Practice your answers out loud so that you can deliver them confidently.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Leverman. Be prepared to talk about your previous roles, your responsibilities, and your accomplishments. You can also mention any relevant skills or training that you have.

- Highlight your experience as a Leverman and your key responsibilities.

- Quantify your accomplishments using specific numbers and metrics.

- Be prepared to discuss any relevant skills or training that you have.

4. Be enthusiastic and ask questions

It is important to show the interviewer that you are enthusiastic about the position and the company. Be sure to ask questions about the company, the position, and the team. This will show the interviewer that you are interested in learning more about the opportunity and that you are serious about the role.

- Show your enthusiasm for the position and the company.

- Ask questions about the company, the position, and the team.

- This will show the interviewer that you are interested in learning more about the opportunity.

Next Step:

Now that you’re armed with the knowledge of Leverman interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Leverman positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini