Are you gearing up for a career in Line Puller? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Line Puller and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

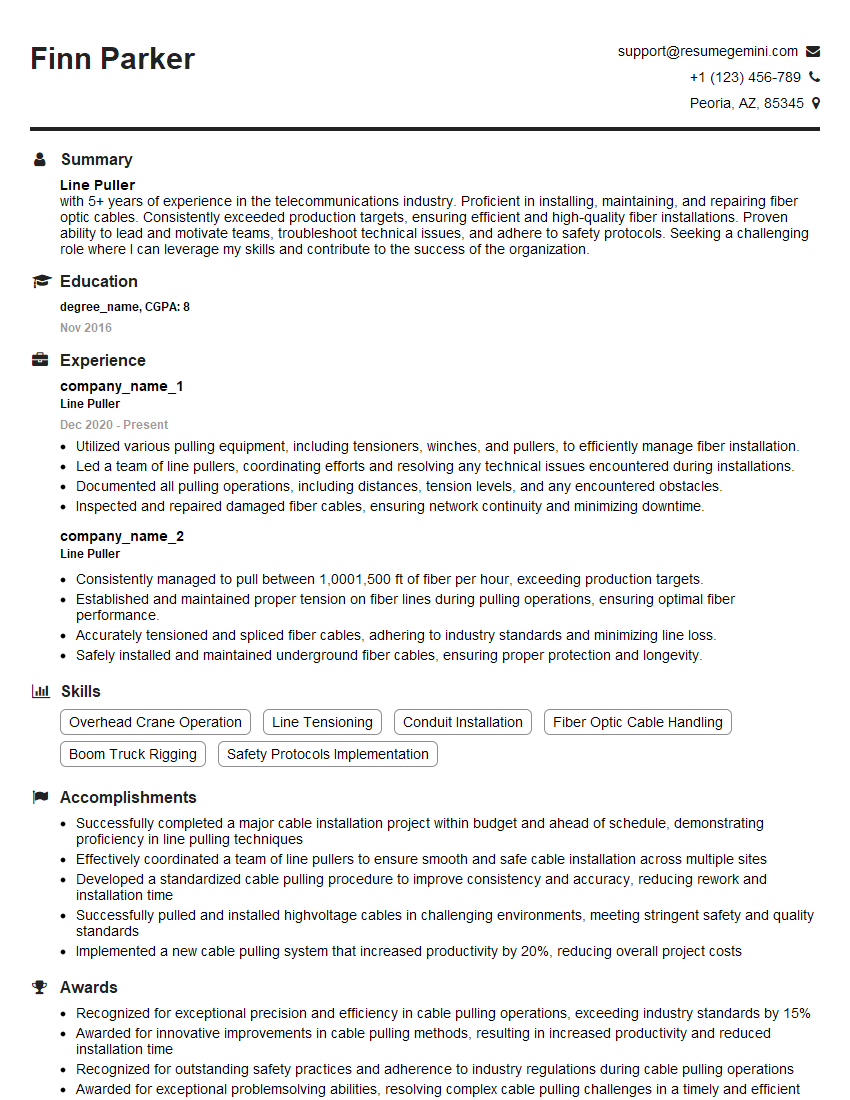

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Line Puller

1. What are the different types of line pulling equipment?

There are various types of line pulling equipment, including:

- Capstans: Used for pulling heavy loads over long distances

- Hydraulic winches: Powerful and compact, suitable for pulling in confined spaces

- Hand winches: Manual devices used for short pulls or light loads

- Tractors: Heavy-duty vehicles equipped with winches for pulling large loads

- Skidders: Forestry machines with winches for dragging logs

2. What are the key factors to consider when selecting line pulling equipment?

Load capacity

- Choose equipment with sufficient pulling force to handle the anticipated loads

Distance

- Consider the length of the pull and the equipment’s pulling speed

Terrain

- Choose equipment suitable for the terrain, such as rough or sloped surfaces

Cost

- Consider the equipment’s purchase or rental cost within the budget

3. Describe the proper techniques for handling and rigging lines.

Safe and proper line handling includes:

- Inspecting lines for damage before use

- Using gloves to protect hands from friction

- Avoiding wrapping lines around hands or clothing

- Ensuring lines are secure when rigged

- Using proper hitches and knots to prevent slipping

4. What are the potential hazards associated with line pulling and how can they be mitigated?

Hazards include:

- Cuts and abrasions from handling lines

- Electric shock from overhead power lines

- Crushing injuries from heavy equipment

- Tripping and falling

Mitigation measures include:

- Wearing appropriate PPE (gloves, hard hat, safety glasses)

- Maintaining a safe work zone

- Following proper line handling and rigging techniques

- Being aware of potential hazards and taking precautions

5. How do you ensure the safe operation of line pulling equipment?

Ensuring safety requires:

- Regular maintenance and inspections of equipment

- Training operators on proper use

- Establishing clear operating procedures

- Using appropriate safety devices such as tensioning straps

- Monitoring weather conditions and adjusting operations as needed

6. What are the different methods of attaching lines to loads?

Methods include:

- Direct connection: Using hooks, shackles, or eyebolts

- Soft sling: Using synthetic or fiber slings

- Chain sling: Using steel chains

- Choker hitch: Using a loop of cable or chain around the load

- Basket hitch: Using multiple lines to create a cradle for the load

7. How do you troubleshoot common line pulling problems?

Common problems and troubleshooting steps include:

- Line slipping: Check for proper rigging, damaged lines, or excessive load

- Equipment overheating: Ensure proper lubrication, inspect for blockages, and allow for cooling

- Load not moving: Verify the equipment is powerful enough, inspect for obstructions, or adjust the pulling angle

- Line breakage: Examine lines for damage, overload, or improper handling

- Equipment failure: Check for loose connections, electrical faults, or hydraulic leaks

8. What are the best practices for communicating with team members during line pulling operations?

Effective communication involves:

- Using clear and concise language

- Establishing hand signals or verbal cues

- Maintaining eye contact and being aware of body language

- Providing timely updates and requesting feedback

- Listening actively and responding appropriately

9. How do you handle emergency situations during line pulling operations?

Emergency procedures include:

- Assessing the situation and ensuring safety

- Alerting supervisors and emergency responders

- Isolating the equipment and disconnecting power sources

- Providing first aid if necessary

- Investigating the cause of the emergency and taking corrective actions

10. What additional skills and knowledge are beneficial for a Line Puller?

Valuable skills include:

- Knot tying and splicing techniques

- Basic mechanics and equipment repair

- Understanding of load capacities and rigging safety

- Physical strength and endurance

- Attention to detail and ability to follow instructions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Line Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Line Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Line Puller plays a crucial role in electrical construction and maintenance projects. Their primary responsibility involves pulling electrical wires and cables through conduits and other pathways to connect electrical components and systems.

1. Wire and Cable Handling

Line Pullers are proficient in handling various types of electrical wires and cables. They ensure that the wires are not damaged or tangled during the pulling process.

- Select and prepare wires and cables based on the project specifications.

- Uncoil, straighten, and feed wires through conduits and other pathways.

2. Equipment Operation

Line Pullers operate specialized equipment such as pulling machines, tensioners, and winches to facilitate wire and cable pulling.

- Set up and operate pulling machinery to pull wires and cables through conduits.

- Adjust tension to prevent damage to wires and ensure proper installation.

3. Conduit and Raceway Installation

Line Pullers collaborate with other electricians to install conduits and raceways that house the electrical wires.

- Lay out and install conduits and raceways according to the electrical plans.

- Secure conduits and raceways using fasteners and supports.

4. Troubleshooting and Repairs

Line Pullers identify and resolve issues related to wire pulling and conduit installation.

- Troubleshoot pulling difficulties, such as blockages or tangled wires.

- Repair or replace damaged wires, conduits, or raceways.

Interview Tips

Preparing thoroughly for a Line Puller interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Know the Job Description

Familiarize yourself with the key job responsibilities and requirements outlined in the job description. This will help you tailor your answers to the specific needs of the role.

- Highlight your experience in wire and cable handling, equipment operation, and conduit installation.

- Quantify your accomplishments and provide specific examples to demonstrate your skills and abilities.

2. Research the Company

Learn about the company’s history, values, and current projects. This knowledge will show the interviewer that you are genuinely interested in the position and the company.

- Visit the company’s website and social media pages.

- Read industry publications and news articles to stay informed about the company’s activities.

3. Practice Your Answers

Prepare thoughtful responses to common interview questions. Practice answering them out loud to improve your delivery and confidence.

- Anticipate questions related to your experience, skills, and why you are interested in the role.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide clear examples.

4. Dress Professionally

Make a good first impression by dressing appropriately for the interview. Business casual attire is typically recommended, but always check the company’s dress code policy.

- Choose clean, ironed clothing that fits well.

- Avoid wearing overly casual or revealing clothing.

5. Be Enthusiastic and Confident

Project a positive attitude and enthusiasm for the role. Confidence is contagious, and it can make a significant impact on the interviewer’s perception of you.

- Smile, make eye contact, and speak clearly.

- Be prepared to share your accomplishments and express your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Line Puller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.