Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Light Bulb Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

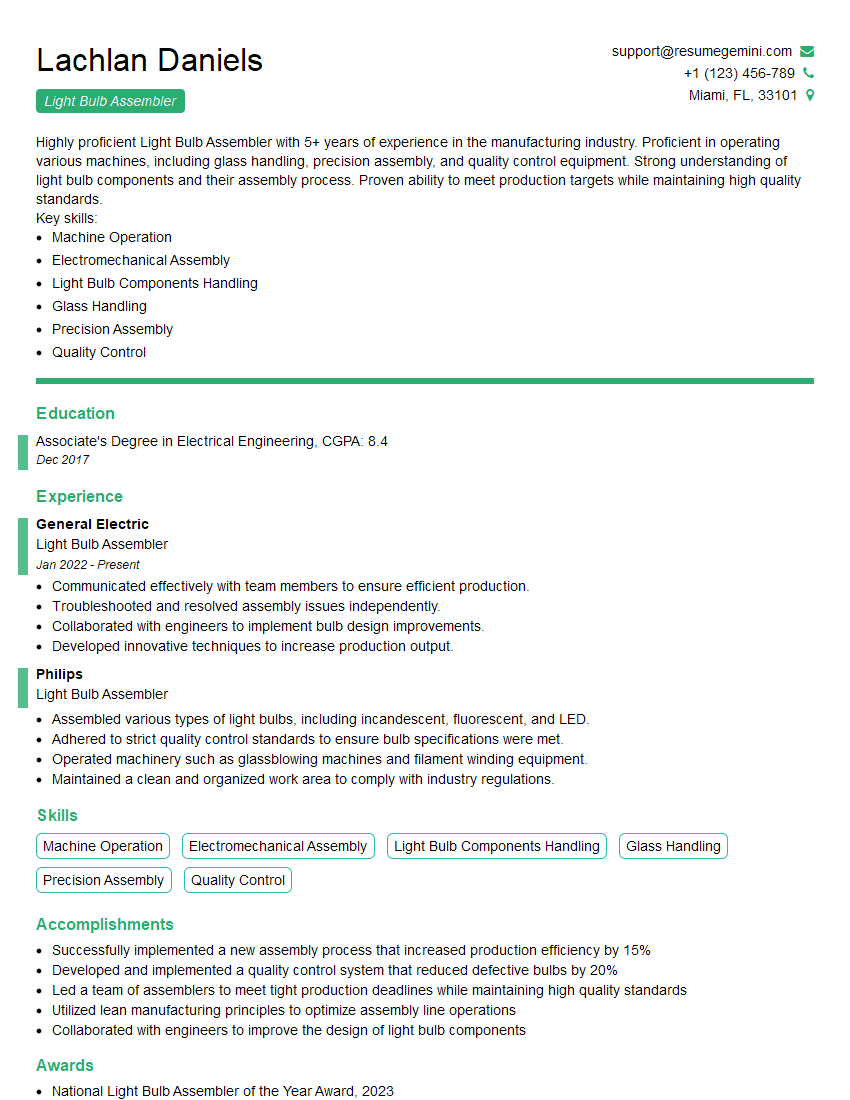

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Light Bulb Assembler

1. What are the common types of light bulbs and their applications?

- Incandescent bulbs: These are the traditional bulbs that emit light by heating a filament. They are commonly used in residential and commercial lighting applications.

- Compact fluorescent lamps (CFLs): These bulbs use a fluorescent tube to produce light. They are more energy-efficient than incandescent bulbs and have a longer lifespan.

- Light-emitting diodes (LEDs): These bulbs use semiconductor diodes to produce light. They are highly energy-efficient, have a long lifespan, and are durable.

- Halogen bulbs: These bulbs are similar to incandescent bulbs but use a halogen gas to increase their efficiency and lifespan.

2. What are the key steps involved in assembling a light bulb?

Safety

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a mask.

- Handle glass components with care to avoid breakage.

Assembly Process

- Clean the glass envelope and other components to remove any dirt or debris.

- Insert the filament or electrodes into the glass envelope.

- Seal the glass envelope around the filament or electrodes using a suitable sealant.

- Attach the base to the glass envelope.

- Inspect the bulb for any defects or damage.

- Package and label the bulb for shipment.

3. How do you ensure the quality of assembled light bulbs?

- Follow established assembly procedures and quality control standards.

- Inspect components and materials before assembly to identify any defects.

- Use calibrated equipment and tools to ensure accurate assembly.

- Conduct in-process inspections to identify and correct any errors.

- Perform final inspections to ensure that the bulbs meet specifications and quality requirements.

- Document all inspection results and corrective actions taken.

4. What are the potential hazards associated with working with light bulbs and how do you mitigate them?

- Electrical hazards: Ensure proper grounding and insulation to prevent electrical shocks.

- Glass hazards: Handle glass components with care to avoid cuts or punctures. Wear appropriate PPE and use safe handling techniques.

- Chemical hazards: Use appropriate ventilation and PPE to protect against exposure to harmful chemicals used in manufacturing or assembly.

- Ergonomic hazards: Implement proper lifting techniques and use ergonomic tools to prevent strain or injury.

5. What types of soldering techniques are used in light bulb assembly and when are they applied?

- Wave soldering: Used for high-volume production of PCBs. Involves passing the PCB through a molten solder wave.

- Hand soldering: Used for smaller batches or delicate components. Involves manually applying solder using a soldering iron.

- Reflow soldering: Used for surface-mount components. Involves heating the PCB to melt solder paste and form solder joints.

6. How do you troubleshoot common defects in light bulbs and identify their root causes?

- Filament failure: Check for broken or loose filaments. Root causes could be excessive vibration, improper assembly, or material defects.

- Glass envelope damage: Inspect for cracks or chips. Root causes could be mishandling, improper sealing, or thermal stress.

- Base connection issues: Ensure proper contact between the bulb and socket. Root causes could be bent or corroded contacts, loose connections, or incompatible base types.

7. Explain the importance of accuracy and precision in light bulb assembly.

- Accuracy: Critical for ensuring that the bulb meets the required specifications, such as wattage, voltage, and color temperature.

- Precision: Essential for consistency in assembly, ensuring that all bulbs are manufactured to the same high standards.

- Customer satisfaction: Accurate and precise assembly leads to high-quality bulbs that meet customer expectations and reduce returns.

8. Describe your experience in working with different types of light bulb manufacturing equipment.

- Assembly machines: Experience in operating automated assembly machines for high-volume production.

- Testing equipment: Familiar with using equipment for testing light bulb performance, such as photometers and life-testing devices.

- Inspection tools: Proficient in using tools for visual inspection, such as microscopes and magnifying glasses.

9. How do you maintain and calibrate equipment used in light bulb assembly?

- Follow manufacturer’s instructions for maintenance and calibration.

- Regularly clean and inspect equipment to ensure proper operation.

- Use certified calibration standards to verify accuracy of measuring devices.

- Document all maintenance and calibration activities for traceability and compliance.

10. What are your quality control procedures for ensuring that assembled light bulbs meet specifications?

- Establish clear specifications and tolerances for all critical dimensions and performance parameters.

- Implement in-process inspections to identify and correct any deviations from specifications.

- Conduct final inspections to verify compliance with all quality requirements.

- Maintain records of all inspection results and corrective actions taken.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Light Bulb Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Light Bulb Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Light Bulb Assemblers play a crucial role in the manufacturing process of light bulbs by assembling various components to create a functional final product. Their primary responsibilities include:

1. Bulb Assembly

Assembling light bulb components such as the glass envelope, filament, and base.

2. Filament Handling

Accurately positioning and securing the filament within the glass envelope.

3. Glass Envelope Inspection

Inspecting glass envelopes for defects, scratches, or other imperfections.

4. Base Attachment

Attaching the base to the glass envelope, ensuring secure and proper alignment.

5. Leakage Testing

Conducting leakage tests to ensure the light bulb is airtight and meets quality standards.

6. Packaging and Labeling

Packaging and labeling completed light bulbs according to specifications.

Interview Tips

Preparing for a Light Bulb Assembler interview requires careful consideration of both the job responsibilities and the company’s expectations. Here are some essential tips and hacks to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific Light Bulb Assembler position you are applying for. This will help you understand their products, culture, and the requirements of the role.

2. Emphasize Attention to Detail

Highlight your meticulous attention to detail and accuracy, as these are crucial qualities for Light Bulb Assemblers. Provide specific examples of how you have consistently met high-quality standards in previous work.

3. Showcase Manual Dexterity

Demonstrate your manual dexterity and coordination by discussing your experience in handling small components or assembling similar products. This will show the interviewer your ability to perform the precise tasks required.

4. Highlight Quality Assurance Experience

If you have experience in quality assurance or inspection, emphasize this during the interview. Light Bulb Assemblers play a significant role in ensuring product quality, and showcasing your knowledge in this area will be beneficial.

5. Prepare for Technical Questions

Review basic electrical concepts and the manufacturing process of light bulbs. Prepare for questions related to the types of light bulbs, their components, and any safety precautions you have taken in a similar role.

6. Practice Sample Questions

Practice answering common interview questions such as “Tell me about your experience in assembling electrical components” or “Describe a time when you had to ensure the quality of a product.” This will help you respond confidently and concisely.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Light Bulb Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!