Are you gearing up for an interview for a Lift-Slab Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lift-Slab Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

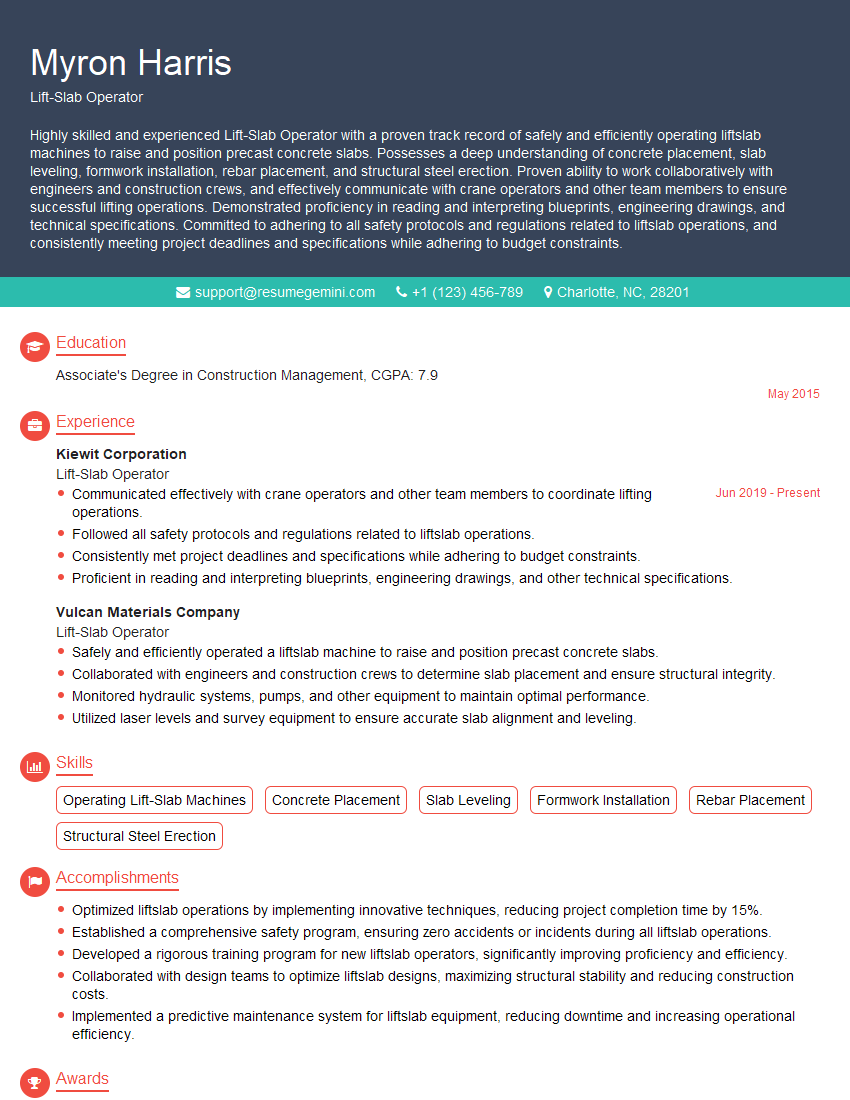

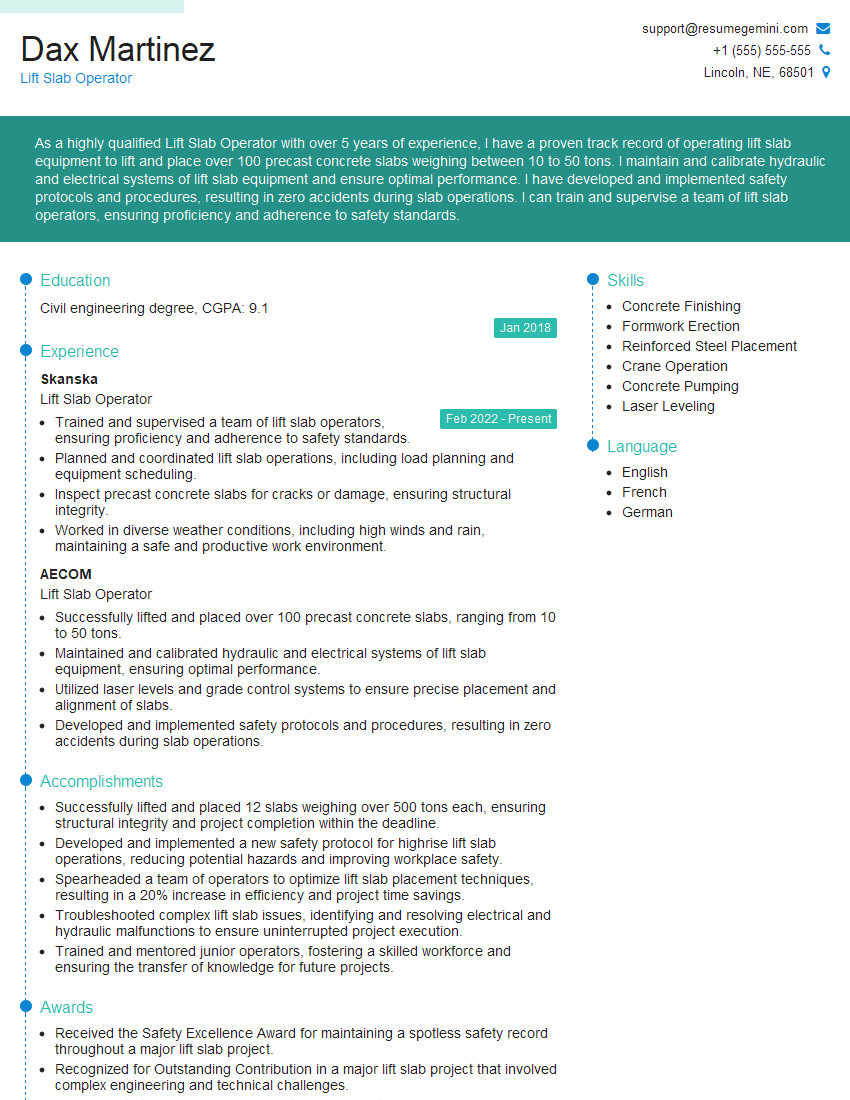

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lift-Slab Operator

1. Explain the process of lifting a slab using a hydraulic jacking system.

The process of lifting a slab using a hydraulic jacking system involves the following steps:

- Preparation: The area around the slab is cleared, and the jacking system is assembled according to the manufacturer’s instructions.

- Jacking: The hydraulic jacks are positioned under the slab, and the pumping unit is used to apply pressure to the jacks. This raises the slab in a controlled and gradual manner.

- Leveling: As the slab is lifted, it is leveled using laser levels or other instruments to ensure that it is lifted evenly and remains level.

- Locking: Once the slab has reached its desired height, it is locked into place using wedges or other locking mechanisms.

2. What are the key safety precautions that must be taken when operating a lift-slab machine?

- Ensure proper training and certification: Operators must be trained and certified to operate lift-slab machines.

- Inspect the machine before use: Prior to each use, the machine should be inspected for any damage or defects.

- Clear the work area: Remove any debris or obstructions from the work area to prevent tripping or other hazards.

- Check the hydraulic system: Ensure that the hydraulic system is functioning properly and there are no leaks.

- Maintain clear communication: Establish clear communication protocols between the operator, spotters, and other crew members.

3. How do you determine the appropriate jacking pressure for a given slab?

The appropriate jacking pressure for a given slab is determined based on several factors, including:

- Slab weight: The weight of the slab is a primary factor in determining the jacking pressure required.

- Jacking system capacity: The capacity of the jacking system, including the jacks and pumping unit, must be sufficient to lift the weight of the slab.

- Site conditions: The ground conditions and any obstacles or obstructions at the site can also affect the jacking pressure.

4. Describe the different types of lift-slab construction methods.

There are three main types of lift-slab construction methods:

- Conventional lift-slab method: In this method, the slabs are cast on the ground and then lifted into place.

- Tilt-up method: In this method, the slabs are cast on the ground and then tilted into place.

- Jump-form method: In this method, the slabs are cast in place as the structure is built.

5. What are the common problems that can occur during lift-slab operations?

Some common problems that can occur during lift-slab operations include:

- Slab cracking: This can occur due to excessive jacking pressure, uneven lifting, or inadequate support.

- Hydraulic system failure: This can lead to a loss of pressure and difficulty in lifting the slab.

- Structural deformation: This can occur if the slab is not properly supported or if the jacking system is not properly aligned.

6. How do you troubleshoot and resolve common lift-slab problems?

Troubleshooting and resolving common lift-slab problems involves the following steps:

- Identify the problem: Determine the cause of the problem by observing the symptoms and reviewing the work procedures.

- Take corrective action: Implement appropriate measures to resolve the problem, such as adjusting jacking pressure, repairing hydraulic leaks, or providing additional support.

- Monitor and evaluate: Monitor the situation to ensure that the problem has been resolved and that there are no further issues.

7. What are the latest advancements and technologies in lift-slab construction?

The lift-slab construction industry is continuously evolving, with new advancements and technologies emerging. Some recent developments include:

- Automated lifting systems: These systems use sensors and computer controls to automate the lifting process, improving safety and efficiency.

- Lightweight materials: The use of lightweight materials, such as fiber-reinforced concrete, can reduce the weight of slabs and make them easier to lift.

- Sustainable practices: The industry is adopting sustainable practices, such as using recycled materials and implementing energy-efficient lifting systems.

8. What is your experience in working on large-scale lift-slab projects?

I have been involved in several large-scale lift-slab projects, including the construction of a high-rise office building and a major sports stadium. In these projects, I was responsible for:

- Operating and maintaining the lift-slab machines

- Monitoring the lifting process and ensuring safety

- Troubleshooting and resolving any problems that arose during the lifting operations

9. How do you stay updated on the latest industry standards and best practices for lift-slab construction?

I stay updated on the latest industry standards and best practices for lift-slab construction by:

- Attending industry conferences and workshops

- Reading trade publications and technical articles

- Participating in online forums and discussions

- Consulting with manufacturers and experts in the field

10. Why are you interested in working for our company?

I am interested in working for your company because I am impressed by your company’s reputation for excellence in the construction industry. I believe that my skills and experience in lift-slab construction would be a valuable asset to your team. I am eager to contribute to the success of your company and to continue developing my skills in this field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lift-Slab Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lift-Slab Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lift-Slab Operators are responsible for the safe and efficient operation of lift-slab machines, which are used to lift and place precast concrete slabs during construction projects. Key job responsibilities include:

1. Operating Lift-Slab Machines

Lift-Slab Operators must be able to safely and efficiently operate lift-slab machines. This includes being able to control the machine’s movements, as well as the lifting and placing of concrete slabs.

- Control the movement of the lift-slab machine, including lifting, lowering, and transporting concrete slabs.

- Ensure that the machine is properly maintained and in good working order.

2. Preparing the Construction Site

Lift-Slab Operators must also be able to prepare the construction site for the placement of concrete slabs. This includes clearing the site of debris, as well as setting up the lift-slab machine.

- Clear the construction site of debris and obstacles.

- Set up the lift-slab machine and ensure that it is level and stable.

3. Placing Concrete Slabs

Lift-Slab Operators are responsible for placing concrete slabs in the correct location and at the correct elevation. This requires a high degree of precision and accuracy.

- Place concrete slabs in the correct location and at the correct elevation.

- Ensure that the slabs are level and properly aligned.

4. Inspecting Concrete Slabs

Lift-Slab Operators must also inspect concrete slabs after they have been placed. This is to ensure that the slabs are properly placed and that there are no defects.

- Inspect concrete slabs for defects, such as cracks or voids.

- Report any defects to the supervisor.

Interview Tips

To ace the interview for a Lift-Slab Operator position, it is important to be prepared and to be able to demonstrate your skills and experience. Here are a few tips to help you prepare:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website to learn about its history, mission, and values.

- Read the job description carefully and make sure you understand the key requirements.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Practice your answers out loud so that you can deliver them confidently and concisely.

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience. This includes your experience operating lift-slab machines, as well as your knowledge of construction safety. If you have any additional skills or experience that would be beneficial to the company, be sure to mention those as well.

- Highlight your experience operating lift-slab machines.

- Discuss your knowledge of construction safety.

- Mention any additional skills or experience that would be beneficial to the company.

4. Be Prepared to Talk About Your Safety Record

Safety is a top priority for Lift-Slab Operators. In your interview, be prepared to talk about your safety record and your commitment to working safely. You should also be able to discuss any safety-related training or certifications that you have.

- Be prepared to talk about your safety record.

- Discuss your commitment to working safely.

- Mention any safety-related training or certifications that you have.

Next Step:

Now that you’re armed with the knowledge of Lift-Slab Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lift-Slab Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini