Feeling lost in a sea of interview questions? Landed that dream interview for Line Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Line Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

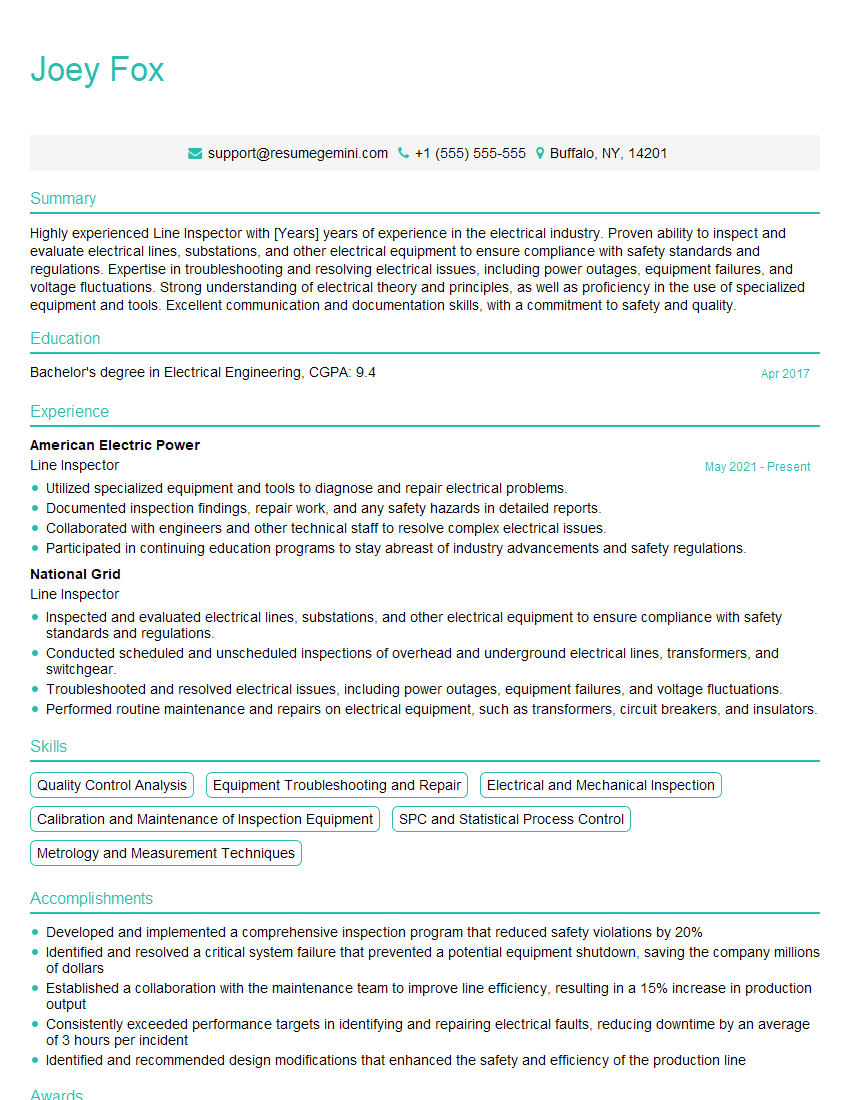

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Line Inspector

1. Explain the role and responsibilities of a Line Inspector?

As a Line Inspector, I would be responsible for ensuring the safety and integrity of overhead and underground power lines. My key duties would include:

- Inspecting and maintaining power lines to identify any potential hazards or defects.

- Troubleshooting and repairing electrical faults to restore power supply.

- Monitoring electrical equipment and systems to ensure optimal performance.

- Responding to emergency situations involving power outages or downed lines.

- Maintaining detailed records and documentation of inspections and repairs.

2. Describe the different types of power lines and their respective inspection procedures?

Overhead Power Lines

- Visually inspect towers, poles, and conductors for any damage or corrosion.

- Check for proper grounding and connections.

- Monitor vegetation growth near power lines to prevent contact.

Underground Power Lines

- Use specialized equipment to locate and inspect underground cables.

- Check for insulation damage, moisture ingress, or other faults.

- Coordinate with excavation teams to ensure safe cable exposure and repair.

3. What are the common hazards associated with power lines, and how do you mitigate them?

Common hazards include:

- Electrical shocks: Wear insulated gloves, use insulated tools, and maintain proper clearance.

- Falls: Use fall arrest equipment, climb safely, and avoid working in adverse weather conditions.

- Arc flash: Wear protective clothing, follow proper grounding procedures, and use arc flash detection systems.

- Contact with vegetation: Trim trees and shrubs near power lines, use insulated tools, and follow vegetation management protocols.

4. Explain the importance of record-keeping in line inspection?

Accurate records provide evidence of inspections, repairs, and maintenance activities. They are crucial for:

- Safety: Documenting hazards and repairs helps prevent accidents and ensures compliance with regulations.

- Maintenance planning: Records track maintenance history, allowing for efficient scheduling and resource allocation.

- Legal protection: Records provide evidence of proper inspection and maintenance practices in case of incidents or disputes.

5. Describe your experience in using line inspection equipment, such as binoculars, thermal cameras, and voltage detectors?

I have extensive experience using various line inspection tools:

- Binoculars: Inspect distant components, identify loose connections, and detect vegetation encroachment.

- Thermal cameras: Detect hot spots, loose connections, and insulation damage.

- Voltage detectors: Measure voltage levels, identify energized lines, and ensure proper grounding.

6. What is your approach to working safely in high-voltage environments?

I prioritize safety by following established protocols and using personal protective equipment (PPE):

- Adhere to lockout/tagout procedures to isolate and de-energize equipment.

- Wear insulated gloves, clothing, and headgear to prevent electrical shocks.

- Use insulated tools and maintain proper working distances from energized components.

7. Describe a challenging line inspection experience and how you resolved it?

During a remote line inspection, I encountered a fallen transmission tower due to a storm. I:

- Assessed the situation and isolated the affected section safely.

- Coordinated with emergency responders and repair crews to secure the area and begin repairs.

- Communicated with stakeholders to provide updates and restore power as quickly as possible.

8. How do you stay up-to-date with the latest industry standards and technologies in line inspection?

I actively pursue professional development through:

- Attending industry conferences and workshops.

- Reading technical publications and journals.

- Consulting with experts and colleagues.

- Participating in training programs to enhance my skills and knowledge.

9. How do you handle working in challenging weather conditions?

I am trained and equipped to work safely under various weather conditions:

- Extreme heat: Wear appropriate clothing, stay hydrated, and take breaks in shaded areas.

- Cold temperatures: Use insulated clothing and warmers, and avoid working alone in isolated areas.

- High winds: Secure equipment properly, wear protective gear, and avoid working on elevated structures.

10. What are some of the latest technological advancements in line inspection that you are familiar with?

I am familiar with the following emerging technologies:

- Drone inspection: Using unmanned aerial vehicles to provide comprehensive line inspections, reducing risk and improving efficiency.

- Thermal imaging: Detecting hidden defects and overheating components using thermal imaging cameras.

- Data analytics: Using software to analyze inspection data, identify trends, and predict potential problems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Line Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Line Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Line inspectors are responsible for ensuring that production lines are running smoothly and efficiently. They perform a variety of tasks, including:

1. Monitor production lines

Line inspectors monitor production lines to identify any potential problems. They look for things like equipment malfunctions, product defects, and safety hazards.

2. Inspect products

Line inspectors inspect products to ensure that they meet quality standards. They check for things like size, weight, and appearance.

3. Maintain production equipment

Line inspectors perform basic maintenance on production equipment. They clean and lubricate machines, and they make minor repairs.

4. Troubleshoot problems

Line inspectors troubleshoot problems when they occur. They identify the root cause of the problem and take steps to correct it.

5. Maintain records

Line inspectors maintain records of their work. They keep track of the products they inspect, the problems they identify, and the actions they take.

Interview Tips

To prepare for an interview for a line inspector position, you should focus on demonstrating your skills and experience in the following areas:

1. Quality control

Employers will be looking for candidates who have a strong understanding of quality control principles and practices. Be sure to highlight your experience in inspecting products and maintaining equipment.

- Example: You could describe a time when you identified a defect in a product and took steps to correct it.

- Example: You could also describe a time when you implemented a new quality control procedure that resulted in a reduction in defects.

2. Troubleshooting

Employers will also be looking for candidates who have strong troubleshooting skills. Be sure to highlight your experience in identifying and solving problems on production lines.

- Example: You could describe a time when you identified a problem with a machine and took steps to repair it.

- Example: You could also describe a time when you helped to improve the efficiency of a production line by identifying and eliminating bottlenecks.

3. Teamwork

Line inspectors often work as part of a team. Be sure to highlight your teamwork skills and experience.

- Example: You could describe a time when you worked with a team to solve a problem on a production line.

- Example: You could also describe a time when you helped to train a new team member.

4. Communication

Line inspectors need to be able to communicate effectively with both supervisors and other team members. Be sure to highlight your communication skills and experience.

- Example: You could describe a time when you gave a presentation to your supervisor about a quality control issue.

- Example: You could also describe a time when you helped to resolve a conflict between team members.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Line Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!