Are you gearing up for a career in Levers-Lace Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Levers-Lace Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

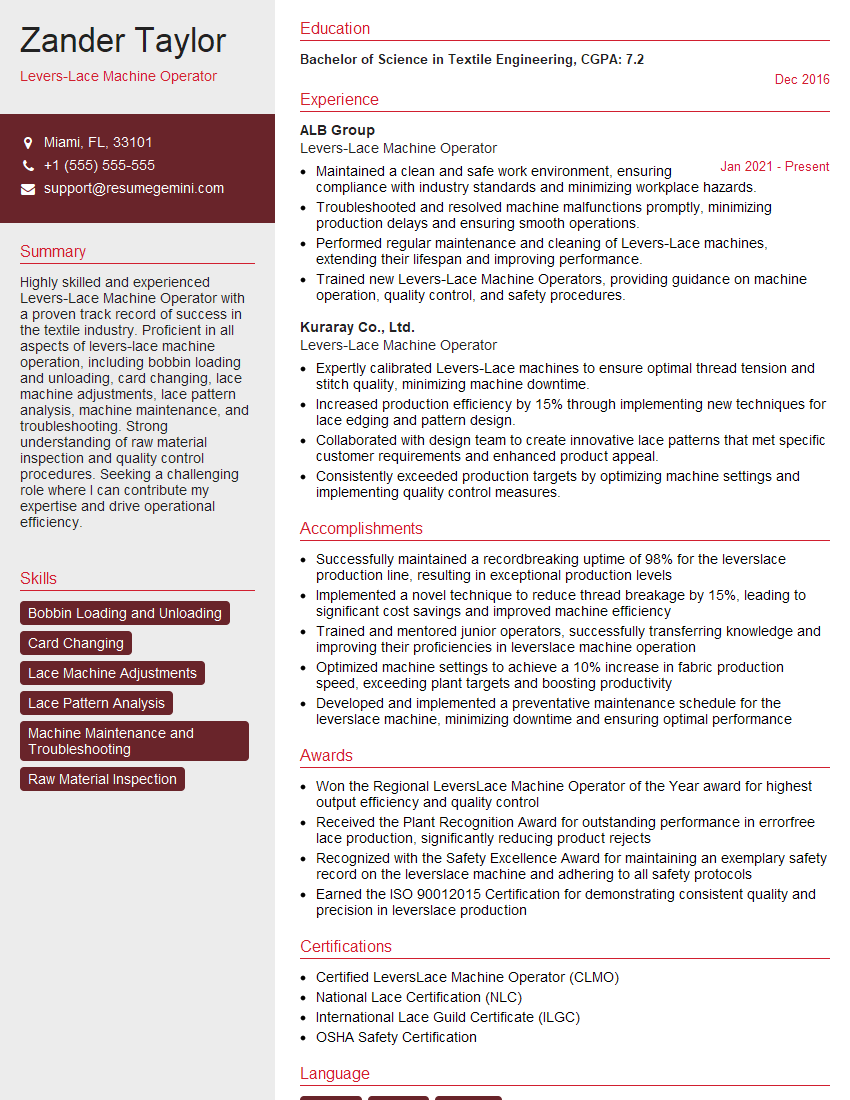

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Levers-Lace Machine Operator

1. What are the different types of levers-lace machines and what are their key features?

- Jacquard Machine

- Developed by Joseph Marie Jacquard in 1801

- Uses punched cards to control individual warp threads, creating complex patterns

- Capable of producing intricate laces with high precision

- Raschel Machine

- Invented in 1859 by Karl Raschel

- Produces warp-knitted fabrics with a high degree of elasticity

- Suitable for creating lace, mesh, and other elastic materials

- Leavers Machine

- Developed in 1813 by John Leavers

- Produces high-quality, narrow laces with delicate and precise patterns

- Utilizes a complex system of needles and carriages to create intricate designs

2. How do you troubleshoot common mechanical problems on levers-lace machines?

Problem: Machine is not starting

- Check power supply and connections

- Inspect wiring for any loose or damaged wires

- Reset circuit breakers or fuses if necessary

Problem: Broken needles

- Inspect needles for wear or damage

- Replace broken needles promptly

- Adjust needle tension as needed

Problem: Pattern distortion

- Check for incorrect threading or tension

- Inspect pattern cards for any errors or damage

- Calibrate machine settings to ensure proper yarn feed

3. What is the importance of yarn tension in levers-lace machines?

- Uniform tension ensures consistent stitch formation and lace quality

- Proper tension prevents yarn breakage, skipped stitches, and distorted patterns

- Too tight tension can cause yarn to snap or damage needles

- Too loose tension results in weak stitches and uneven lace

4. Describe the process of setting up a levers-lace machine for a new design.

- Prepare pattern cards for the desired design

- Thread the machine with the appropriate yarns

- Set machine parameters including stitch length, tension, and speed

- Calibrate the machine to ensure accurate pattern reproduction

- Run a sample piece to verify pattern and quality before production

5. What are the key factors to consider when maintaining levers-lace machines?

- Regular cleaning and lubrication to prevent wear and tear

- Needle inspection and replacement as needed to ensure stitch quality

- Voltage and power supply checks to maintain stable operation

- Preventive maintenance schedule to address potential issues before they occur

- Training for operators to ensure proper handling and maintenance

6. How do you handle production issues and minimize downtime on levers-lace machines?

- Promptly identify and diagnose any issues

- Communicate with maintenance if necessary for repairs

- Troubleshoot and resolve common problems as quickly as possible

- Maintain a spare parts inventory to reduce downtime

- Implement process improvements to enhance machine reliability and efficiency

7. Describe your experience in working with different types of yarns on levers-lace machines.

- Synthetic yarns (nylon, polyester): Durable, elastic, resistant to wear

- Natural fibers (silk, cotton): Luxurious, breathable, suitable for delicate laces

- Metallic yarns: Adds shimmer and glamour to designs

- Expedited processing time, reducing production time and increasing efficiency Improved product quality, resulting in fewer defects and higher customer satisfaction Increased production capacity, allowing for higher output and meeting increased demand

- Experience with color matching to ensure consistent and accurate lace production

8. How do you ensure the quality of lace produced on levers-lace machines?

- Monitor stitch formation for consistency and accuracy

- Inspect lace regularly for defects such as skipped stitches or irregular patterns

- Maintain proper maintenance schedules to prevent machine issues that could affect lace quality

- Use high-quality yarns that meet the specific requirements of the design

- Follow established quality control procedures to ensure consistent production standards

9. What safety precautions do you take when operating levers-lace machines?

- Wear appropriate safety gear (gloves, eye protection, earplugs)

- Follow all machine operating instructions and safety guidelines

- Never operate the machine without proper training

- Keep work area clean and free of tripping hazards

- Report any machine malfunctions or safety concerns promptly

10. How do you stay up-to-date with advancements in levers-lace machine technology?

- Attend industry conferences and workshops

- Read trade publications and online resources

- Consult with equipment manufacturers for updates and new developments

- Network with other levers-lace machine operators

- Explore online learning platforms for specialized courses or training

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Levers-Lace Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Levers-Lace Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Levers-Lace Machine Operators are responsible for overseeing the proper functioning of levers-lace machines, ensuring that they produce high-quality lace products according to specifications. Here are key job responsibilities:

1. Machine Operation

Operate levers-lace machines to produce lace according to specified patterns and designs.

- Set up machines and adjust settings to achieve optimal performance.

- Monitor machine operations and make necessary adjustments to maintain lace quality.

2. Lace Production

Produce lace of various types, including guipure, Chantilly, and Alençon lace.

- Inspect lace for defects and ensure it meets quality standards.

- Handle and store finished lace products properly to prevent damage.

3. Maintenance and Repair

Perform routine maintenance on machines, including cleaning, lubrication, and minor repairs.

- Identify and troubleshoot machine malfunctions, and perform repairs as needed.

- Assist with major repairs and overhauls as required.

4. Safety and Compliance

Follow established safety protocols and maintain a clean and organized work area.

- Wear appropriate safety gear and adhere to machine safety guidelines.

- Comply with industry regulations and quality standards pertaining to lace production.

Interview Tips

Preparing thoroughly for an interview can increase your chances of success. Here are some tips for acing the interview for a Levers-Lace Machine Operator position:

1. Research the Company and Role

Research the company’s history, products, and culture to demonstrate your interest and understanding of the organization. Familiarize yourself with the key job responsibilities and identify how your skills and experience align with them.

2. Practice Your Responses

Prepare for common interview questions by practicing your answers. Consider questions related to your experience with levers-lace machines, lace production techniques, and troubleshooting skills. Provide specific examples to support your responses.

3. Highlight Your Skills and Experience

Emphasize your technical skills related to levers-lace machine operation, lace production, and maintenance. Quantify your accomplishments whenever possible to demonstrate the impact of your work. Showcase your ability to produce high-quality lace and meet production targets.

4. Showcase Your Problem-Solving Abilities

Share examples of how you have identified and resolved machine malfunctions in the past. Discuss your approach to problem-solving and how you ensure that machines are operating efficiently.

5. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the lace industry and your desire to contribute to the company’s success. Maintain a professional demeanor throughout the interview and ask thoughtful questions to show your engagement and interest in the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Levers-Lace Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!