Are you gearing up for an interview for a Linderman Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Linderman Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

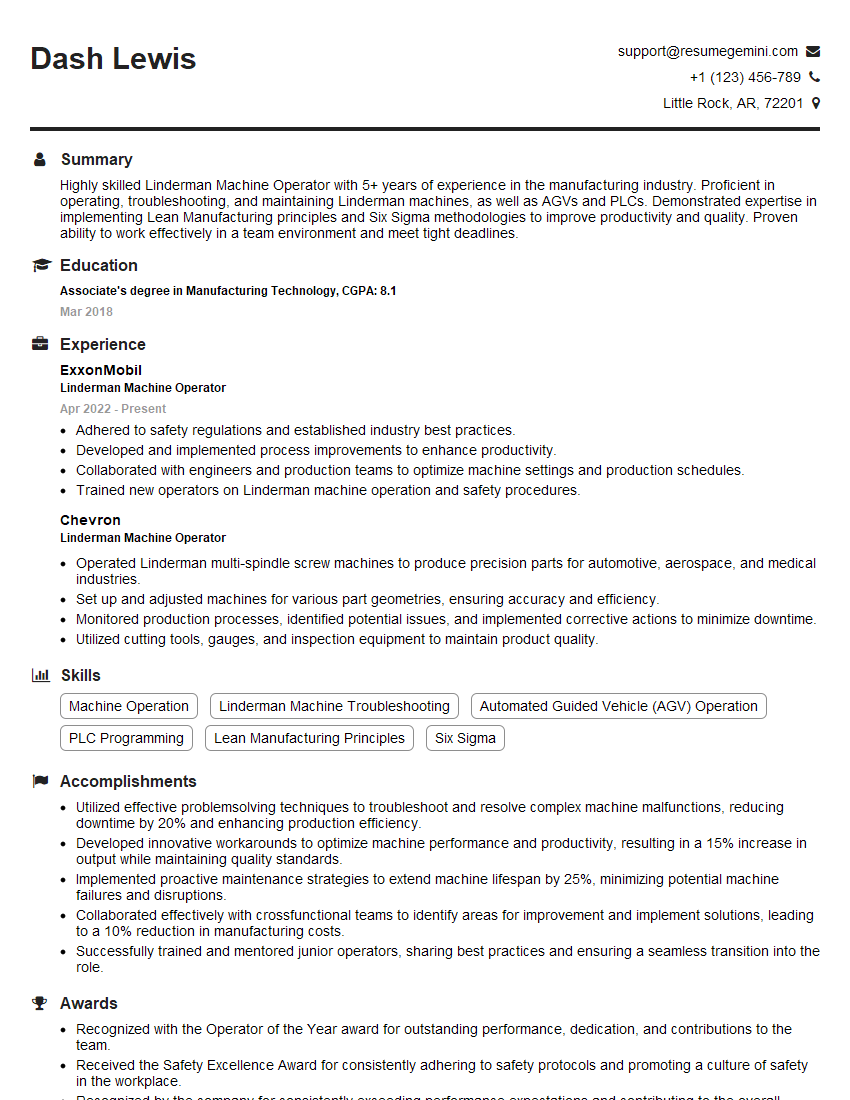

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Linderman Machine Operator

1. Describe the key responsibilities of a Linderman Machine Operator?

- Operate and monitor Linderman machines to produce precision parts.

- Set up machines, adjust tooling, and select appropriate cutting parameters.

- Inspect parts for quality and accuracy, using measuring tools.

- Maintain and clean machines and work area, ensuring optimal performance.

- Troubleshoot machine malfunctions and perform minor repairs as needed.

2. Explain the different types of cutting operations performed on a Linderman machine?

Milling

- Using a rotating cutter to remove material from the workpiece.

- Can create various shapes and profiles.

Drilling

- Creating holes of different sizes and depths.

- Requires precise positioning and tool selection.

Boring

- Enlarging or finishing existing holes.

- Ensures accurate dimensions and surface finish.

Tapping

- Creating internal threads for fasteners.

- Requires proper tool selection and cutting parameters.

3. How do you ensure the accuracy and quality of parts produced on a Linderman machine?

- Regularly calibrate the machine and cutting tools.

- Use precision measuring tools and gauges to verify dimensions.

- Inspect parts visually and through touch for surface finish and defects.

- Follow established quality control procedures and tolerances.

- Maintain a clean and organized work area to minimize errors.

4. What are the safety precautions you take when operating a Linderman machine?

- Wear appropriate personal protective equipment (PPE).

- Ensure proper machine guarding and interlocks are in place.

- Never operate the machine under the influence of substances.

- Follow established safety protocols and lockout/tagout procedures.

- Be aware of the potential hazards associated with rotating machinery.

5. How do you maintain and troubleshoot a Linderman machine?

- Regularly lubricate and clean the machine.

- Inspect cutting tools for wear or damage.

- Troubleshoot common malfunctions, such as tool breakage, vibration, and coolant leaks.

- Perform scheduled maintenance tasks based on manufacturer’s guidelines.

- Consult with qualified technicians or supervisors for complex issues.

6. What experiences have you had in programming and operating CNC Linderman machines?

- Describe specific projects where you programmed and operated CNC Linderman machines.

- Mention the types of parts you produced and the complexity of the operations.

- Explain your proficiency in using CNC programming software and control systems.

7. How do you handle the setup and changeover of different jobs on a Linderman machine?

- Describe the steps involved in setting up and changing over to different jobs.

- Explain how you ensure accurate setup and avoid errors.

- Discuss the importance of proper tool selection and optimization.

8. Describe your experience in using coordinate measuring machines (CMMs) to inspect parts produced on a Linderman machine.

- Explain the principles and operation of CMMs.

- Discuss how CMMs are used to measure and verify the dimensions of parts.

- Provide examples of how you have used CMMs in your previous role.

9. How do you stay up-to-date with the latest advancements in Linderman machine technology and best practices?

- Mention industry conferences, trade shows, and workshops attended.

- Discuss technical articles, journals, and online resources consulted.

- Explain how you incorporate new knowledge and skills into your work.

10. What are your strengths and weaknesses as a Linderman Machine Operator?

- Highlight your technical skills, experience, and attention to detail.

- Identify areas where you are confident and proficient.

- Acknowledge weaknesses and explain how you are working to improve.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Linderman Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Linderman Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Linderman Machine Operator role is pivotal in a manufacturing environment, responsible for managing the operations, maintenance, and optimization of the Linderman machine.

1. Machine Operation

Skilled in maneuvering the Linderman machine, ensuring adherence to established process parameters and achieving precise product specifications.

- Setting up and operating the machine, monitoring its performance, and troubleshooting any issues that may arise.

- Adjusting machine settings, such as speed, feed rate, and depth of cut, to ensure optimal performance.

2. Quality Control

Proficient in implementing and adhering to quality control procedures, ensuring products meet or exceed customer standards.

- Inspecting products for defects, taking corrective actions as needed, and maintaining accurate records of quality checks.

- Analyzing production data to identify areas for improvement, implementing corrective actions to enhance product quality.

3. Preventative Maintenance

Performs regular and thorough maintenance on the Linderman machine to ensure peak performance and prevent breakdowns.

- Cleaning, lubricating, and adjusting machine components as per established schedules.

- Inspecting machine parts for wear or damage, and replacing or repairing parts as necessary.

4. Safety Compliance

Observes and enforces all safety regulations and guidelines to maintain a safe working environment.

- Following established safety procedures when operating the machine.

- Wearing appropriate personal protective equipment and maintaining a clean and organized work area.

Interview Tips

Preparing for an interview for the Linderman Machine Operator position requires thoroughness and showcasing your skills and knowledge.

1. Research the Company and Role

Before the interview, delve into the company’s website, social media, and industry news to gain insights into their culture, values, and recent developments. This demonstrates your interest and commitment to the role.

2. Practice Common Interview Questions

Anticipate common interview questions related to your skills, experience, and knowledge of the Linderman machine. Prepare thoughtful and concise responses, highlighting your strengths and abilities.

3. Technical Questions Preparation

Prepare for technical questions specific to the Linderman machine. Understand its operation, maintenance procedures, and troubleshooting techniques. Showcase your expertise and ability to handle technical challenges.

4. Highlight Safety Awareness

Emphasize your commitment to safety by highlighting your understanding of safety regulations and practices in a manufacturing environment. Discuss your experience in adhering to safety protocols and maintaining a safe work area.

5. Show Enthusiasm and Ask Questions

Convey your enthusiasm for the role and the company. Ask thoughtful questions that demonstrate your interest in the position and the industry. This shows your engagement and eagerness to learn.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Linderman Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!