Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Line Assembly Utility Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

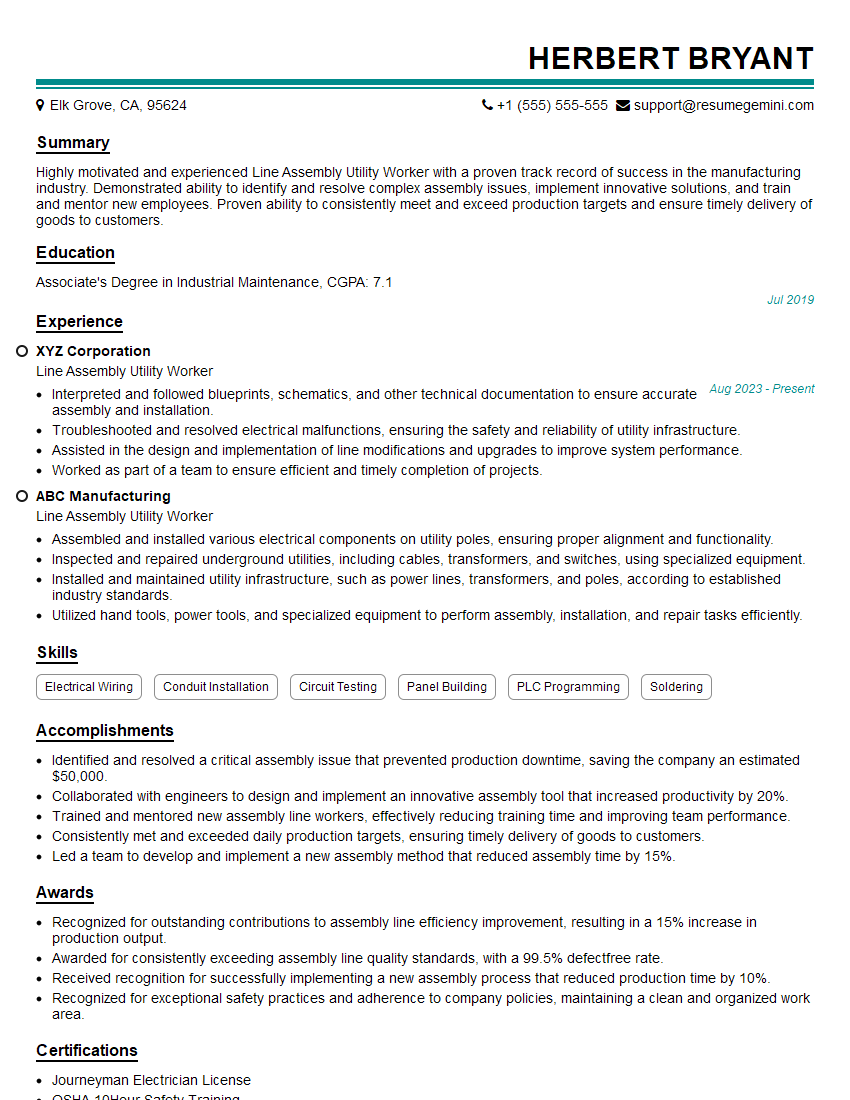

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Line Assembly Utility Worker

1. What are the main responsibilities of a Line Assembly Utility Worker?

As a highly-skilled Line Assembly Utility Worker with a strong understanding of manufacturing processes, I am adept at assembling, installing, and testing various components and systems within a production line setting. My key responsibilities include:

- Assembling components and parts according to specifications and blueprints.

- Installing and connecting electrical, mechanical, and pneumatic systems.

- Conducting functional tests to ensure proper operation of assembled products.

- Identifying and troubleshooting assembly problems promptly and efficiently.

- Adhering to safety protocols and maintaining a clean and organized work area.

2. Describe your experience working with electrical and pneumatic systems.

Electrical Systems

- Extensive experience in wiring and connecting electrical components, including switches, sensors, and actuators.

- Knowledge of electrical theory, including Ohm’s Law, circuit analysis, and grounding principles.

- Proficient in using multimeters, oscilloscopes, and other electrical test equipment.

Pneumatic Systems

- Experience in installing, maintaining, and troubleshooting pneumatic systems, including compressors, valves, and cylinders.

- Understanding of pneumatic principles, such as pressure regulation, flow control, and air filtration.

- Skilled in using pneumatic tools and equipment, such as air wrenches and impact drivers.

3. How do you handle working in a fast-paced production environment?

I thrive in fast-paced production environments and possess the following attributes to excel in such settings:

- Strong time management skills and the ability to prioritize tasks effectively.

- Exceptional attention to detail and accuracy in performing assembly operations.

- Excellent hand-eye coordination and manual dexterity.

- A proactive approach to identifying and resolving potential issues promptly.

- The ability to work independently and as part of a team, collaborating with colleagues to meet production goals.

4. What are some of the safety protocols you follow in a manufacturing environment?

Safety is paramount in a manufacturing environment, and I strictly adhere to the following protocols to ensure the well-being of myself and others:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a hard hat.

- Following lockout/tagout procedures when working on machinery or electrical systems.

- Maintaining a clean and organized work area to minimize tripping or slipping hazards.

- Being aware of potential hazards and taking appropriate precautions to avoid accidents.

- Reporting any unsafe conditions or incidents to supervisors promptly.

5. How do you stay up-to-date with advancements in manufacturing technology?

To remain current with advancements in manufacturing technology, I engage in the following activities:

- Attending industry conferences and webinars to learn about new technologies and best practices.

- Reading industry publications and online resources.

- Seeking opportunities for training and professional development.

- Networking with other professionals in the field to exchange knowledge and ideas.

- Utilizing online platforms and forums to stay informed about emerging trends in manufacturing.

6. What is your experience with lean manufacturing principles?

I have a solid understanding of lean manufacturing principles and have successfully implemented them in previous roles. These principles include:

- Value stream mapping to identify and eliminate waste in production processes.

- Kaizen (continuous improvement) to optimize efficiency and productivity.

- Just-in-time (JIT) inventory management to reduce waste and improve cash flow.

- Total productive maintenance (TPM) to ensure equipment reliability and uptime.

- 5S (Sort, Set in Order, Shine, Standardize, Sustain) to maintain a clean and organized work environment.

7. How do you handle situations where multiple tasks need to be completed simultaneously?

In situations where multiple tasks need to be completed simultaneously, I prioritize them based on urgency and importance. I utilize the following strategies to effectively manage my workload:

- Creating a prioritized task list and breaking down large tasks into smaller, manageable steps.

- Delegating tasks to others when appropriate to ensure timely completion.

- Utilizing time management techniques, such as the Pomodoro Technique or Eisenhower Matrix.

- Staying organized and maintaining a clean workspace to minimize distractions.

- Communicating clearly with colleagues and supervisors to keep everyone informed of progress and potential delays.

8. Describe a situation where you had to troubleshoot a complex assembly problem.

In a previous role, I encountered a situation where a newly assembled product was experiencing intermittent power failures. I followed a systematic troubleshooting process to identify and resolve the issue. My approach included:

- Visually inspecting the assembly to identify any loose connections or damaged components.

- Using a multimeter to test electrical continuity and voltage levels throughout the system.

- Consulting technical manuals and schematics to understand the intended functionality of the assembly.

- Replacing suspected faulty components and retesting the system.

- Documenting the troubleshooting process and the solution to prevent recurrence.

9. What motivates you to work in the manufacturing industry?

I am passionate about working in the manufacturing industry for the following reasons:

- The opportunity to contribute to the production of tangible goods that make a difference in people’s lives.

- The satisfaction of seeing a product come to life through my own efforts and the collaboration of others.

- The challenges and rewards of working in a dynamic and ever-evolving field.

- The opportunity to learn and grow both professionally and personally.

- The pride in being part of a team that brings innovative products to market.

10. Why do you think you are the best candidate for this position?

I am confident that I am the best candidate for this Line Assembly Utility Worker position due to the following reasons:

- My proven experience in assembling, installing, and testing various components and systems.

- My strong understanding of electrical and pneumatic systems, including troubleshooting and repair.

- My ability to work efficiently and effectively in a fast-paced manufacturing environment.

- My commitment to safety and my adherence to established protocols.

- My enthusiasm for learning and my eagerness to embrace new technologies and advancements in the field.

- My strong work ethic and my dedication to delivering high-quality results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Line Assembly Utility Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Line Assembly Utility Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Line Assembly Utility Workers play a vital role in the manufacturing process, ensuring the smooth operation of assembly lines and the production of high-quality products. Their responsibilities encompass a wide range of tasks, including:

1. Assembling and Installing Components

Line Assembly Utility Workers are responsible for assembling and installing various components onto the assembly line, ensuring that they are properly aligned and secured. They work with a variety of tools and equipment, such as screwdrivers, wrenches, and torque wrenches, to complete these tasks.

- Locate and retrieve components from designated storage areas

- Assemble components according to specifications and blueprints

- Ensure proper alignment and fit of components

- Tighten bolts, nuts, and screws to specified torque

- Inspect assembled components for defects or inconsistencies

2. Performing Quality Control Checks

Line Assembly Utility Workers conduct quality control checks throughout the assembly process to ensure that products meet specifications and standards. They use measuring tools and gauges to verify dimensions, inspect for defects, and test functionality. Any discrepancies or defects are reported to supervisors for further investigation and resolution.

- Monitor assembly line for potential defects or errors

- Use measuring tools and gauges to verify dimensions and tolerances

- Visually inspect components and assemblies for flaws or inconsistencies

- Test functionality of assembled products to ensure proper operation

- Document any defects or deviations from specifications

3. Maintaining and Troubleshooting Equipment

Line Assembly Utility Workers are responsible for maintaining and troubleshooting equipment on the assembly line. They perform routine maintenance tasks, such as cleaning, lubrication, and adjustments, to prevent breakdowns and ensure efficient operation. They also troubleshoot and resolve equipment malfunctions, minimizing downtime and maintaining productivity.

- Clean and lubricate equipment regularly to prevent wear and tear

- Perform minor adjustments and repairs to maintain equipment functionality

- Identify and diagnose equipment malfunctions

- Repair or replace defective components or parts

- Calibrate and adjust equipment to ensure accuracy and precision

4. Adhering to Safety Regulations

Line Assembly Utility Workers must adhere to strict safety regulations and practices to prevent accidents and injuries. They wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs, and follow established safety protocols. They are trained to identify and mitigate potential hazards, and they report any unsafe conditions or practices to supervisors.

- Wear appropriate Personal Protective Equipment (PPE) at all times

- Follow established safety procedures and guidelines

- Identify and mitigate potential safety hazards

- Report unsafe conditions or practices to supervisors

- Stay alert and aware of surroundings to prevent accidents

Interview Tips

Preparing thoroughly for your interview is crucial to making a positive impression on potential employers. Here are some tips to help you ace your interview for a Line Assembly Utility Worker position:

1. Research the Company and Position

Research the company you’re applying to and the specific role you’re interested in. Understand their products, services, values, and industry reputation. This knowledge will enable you to tailor your answers and demonstrate your interest in the company and position.

- Visit the company’s website

- Read industry news and articles

- Learn about the company’s products or services

- Identify the key responsibilities and requirements of the position

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. Anticipate questions about your experience, skills, strengths, weaknesses, and why you’re interested in the position. Practice delivering clear and concise answers that highlight your qualifications.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Describe your experience in assembling and installing components

- How do you ensure quality in your work?

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the role of a Line Assembly Utility Worker. Quantify your accomplishments and provide specific examples of your work. Use action verbs and industry-specific terminology to demonstrate your proficiency in the field.

- Highlight your ability to assemble and install components accurately and efficiently

- Demonstrate your experience in performing quality control checks and identifying defects

- Showcase your ability to maintain and troubleshoot equipment

- Emphasize your commitment to safety and adherence to regulations

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare questions that demonstrate your understanding of the role, the industry, or the company’s culture. Avoid asking generic or personal questions.

- What are the biggest challenges facing the company in the coming year?

- How does the company promote professional development and growth?

- What are the company’s core values and how are they reflected in the workplace?

- What is the company’s commitment to sustainability?

5. Follow Up

After the interview, send a thank-you note to the interviewer. Express your appreciation for their time and reiterate your interest in the position. Briefly summarize your key qualifications and why you believe you are the right person for the job. Send the thank-you note within 24 hours of the interview.

- Thank the interviewer for their time

- Reiterate your interest in the position

- Summarize your key qualifications

- Reiterate why you’re the right person for the job

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Line Assembly Utility Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!