Are you gearing up for a career in Lime Kiln and Recausticizing Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lime Kiln and Recausticizing Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

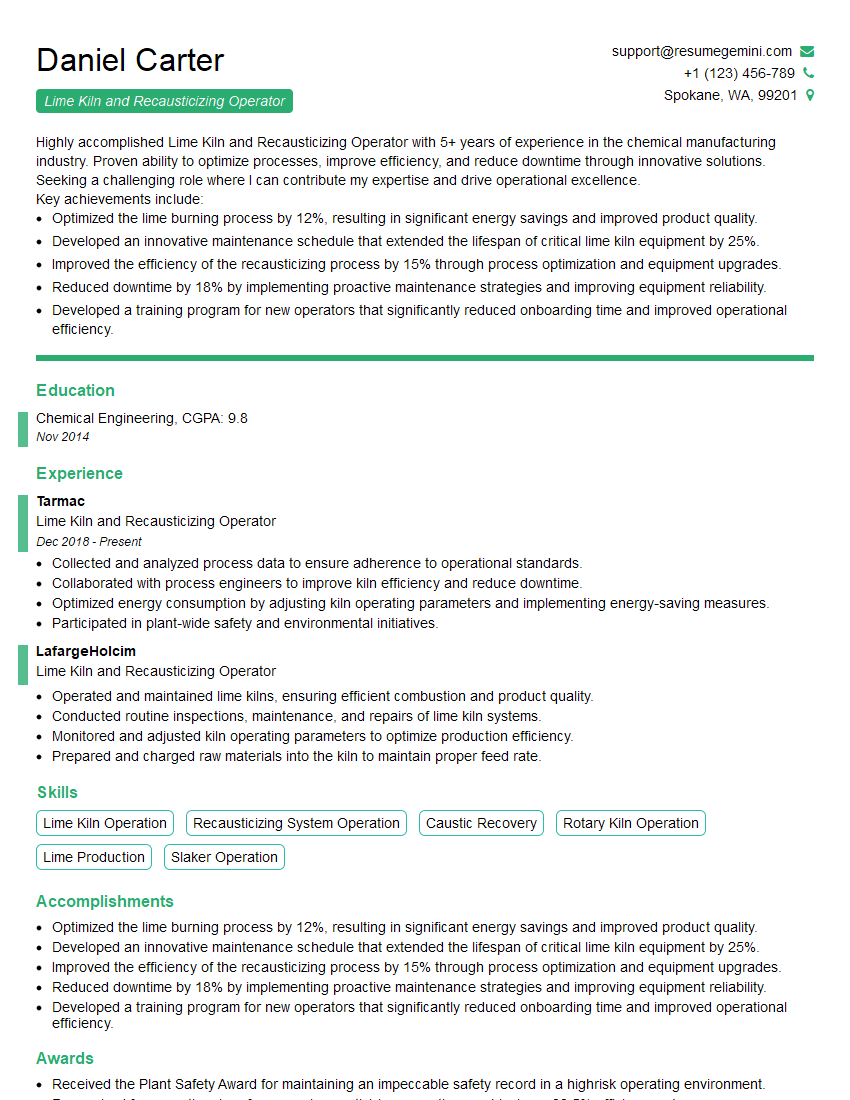

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lime Kiln and Recausticizing Operator

1. Describe the primary responsibilities of a Lime Kiln and Recausticizing Operator.

Answer: As a Lime Kiln and Recausticizing Operator, my primary responsibilities include:

- Operating and monitoring lime kilns and recausticizing systems to produce lime and caustic soda.

- Maintaining equipment, including kilns, slakers, causticizers, and evaporators.

- Conducting process control tests and monitoring parameters to ensure optimum performance.

- Troubleshooting and resolving operational issues, ensuring smooth production.

2. Explain the process of lime burning in a kiln.

Kiln Operation

- Raw limestone is fed into the preheater or precalciner.

- Limestone enters kiln and travels downward through the calcination zone where it loses moisture and decomposes into lime.

Chemical Reaction

- The decomposition of calcium carbonate (limestone) in the kiln occurs at high temperatures.

- CaCO3 + Heat → CaO (lime) + CO2 (carbon dioxide)

3. How do you ensure the quality of lime produced in the kiln?

Answer: To ensure the quality of lime produced, I follow these practices:

- Monitor kiln temperature and pressure to maintain optimal conditions for calcination.

- Regularly sample and analyze lime for chemical composition, such as calcium oxide content and impurities.

- Make adjustments to the kiln feed and operating parameters as needed to meet product specifications.

- Follow established quality control procedures and adhere to industry standards.

4. Describe the recausticizing process and its role in caustic soda production.

Answer: The recausticizing process is crucial for caustic soda production and involves the following steps:

- Slaking of lime (CaO) with water to form calcium hydroxide (Ca(OH)2)

- Reacting calcium hydroxide with sodium carbonate (Na2CO3) to form caustic soda (NaOH)

- Separating the caustic soda solution from the calcium carbonate precipitate

- Ca(OH)2 + Na2CO3 → 2NaOH + CaCO3

5. How do you control the concentration of caustic soda produced in the recausticizing process?

Answer: Controlling the concentration of caustic soda in the recausticizing process requires careful monitoring and adjustment:

- Monitor the caustic soda concentration using titration or conductivity measurements.

- Adjust the ratio of lime to sodium carbonate fed into the process based on test results.

- Ensure proper mixing and reaction time to maximize conversion.

- Control the temperature and pressure of the process to optimize reaction efficiency.

6. Explain the importance of safety procedures in a lime kiln and recausticizing plant.

Answer: Safety procedures in a lime kiln and recausticizing plant are paramount due to the hazardous nature of the processes and materials involved:

- High temperatures, caustic chemicals, and rotating equipment pose significant risks.

- Following established safety protocols, wearing appropriate PPE, and adhering to lock-out/tag-out procedures is crucial.

- Regular safety training and emergency response drills ensure operators are prepared to handle potential hazards.

7. How do you troubleshoot common issues encountered in lime kiln or recausticizing operations?

Answer: Troubleshooting common issues in lime kiln and recausticizing operations requires a systematic approach:

- Identify the problem and its symptoms accurately.

- Analyze process parameters, equipment status, and recent changes.

- Consult technical manuals, consult with colleagues, or seek expert advice.

- Implement appropriate corrective actions and monitor the results.

8. Describe preventive maintenance practices you follow to ensure smooth operation of equipment in the plant.

Answer: To ensure smooth plant operation, I prioritize preventive maintenance practices:

- Regularly inspect and lubricate equipment to minimize wear and tear.

- Schedule proactive maintenance tasks based on manufacturer recommendations and operating hours.

- Monitor equipment performance and identify potential issues early on.

- Keep detailed maintenance records and track equipment history.

9. How do you stay updated with the latest advancements and best practices in the lime and caustic soda industry?

Answer: To stay current with industry advancements, I engage in continuous learning:

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussions.

- Network with industry professionals and seek guidance from mentors.

10. How do you handle multiple tasks and prioritize your responsibilities effectively in a fast-paced plant environment?

Answer: In a demanding plant environment, I prioritize my responsibilities and manage multiple tasks efficiently:

- Develop a clear understanding of priorities and timelines.

- Break down large tasks into manageable chunks.

- Delegate responsibilities to team members when appropriate.

- Use technology, such as task management tools, to stay organized.

- Communicate effectively with colleagues and supervisors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lime Kiln and Recausticizing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lime Kiln and Recausticizing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

## Key Job Responsibilities Lime Kiln Operation * Monitor and control the lime kiln’s operating parameters, including temperature, pressure, and fuel consumption. * Adjust controls to optimize lime production, quality, and energy efficiency. * Inspect and maintain kiln equipment, including conveyors, burners, and instrumentation. * Troubleshoot and resolve operational issues, ensuring smooth and continuous production. Recausticizing Operation * Operate the causticizing plant, including white liquor preparation, milk of lime production, and sludge filtration. * Monitor and control process variables such as temperature, pH, and solids content. * Optimize chemical reactions to maximize lime recovery and minimize waste generation. * Troubleshoot and resolve process deviations, maintaining plant efficiency and minimizing downtime. Other Responsibilities * Conduct regular inspections and preventive maintenance of all plant equipment. * Comply with safety regulations and protocols, ensuring a safe working environment. * Maintain accurate records and documentation related to plant operations. * Participate in continuous improvement initiatives to enhance efficiency and productivity. ## Interview Preparation Tips ### Research the Company and Industry * Thoroughly review the company’s website, news releases, and social media presence to understand their business, culture, and values. * Research the paper and pulp industry, including market trends, key players, and best practices. ### Study the Job Description * Carefully analyze the job description to identify key responsibilities, skills, and qualifications. * Prepare examples of your experience and accomplishments that align with the requirements. * Practice articulating how your skills and knowledge match the position’s demands. ### Prepare Questions * Prepare insightful questions for the interviewer to demonstrate your interest, enthusiasm, and preparation. * Questions can focus on the company’s goals, industry challenges, and opportunities for growth. ### Practice Your Answers * Use the STAR method (Situation, Task, Action, Result) to structure your interview answers. * Provide specific and quantifiable examples to showcase your skills and accomplishments. * Practice your answers in front of a mirror or with a friend to improve delivery and build confidence. ### Dress Professionally and Punctually * First impressions matter, so dress professionally and arrive on time for your interview. * Choose attire that conveys confidence and respect for the company and the interviewer. ### Follow-Up * After the interview, send a thank-you note to the interviewer within 24 hours. * Express your appreciation for their time and reiterate your interest in the position. * Mention any additional information or insights that you may have forgotten to share during the interview.Next Step:

Now that you’re armed with the knowledge of Lime Kiln and Recausticizing Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lime Kiln and Recausticizing Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini