Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Line Installer-Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Line Installer-Repairer so you can tailor your answers to impress potential employers.

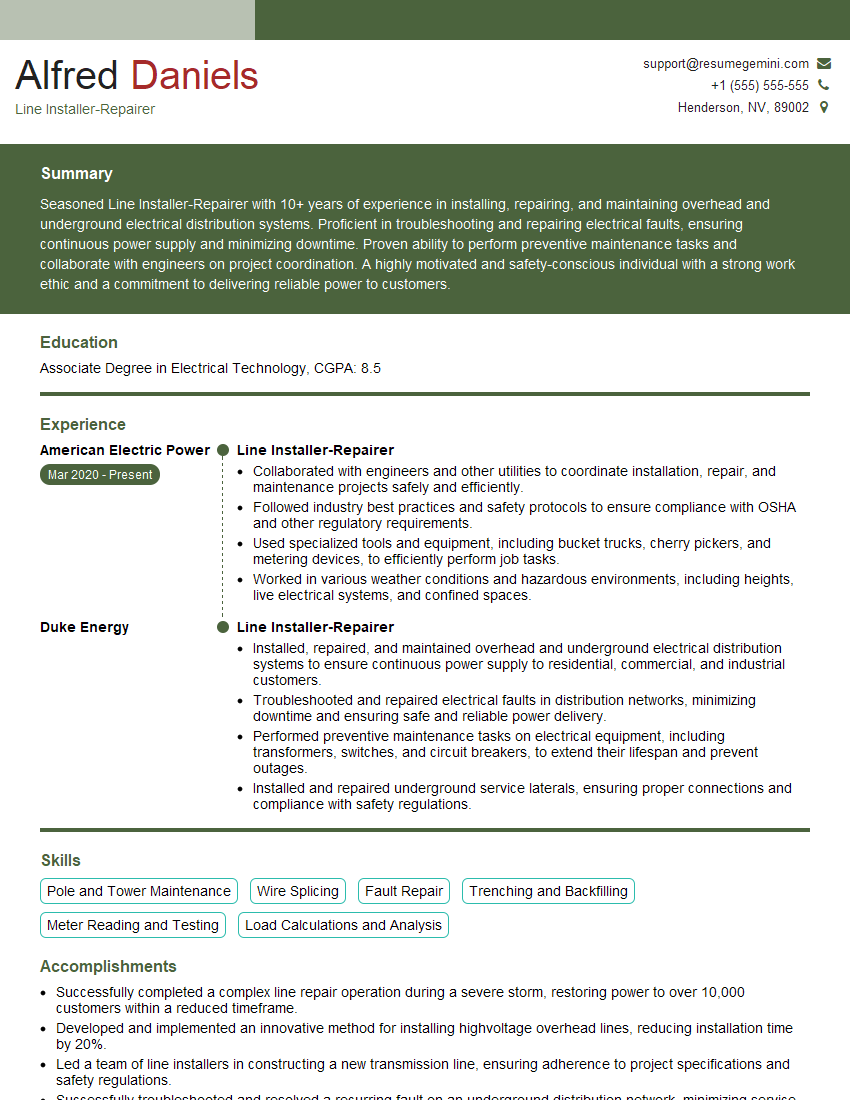

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Line Installer-Repairer

1. What is the proper procedure for installing a new power line?

The proper procedure for installing a new power line generally involves the following steps:

- Surveying the area to determine the best route for the line.

- Clearing the right-of-way of trees and other obstructions.

- Installing poles or towers to support the line.

- Stringing the conductors (wires) on the poles or towers.

- Connecting the line to the electrical grid.

- Testing the line to ensure it is safe and operating properly.

2. What are the different types of power lines?

Overhead power lines

- Carried on poles or towers.

- Typically used for long-distance transmission.

- Can be susceptible to weather-related outages.

Underground power lines

- Buried underground in conduits or ducts.

- Less susceptible to weather-related outages than overhead lines.

- More expensive to install and maintain than overhead lines.

Submarine power lines

- Laid on the bed of a body of water.

- Used to connect offshore islands or other locations that are not easily accessible by land-based power lines.

- Can be susceptible to damage from marine life, anchors, and other hazards.

3. What are the safety precautions that must be taken when working on power lines?

When working on power lines, it is crucial to follow strict safety precautions to minimize the risk of electrical shock, falls, and other accidents. These precautions include:

- Wearing proper personal protective equipment (PPE), such as insulated gloves, rubber boots, and a hard hat.

- Using insulated tools and equipment.

- Maintaining a safe distance from energized lines.

- Following established procedures for lockout/tagout.

- Having a qualified spotter present when working on energized lines.

- Being aware of weather conditions and potential hazards.

4. What are the common causes of power outages?

Power outages can be caused by a variety of factors, including:

- Storms (wind, lightning, ice, snow)

- Equipment failure (transformers, power lines, substations)

- Vehicle accidents

- Tree and vegetation contact with power lines

- Animal interference

- Intentional acts (vandalism, sabotage)

5. What are the steps involved in repairing a damaged power line?

Repairing a damaged power line involves the following general steps:

- Ensuring the safety of the work area.

- Isolating the damaged section of the line.

- Replacing or repairing the damaged components.

- Testing the repaired line to ensure it is safe and operating properly.

- Restoring power to the affected area.

6. What are the different types of insulators used in power lines?

Insulators are used to prevent electrical current from flowing from energized conductors to the ground or other objects. The most common types of insulators used in power lines include:

- Glass insulators

- Ceramic insulators

- Polymer insulators

- Composite insulators

7. What are the different types of conductors used in power lines?

Conductors are the wires that carry electrical current in power lines. The most common types of conductors used in power lines include:

- Copper conductors

- Aluminum conductors

- Steel-reinforced aluminum conductors (ACSR)

- Composite core conductors (CCCs)

8. What are the different types of towers used in power lines?

Towers are used to support power lines in areas where it is not feasible to use poles. The most common types of towers used in power lines include:

- Lattice towers

- Monopole towers

- Guyed towers

- Self-supporting towers

9. What are the different types of substations used in power lines?

Substations are used to transform voltage levels and to switch power between different circuits. The most common types of substations used in power lines include:

- Distribution substations

- Transmission substations

- Interconnection substations

10. What are the different types of maintenance activities performed on power lines?

Power lines require regular maintenance to ensure they are operating safely and reliably. Common maintenance activities performed on power lines include:

- Inspection of lines and equipment

- Testing of lines and equipment

- Cleaning and lubrication of equipment

- Replacement of damaged or worn components

- Tree trimming and vegetation management

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Line Installer-Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Line Installer-Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Line Installer-Repairers are responsible for installing, repairing, and maintaining power lines and other electrical equipment.

1. Installing New Lines and Equipment

Their duties include:

- Laying out new lines and digging trenches for underground cables

- Installing poles, transformers, and other equipment

- Stringing wires and cables

2. Repairing Existing Lines and Equipment

They also:

- Troubleshoot electrical problems

- Replace damaged wires, cables, and equipment

- Repair or replace poles and transformers

3. Maintaining Existing Lines and Equipment

Additionally, they:

- Inspect lines and equipment for damage

- Perform preventive maintenance to keep equipment in good working order

- Clear trees and other obstacles from lines

4. Other Duties

Other duties may include:

- Working with other tradespeople, such as electricians and linemen

- Following safety procedures and using appropriate protective gear

- Keeping accurate records of their work

Interview Tips

To ace an interview for a Line Installer-Repairer position, it is important to prepare in advance. Here are some tips:

1. Research the Company and the Position

Learn as much as you can about the company’s history, culture, and business goals. Also, review the job description carefully and identify the key skills and qualifications that the employer is looking for.

2. Practice Answering Common Interview Questions

Some common interview questions for Line Installer-Repairers include:

- Tell me about your experience installing and repairing power lines.

- What are some of the challenges you have faced in this role?

- How do you stay up-to-date on the latest safety procedures?

- What are your strengths and weaknesses as a Line Installer-Repairer?

3. Highlight Your Skills and Experience

In your answers, be sure to highlight your skills and experience that are relevant to the job. For example, you could discuss your experience with installing and repairing specific types of equipment, or your ability to work safely in hazardous conditions.

4. Be Enthusiastic and Professional

Show the interviewer that you are enthusiastic about the position and that you have a positive attitude. Be professional and respectful throughout the interview, and dress appropriately.

Next Step:

Now that you’re armed with the knowledge of Line Installer-Repairer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Line Installer-Repairer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini