Are you gearing up for an interview for a Liner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Liner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

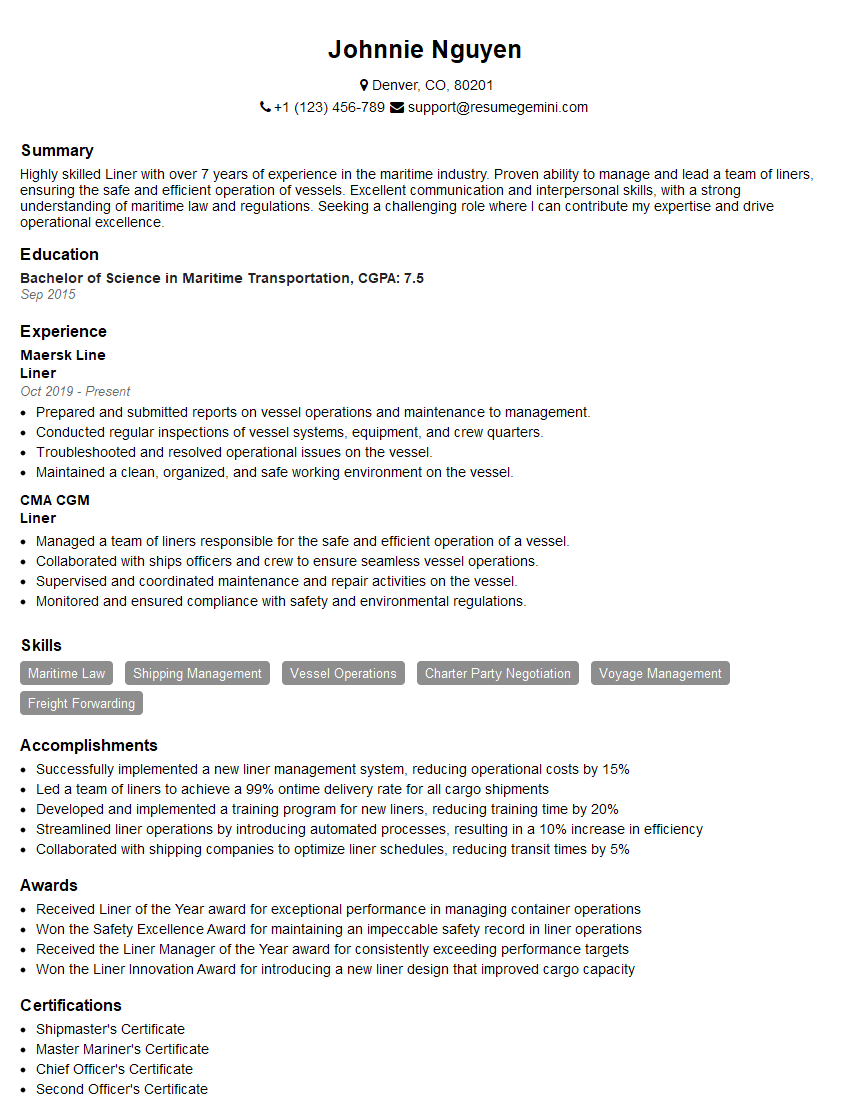

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liner

1. Discuss the different types of liner machines and their uses?

- Coil liners: These are the most common type of liner machines and are used for a variety of purposes, including outlining, shading, and filling. They are known for their precision and control.

- Rotary liners: These machines are newer than coil liners and are becoming increasingly popular. They are known for their smooth, consistent lines and are ideal for delicate work.

- Pneumatic liners: These machines use compressed air to power the needles, which results in a very smooth, consistent line. They are often used for fine detail work.

2. What are the different needle configurations used for lining?

Round liners

- These are the most common type of needle configuration and are used for a variety of purposes, including outlining, shading, and filling.

- They are available in a variety of sizes, from 1 to 18, with larger numbers indicating a thicker needle.

Tight liners

- These are similar to round liners, but they are spaced closer together, which results in a thinner, more precise line.

- They are often used for delicate work, such as facial features or fine details.

Magnum liners

- These are made up of multiple needles that are soldered together in a row.

- They are used for creating bold, thick lines and are often used for lettering or tribal designs.

3. What are the different techniques used for lining?

- Hand lining: This is the most traditional method of lining and involves holding the machine in your hand and guiding it along the skin.

- Machine lining: This method uses a machine to power the needles, which results in more consistent and precise lines.

- Freehand lining: This method involves holding the machine in your hand and moving it freely along the skin, without using a guide.

4. What are the different factors that affect the quality of a line?

- Needle size: The size of the needle will affect the thickness of the line.

- Needle spacing: The spacing of the needles will affect the precision of the line.

- Machine settings: The voltage and speed of the machine will affect the smoothness and consistency of the line.

- Artist’s technique: The artist’s skill and experience will also play a role in the quality of the line.

5. What are some tips for getting good at lining?

- Practice regularly: The more you practice, the better you will become at lining.

- Use the right tools: Make sure you are using the right machine, needles, and ink for the job.

- Be patient: Don’t try to rush the process. Take your time and focus on getting the lines right.

- Get feedback: Ask other artists for feedback on your work and take their advice into consideration.

6. What are some of the common mistakes that beginners make when lining?

- Using the wrong needle size or spacing: This can result in lines that are too thick, too thin, or too imprecise.

- Using the wrong machine settings: This can result in lines that are too shaky, too slow, or too fast.

- Not holding the machine steady: This can result in lines that are uneven or wobbly.

- Not taking your time: Rushing the process can lead to mistakes.

7. What are some of the advanced techniques that you use for lining?

8. What are some of the challenges that you face when lining?

- Getting the line straight: This can be difficult, especially on curved surfaces.

- Getting the line even: This can be difficult, especially if you are using a hand machine.

- Getting the line the right thickness: This can be difficult, especially if you are using different needle sizes.

9. What are some of the ways that you overcome these challenges?

- Using a guide: This can help you to get the line straight.

- Using a machine with a built-in stabilizer: This can help you to get the line even.

- Using different needle sizes: This can help you to get the line the right thickness.

10. What are some of the new techniques or technologies that you are interested in learning for lining?

- 3D printing: This technology can be used to create custom-designed stencils for lining.

- Laser engraving: This technology can be used to create precise and intricate lines.

- Artificial intelligence: This technology can be used to develop software that can assist artists with lining.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Liner, your primary responsibility is to install and maintain liners in various applications. Liners are used to prevent leaks, protect surfaces, and contain materials in a wide range of industries.

1. Installation and Maintenance of Liners

You will be responsible for installing and maintaining liners in various applications, including:

- Industrial tanks and vessels

- Wastewater treatment facilities

- Mining and agricultural operations

- Transportation and storage containers

2. Materials and Equipment Knowledge

You will have a comprehensive understanding of different liner materials and their properties, such as:

- Polyvinyl chloride (PVC)

- Polyethylene (PE)

- Polypropylene (PP)

- Fiberglass-reinforced plastic (FRP)

3. Inspection and Repair

You will regularly inspect liners for damage and wear. When necessary, you will repair or replace damaged sections to ensure proper functionality and prevent leaks.

4. Communication and Safety

You will work closely with other members of the maintenance team and communicate with clients to ensure that all liner installations and maintenance meet specifications. You will also follow all safety protocols and regulations to prevent accidents.

Interview Tips

Preparing thoroughly for your liner interview is crucial to making a positive impression and demonstrating your qualifications.

1. Research the company and position

Visit the company’s website to learn about their business, services, and values. Read the job description carefully to understand the specific responsibilities and requirements of the position.

- Research the company’s competitors and the industry to demonstrate your understanding of the market.

- Prepare questions about the company’s plans for the future and how the role contributes to their success.

2. Highlight your relevant skills and experience

Review the job description and identify the key skills and experience required. Tailor your resume and cover letter to highlight your relevant qualifications.

- Quantify your accomplishments whenever possible, using specific examples and metrics to demonstrate your impact.

- Prepare to discuss your experience in installing and maintaining liners, working with different materials and equipment, and ensuring compliance with safety regulations.

3. Practice your answers to common interview questions

Research common interview questions and prepare your answers in advance. This will help you feel more confident and articulate during the interview.

- Common interview questions for a liner may include:

- Tell me about your experience in installing and maintaining liners.

- What are your strengths and weaknesses as a liner?

- How do you stay up-to-date on the latest industry trends and technologies?

- Prepare your own questions to ask the interviewer to show your interest and enthusiasm for the role.

4. Dress professionally and arrive promptly

First impressions matter, so make sure to dress professionally and arrive on time for your interview. This demonstrates respect for the interviewer’s time and sends a positive message about your work ethic.

- Choose attire that is appropriate for the company culture and industry.

- Be punctual and allow extra time for potential delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Liner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!