Are you gearing up for an interview for a Lime Sludge Kiln Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lime Sludge Kiln Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

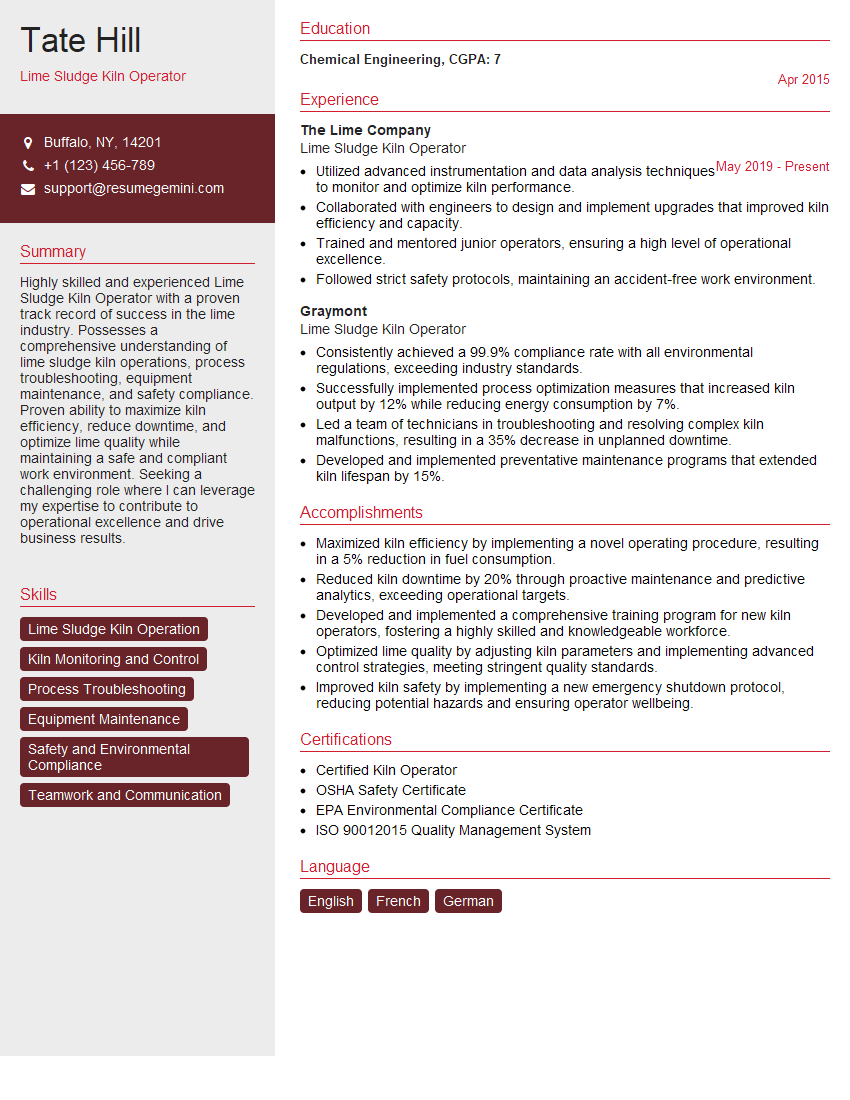

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lime Sludge Kiln Operator

1. Explain the basic principle of operation of a lime sludge kiln.

A lime sludge kiln is a type of rotary kiln used to convert lime sludge, a waste product from water treatment plants, into quicklime. Quicklime is then used in a variety of industrial processes, such as steelmaking and glass manufacturing. The basic principle of operation of a lime sludge kiln is as follows:

- Lime sludge is fed into the kiln at the feed end.

- The kiln is heated to a high temperature, typically between 1000°C and 1200°C.

- The heat causes the lime sludge to decompose, releasing carbon dioxide gas and water vapor.

- The quicklime product is discharged from the kiln at the discharge end.

2. What are the key operating parameters of a lime sludge kiln?

Temperature

- The temperature of the kiln is critical to the process. Too low a temperature will not allow the lime sludge to decompose properly, while too high a temperature can damage the kiln.

Feed rate

- The feed rate of the lime sludge is also important. Too high a feed rate can overload the kiln, while too low a feed rate can result in underutilization of the kiln.

Kiln speed

- The speed of the kiln rotation is another important operating parameter. Too high a speed can cause the lime sludge to be carried out of the kiln before it has had a chance to decompose, while too low a speed can result in the lime sludge sticking to the kiln walls.

3. What are the common problems that can occur in the operation of a lime sludge kiln?

There are a number of common problems that can occur in the operation of a lime sludge kiln, including:

- Caking of the lime sludge

- Sticking of the lime sludge to the kiln walls

- Overheating of the kiln

- Underheating of the kiln

- Mechanical problems with the kiln

4. What are the safety precautions that must be taken when operating a lime sludge kiln?

There are a number of safety precautions that must be taken when operating a lime sludge kiln, including:

- Wearing appropriate personal protective equipment (PPE)

- Following all operating procedures

- Being aware of the potential hazards

- Taking steps to prevent accidents

5. What is the role of a lime sludge kiln operator?

The role of a lime sludge kiln operator is to operate and maintain a lime sludge kiln. This includes:

- Monitoring the kiln’s operating parameters

- Adjusting the kiln’s operating parameters as needed

- Troubleshooting and resolving problems

- Ensuring that the kiln is operated safely

6. What qualifications are required to be a lime sludge kiln operator?

To be a lime sludge kiln operator, you typically need the following qualifications:

- A high school diploma or equivalent

- Experience in operating and maintaining industrial equipment

- Knowledge of the principles of operation of a lime sludge kiln

- Ability to work independently and as part of a team

7. What is the average salary for a lime sludge kiln operator?

The average salary for a lime sludge kiln operator is around $50,000 per year.

8. What is the job outlook for lime sludge kiln operators?

The job outlook for lime sludge kiln operators is expected to be good over the next few years. This is due to the increasing demand for lime products in a variety of industries.

9. What are the benefits of working as a lime sludge kiln operator?

There are a number of benefits to working as a lime sludge kiln operator, including:

- Good pay

- Job security

- Opportunities for advancement

- A chance to make a difference in the environment

10. What are the challenges of working as a lime sludge kiln operator?

There are also a number of challenges to working as a lime sludge kiln operator, including:

- Working in a hot and dusty environment

- Working with hazardous materials

- Working long hours

- Working in a remote location

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lime Sludge Kiln Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lime Sludge Kiln Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lime Sludge Kiln Operators are responsible for the safe and efficient operation of lime sludge kilns. They monitor and control the kiln’s temperature, pressure, and other operating conditions to ensure that the lime sludge is properly calcined.

1. Monitor and control kiln operating conditions

Lime Sludge Kiln Operators must constantly monitor and control the kiln’s operating conditions to ensure that the lime sludge is properly calcined. This includes monitoring the kiln’s temperature, pressure, and other operating conditions.

- Monitor and adjust the kiln’s temperature to ensure that the lime sludge is calcined properly.

- Monitor and adjust the kiln’s pressure to ensure that the lime sludge is calcined properly.

- Monitor and adjust the kiln’s other operating conditions to ensure that the lime sludge is calcined properly.

2. Inspect and maintain kiln equipment

Lime Sludge Kiln Operators must regularly inspect and maintain the kiln’s equipment to ensure that it is operating properly. This includes inspecting the kiln’s burners, refractory lining, and other equipment.

- Inspect the kiln’s burners to ensure that they are operating properly.

- Inspect the kiln’s refractory lining to ensure that it is in good condition.

- Inspect the kiln’s other equipment to ensure that it is operating properly.

3. Troubleshoot and repair kiln problems

Lime Sludge Kiln Operators must be able to troubleshoot and repair kiln problems. This includes identifying the source of the problem and taking steps to correct it.

- Identify the source of the kiln problem.

- Take steps to correct the kiln problem.

- Monitor the kiln to ensure that the problem has been corrected.

4. Follow safety procedures

Lime Sludge Kiln Operators must follow all safety procedures to ensure their safety and the safety of others. This includes wearing proper safety gear and following all safety protocols.

- Wear proper safety gear.

- Follow all safety protocols.

- Report any safety concerns to their supervisor.

Interview Tips

Preparing for an interview for a Lime Sludge Kiln Operator position can be daunting, but with the right strategies and preparation, you can increase your chances of success. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to the interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, its products or services, and the specific requirements of the position. You can find this information on the company’s website, in industry publications, or by talking to people who work for the company.

- Visit the company’s website to learn about their history, mission, and values.

- Read industry publications to learn about the company’s products or services.

- Talk to people who work for the company to get their insights on the company culture and the position you are applying for.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions.

- Practice your answers out loud so that you can deliver them confidently and concisely.

- Ask a friend or family member to give you feedback on your answers.

3. Be prepared to talk about your skills and experience

The interviewer will want to know about your skills and experience, so it is important to be prepared to talk about them in detail. Be sure to highlight your skills and experience that are most relevant to the position you are applying for.

- Make a list of your skills and experience.

- Highlight your skills and experience that are most relevant to the position you are applying for.

- Be prepared to provide specific examples of your skills and experience.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress in a suit or business casual attire.

- Arrive for your interview on time.

- Be polite and respectful to the interviewer.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lime Sludge Kiln Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lime Sludge Kiln Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.