Feeling lost in a sea of interview questions? Landed that dream interview for Line Out Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Line Out Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

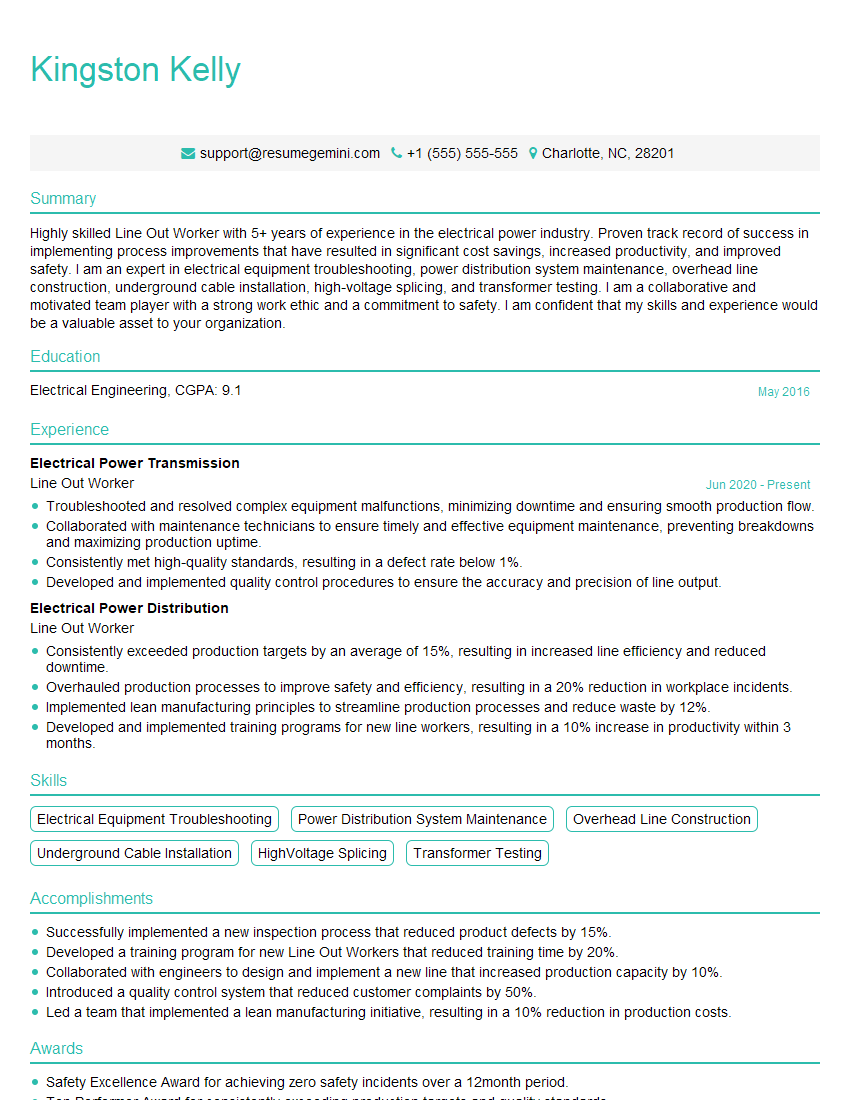

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Line Out Worker

1. What are the key responsibilities of a Line Out Worker?

- Laying out and marking electrical lines for installation.

- Terminating and connecting electrical wires and cables.

- Testing and inspecting electrical systems for safety and compliance.

- Troubleshooting and repairing electrical faults.

- Maintaining and updating electrical records and documentation.

2. Describe the different types of electrical wires and cables used in overhead line construction.

Solid Conductors

- Copper Conductors: High conductivity, ductile, and corrosion-resistant.

- Aluminum Conductors: Lightweight, high strength-to-weight ratio, but susceptible to corrosion.

- Steel Conductors: High strength, low conductivity, used for long spans and transmission lines.

Stranded Conductors

- Copper Stranded Conductors: Flexible, high conductivity, used for distribution lines.

- Aluminum Stranded Conductors: Flexible, lightweight, used for overhead service drops.

- Composite Core Conductors (ACCR): Aluminum strands wrapped around a steel core, combining strength and conductivity.

3. What are the safety precautions that must be taken when working on overhead lines?

- Wearing appropriate personal protective equipment (PPE).

- Ensuring the line is de-energized and grounded before working on it.

- Using insulated tools and equipment.

- Maintaining a safe distance from live lines.

- Following established work procedures and safety guidelines.

4. How do you determine the appropriate sag for an overhead line?

- Consider factors such as conductor type, length, temperature, and wind loading.

- Use sag charts or tables provided by manufacturers or industry standards.

- Calculate the sag using formulas that take into account the conductor’s physical properties and environmental conditions.

- Ensure that the sag is within acceptable limits to prevent line damage due to overloading or excessive tension.

5. What are the different types of insulators used in overhead line construction?

- Pin Insulators: Used to support conductors on wooden poles.

- Suspension Insulators: Used to suspend conductors from towers or cross-arms.

- Polymer Insulators: Lightweight, non-ceramic insulators with excellent electrical properties.

- Glass Insulators: Traditional insulators with good dielectric strength but susceptible to breakage.

- Composite Insulators: Combine materials such as silicone rubber and fiberglass for superior performance in harsh conditions.

6. How do you identify and troubleshoot faults in overhead lines?

- Visual inspection for broken conductors, damaged insulators, or vegetation encroachment.

- Using test equipment such as meggers and fault locators to pinpoint the location of faults.

- Analyzing fault patterns and symptoms to determine the type of fault (e.g., short circuit, open circuit, ground fault).

- Consulting with engineers and experts to determine the best course of action for repair or replacement.

7. What are the different methods for installing overhead lines?

- Manual Installation: Using hand tools and crews to erect poles, string conductors, and install insulators.

- Aerial Installation: Using helicopters to lift and position poles and conductors in remote or difficult-to-reach areas.

- Horizontal Directional Drilling (HDD): Boring underground to install conduits for undergrounding lines.

- Underground Installation: Burying lines directly underground for increased reliability and aesthetics.

8. How do you handle emergency situations related to overhead lines?

- Immediately report the incident and evacuate the area.

- Contact the relevant authorities and emergency services.

- Secure the line and prevent further damage or injury.

- Coordinate with repair crews to restore power and make necessary repairs.

- Document the incident and communicate updates to stakeholders.

9. What is the importance of preventive maintenance for overhead lines?

- Extends the lifespan of lines and reduces the risk of failures.

- Improves reliability and reduces the likelihood of power outages.

- Prevents catastrophic events and ensures the safety of the public and infrastructure.

- Reduces the need for emergency repairs and associated costs.

- Optimizes line performance and efficiency.

10. How do you stay updated with the latest industry standards and best practices for overhead line construction and maintenance?

- Attend industry conferences and training programs.

- Read trade publications and technical journals.

- Consult with experts and engineers in the field.

- Stay informed about regulatory changes and safety guidelines.

- Network with peers and exchange knowledge and experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Line Out Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Line Out Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Line Out Workers are responsible for ensuring the smooth flow of production by monitoring and troubleshooting equipment, and taking corrective actions as needed. They are also responsible for maintaining the cleanliness and safety of their work area.

1. Monitor and troubleshoot equipment

Line Out Workers must be able to identify and troubleshoot problems with equipment, and take appropriate corrective actions. This may involve making adjustments to equipment settings, replacing parts, or calling for maintenance assistance.

- Monitor equipment for signs of trouble, such as unusual noises or vibrations.

- Identify and troubleshoot problems with equipment, and take appropriate corrective actions.

- Make adjustments to equipment settings, replace parts, or call for maintenance assistance as needed.

2. Maintain cleanliness and safety of the work area

Line Out Workers are responsible for keeping their work area clean and safe. This may involve sweeping up debris, mopping floors, and cleaning equipment. They must also be aware of potential hazards and take steps to prevent accidents.

- Sweep up debris and mop floors to keep the work area clean.

- Clean equipment to prevent contamination and ensure its proper functioning.

- Be aware of potential hazards and take steps to prevent accidents.

3. Other duties

In addition to the responsibilities listed above, Line Out Workers may also be responsible for:

- Assisting with maintenance and repair of equipment.

- Training new employees.

- Following safety procedures and wearing appropriate safety gear.

Interview Tips

To ace your interview for a Line Out Worker position, it is important to be prepared and to highlight your skills and experience. Here are a few tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the position.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read online reviews of the company to get a sense of its culture and work environment.

- Review the job description carefully to identify the key skills and experience required for the position.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Write down your answers to common interview questions and practice delivering them out loud.

- Ask a friend or family member to conduct a mock interview with you.

- Use the STAR method to answer interview questions. This method involves describing the Situation, Task, Action, and Result of a specific experience that demonstrates your skills and abilities.

3. Be prepared to talk about your experience and skills

In your interview, you will be asked to talk about your experience and skills. Be prepared to give specific examples of how you have used your skills to solve problems and achieve results. Be sure to highlight your experience in monitoring and troubleshooting equipment, as well as your ability to maintain a clean and safe work environment.

- Describe a time when you successfully troubleshooted a problem with equipment.

- Give an example of a time when you implemented a new safety procedure that improved the safety of your workplace.

- Explain how you would prioritize your tasks if you were working in a busy production environment.

4. Dress appropriately and arrive on time for your interview

First impressions matter, so it is important to dress appropriately for your interview. You should also arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Make sure to arrive for your interview on time. If you are running late, call or email the interviewer to let them know.

- Be polite and respectful to everyone you meet during your interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Line Out Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Line Out Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.