Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Liner Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

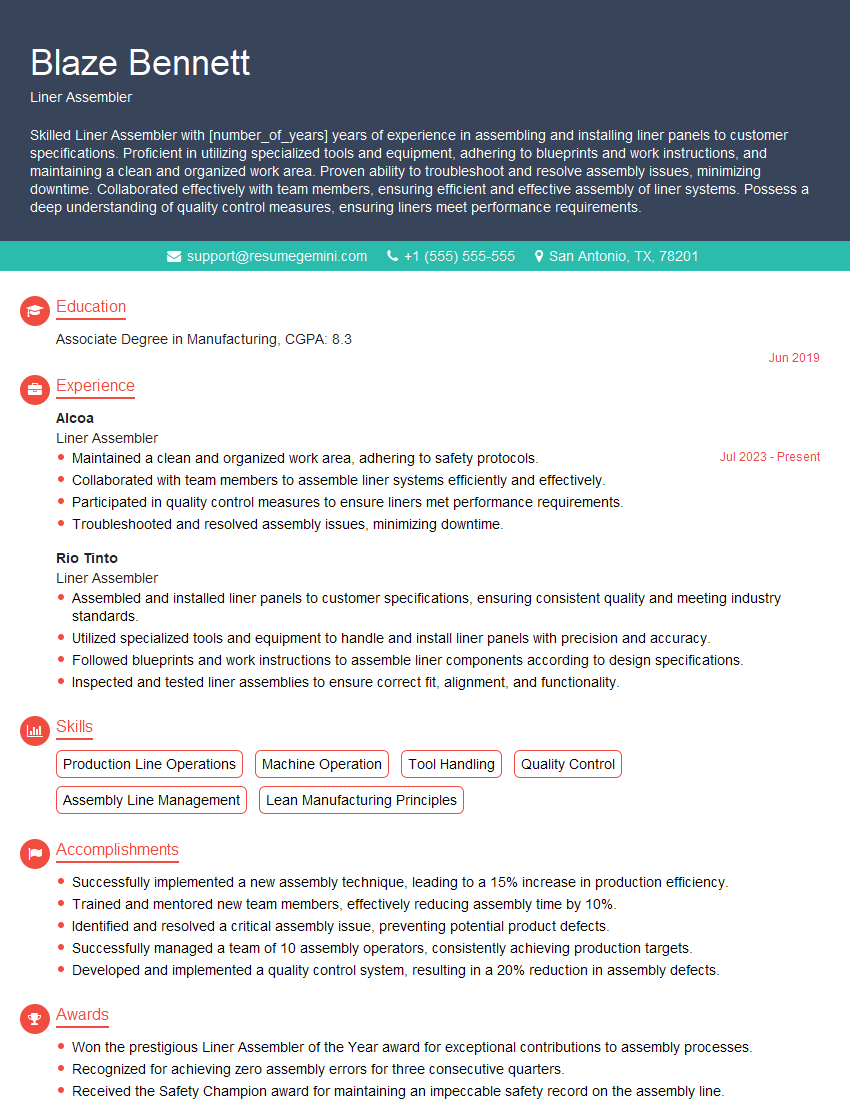

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liner Assembler

1. What are the different types of liners used in the liner assembly process?

There are several types of liners used in the liner assembly process, including:

- Polyethylene (PE) liners

- Polypropylene (PP) liners

- Polyvinyl chloride (PVC) liners

- Ethylene copolymer (EC) liners

- Fluorinated ethylene propylene (FEP) liners

2. What are the key factors that influence the selection of a specific liner material?

Material properties

- Chemical compatibility

- Corrosion resistance

- Temperature resistance

- Mechanical strength

Project requirements

- Liner size and shape

- Operating environment

- Expected lifespan

- Cost

3. Describe the process of installing a liner in a landfill.

The process of installing a liner in a landfill typically involves the following steps:

- Preparing the subgrade by leveling and compacting the soil

- Installing a geotextile layer to protect the liner from punctures

- Unrolling and positioning the liner material

- Welding or seaming the liner seams to ensure a watertight seal

- Covering the liner with a protective layer of soil or geotextile

4. What are the different methods of liner seaming?

- Hot air welding

- Extrusion welding

- Solvent welding

- Chemical bonding

- Mechanical seaming

5. What is the importance of quality control in liner assembly?

- Ensuring a watertight seal to prevent leakage

- Minimizing the risk of liner failure

- Maintaining the integrity of the landfill system

- Meeting regulatory requirements

6. Describe the different types of liner testing methods.

- Nondestructive testing (NDT):

- Spark testing

- Vacuum testing

- Ultrasonic testing

- Radiographic testing

- Destructive testing:

- Tensile testing

- Tear testing

- Puncture testing

7. What are the common defects that can occur during liner assembly?

- Holes or tears in the liner material

- Improperly welded or seamed seams

- Inadequate compaction of the subgrade

- Presence of foreign objects in the liner system

- Damage caused by weather or heavy equipment

8. What are the safety precautions that should be taken when working with liner materials?

- Wearing appropriate protective clothing and equipment

- Properly handling and storing liner materials

- Following established safety procedures

- Working with a qualified supervisor

- Being aware of potential hazards, such as chemical fumes and hot equipment

9. What is the role of geosynthetics in liner assembly?

- Providing a protective layer between the liner and the subgrade

- Preventing punctures and tears in the liner material

- Improving the drainage properties of the landfill system

- Increasing the overall stability of the liner system

10. What are the future trends in liner assembly technology?

- Development of new liner materials with improved performance properties

- Increased use of automated and robotic systems for liner installation

- Integration of advanced sensing and monitoring technologies for real-time liner performance monitoring

- Focus on sustainable and environmentally friendly liner assembly practices

- Continued research and development to enhance the effectiveness and efficiency of liner assembly systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liner Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liner Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Liner Assemblers play a crucial role in manufacturing, responsible for assembling and installing linings within equipment, containers, and structures.

1. Linings Installation and Assembly

Installing and assembling liners made of various materials (e.g., rubber, plastic, fabric) to specified dimensions and tolerances.

- Adhering to blueprints and specifications for accurate liner placement.

- Operating specialized equipment like glue spreaders, rollers, and heat sealing machines.

2. Verification and Quality Control

Inspecting installed liners for defects, ensuring they meet quality standards.

- Conducting visual inspections, leak tests, and other quality control measures.

- Maintaining detailed records of liner installation and inspection results.

3. Equipment Maintenance

Maintaining and calibrating equipment used in liner assembly, ensuring optimal performance.

- Cleaning, lubricating, and adjusting machines regularly.

- Performing minor repairs and troubleshooting equipment issues.

4. Safety and Compliance

Adhering to safety regulations and industry standards, ensuring a safe work environment.

- Wearing proper protective gear and following safety protocols.

- Handling and storing hazardous materials safely.

Interview Tips

To ace a Liner Assembler interview, it’s important to prepare effectively and present yourself confidently.

1. Research the Company and Industry

Research the company’s history, products, and industry trends to demonstrate your interest and understanding of the field.

- Visit the company website and read industry publications.

- Identify the company’s competitors and their market share.

2. Practice Your Answers

Prepare your responses to common interview questions related to your skills, experience, and motivations.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and highlight your accomplishments.

- Quantify your achievements whenever possible, using specific numbers and metrics.

3. Showcase Your Expertise

Highlight your technical skills and knowledge of liner assembly processes and materials.

- Discuss your experience with different types of liners and applications.

- Explain your understanding of quality control standards and inspection techniques.

4. Emphasize Safety and Attention to Detail

Emphasize your commitment to safety and your attention to detail.

- Describe your experience with safety regulations and hazard identification.

- Highlight your ability to follow precise instructions and maintain high accuracy levels.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Liner Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!