Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Liner Reroll Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

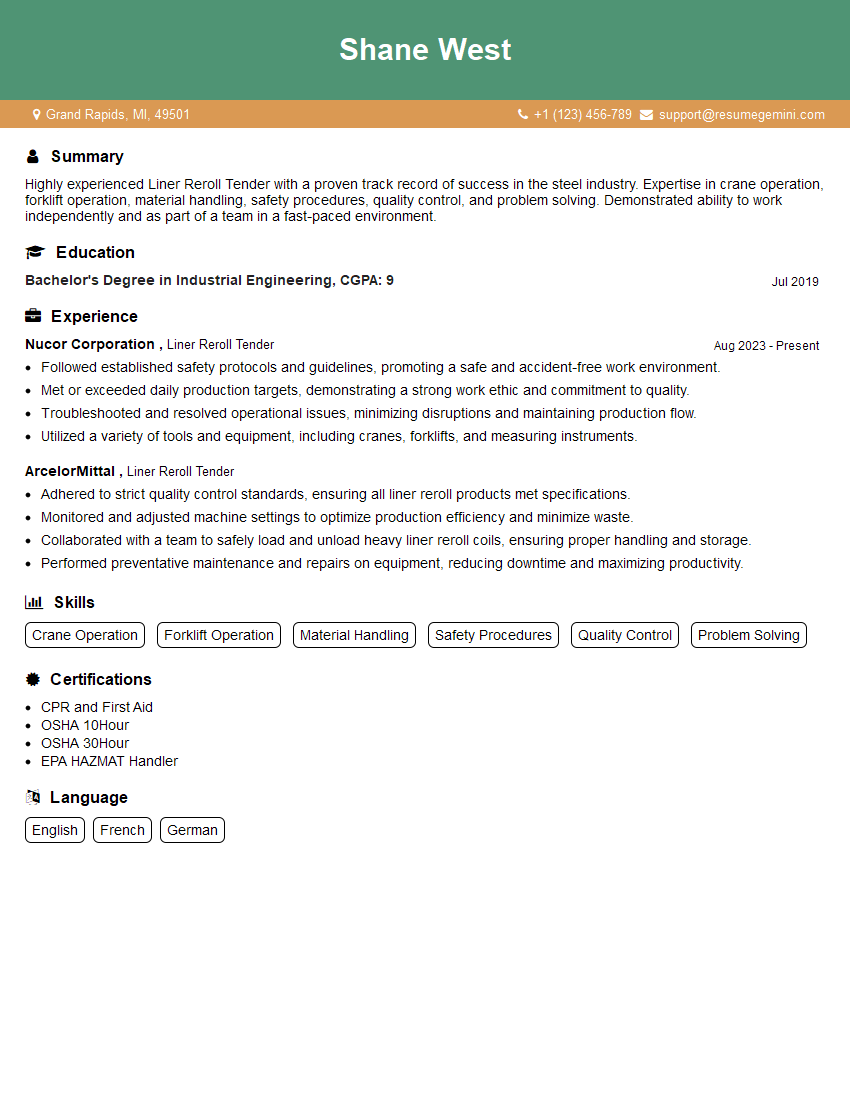

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liner Reroll Tender

1. Explain the process of liner rerolling?

The process of liner rerolling involves taking a used liner, which is typically made of steel or other metal, and reprocessing it into a new liner. This process is typically carried out by a liner rerolling mill, which uses a series of rollers to flatten and reshape the used liner. The resulting product is a new liner that can be used in a variety of applications, such as in the construction of buildings and bridges.

- The first step in the liner rerolling process is to inspect the used liner and remove any contaminants, such as dirt or grease.

- The liner is then passed through a series of rollers, which flatten and reshape it.

- The liner is then annealed, which is a process of heating and cooling the metal to make it more pliable and easier to work with.

- The liner is then passed through a series of finishing rollers, which give it its final shape and dimensions.

- The liner is then inspected and tested to ensure that it meets the required specifications.

2. What are the different types of liners that can be rerolled?

Cold-rolled liners

- Cold-rolled liners are made by passing steel through a series of rollers at room temperature.

- This process makes the steel harder and stronger than hot-rolled liners.

- Cold-rolled liners are typically used in applications where strength and durability are important, such as in the construction of buildings and bridges.

Hot-rolled liners

- Hot-rolled liners are made by passing steel through a series of rollers at high temperatures.

- This process makes the steel softer and more pliable than cold-rolled liners.

- Hot-rolled liners are typically used in applications where formability and ductility are important, such as in the manufacture of car bodies and appliances.

Galvanized liners

- Galvanized liners are made by coating steel with a layer of zinc.

- This coating protects the steel from corrosion and rust.

- Galvanized liners are typically used in applications where corrosion resistance is important, such as in the construction of roofing and siding.

3. What are the advantages of using rerolled liners?

- Rerolled liners are more cost-effective than new liners.

- Rerolled liners are more environmentally friendly than new liners, as they use less energy and resources to produce.

- Rerolled liners are just as strong and durable as new liners.

4. What are the applications of rerolled liners?

- Rerolled liners are used in a variety of applications, including:

- Construction

- Automotive

- Appliance

- Packaging

5. What are the challenges of liner rerolling?

- The main challenge of liner rerolling is to ensure that the rerolled liner meets the required specifications.

- This can be difficult to achieve, as the rerolling process can introduce defects into the liner.

- Another challenge of liner rerolling is to minimize the cost of the process.

- This can be difficult to achieve, as the rerolling process requires a significant amount of energy and resources.

6. What are the latest trends in liner rerolling?

- The latest trends in liner rerolling include:

- The use of new technologies to improve the quality and efficiency of the rerolling process.

- The development of new liner materials that are more suited to rerolling.

- The increasing use of rerolled liners in a variety of applications.

7. What is the future of liner rerolling?

- The future of liner rerolling is bright.

- As the demand for steel continues to grow, the demand for rerolled liners is also expected to grow.

- The development of new technologies and materials is expected to make liner rerolling even more cost-effective and environmentally friendly.

8. What are the skills and qualifications required for a Liner Reroll Tender?

- A Liner Reroll Tender must have a strong understanding of the liner rerolling process.

- They must also have experience in the steel industry.

- Additionally, Liner Reroll Tenders must have excellent communication and interpersonal skills.

9. What are the responsibilities of a Liner Reroll Tender?

- The responsibilities of a Liner Reroll Tender include:

- Managing the liner rerolling process

- Ensuring that the rerolled liners meet the required specifications

- Minimizing the cost of the rerolling process

- Keeping up-to-date on the latest trends in liner rerolling

10. What are the career prospects for a Liner Reroll Tender?

- The career prospects for a Liner Reroll Tender are good.

- As the demand for steel continues to grow, the demand for Liner Reroll Tenders is also expected to grow.

- Liner Reroll Tenders with experience and expertise can advance to management positions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liner Reroll Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liner Reroll Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Liner Reroll Tender is a crucial position within a steel manufacturing plant, responsible for ensuring the smooth and efficient operation of the liner reroll process. The key job responsibilities encompass:

1. Operation of Liner Reroll Machine

Setting up, operating, and monitoring the liner reroll machine

- Loading and unloading coils

- Adjusting machine settings for optimal performance

2. Quality Control

Inspecting and measuring coils to ensure they meet specifications

- Identifying and resolving quality defects

- Maintaining quality records and reports

3. Production Monitoring

Monitoring production output and identifying potential bottlenecks

- Making adjustments to improve efficiency

- Reporting production data to supervisors

4. Maintenance and Troubleshooting

Performing basic maintenance and troubleshooting on the liner reroll machine

- Identifying and resolving mechanical or electrical issues

- Requesting assistance from maintenance personnel for complex repairs

Interview Tips

To effectively ace the interview for a Liner Reroll Tender position, it is vital to:

1. Research the Company and Industry

Delve into the company’s website, LinkedIn page, and industry news to understand their business, products, and recent developments.

- This demonstrates your genuine interest and commitment to the role.

- It helps you tailor your answers to align with the company’s specific requirements.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience and technical skills in operating liner reroll machines and performing quality control.

- Provide concrete examples to showcase your abilities and quantify your accomplishments.

- If you have previous experience in a similar role, highlight transferable skills.

3. Demonstrate Safety Awareness

Liner Reroll Tenders play a crucial role in maintaining a safe work environment.

- Emphasize your commitment to following safety protocols and procedures.

- Share examples of how you have proactively identified and addressed potential safety hazards.

4. Prepare for Technical Questions

Be ready to answer technical questions about the liner reroll process, machine operation, and quality control techniques.

- Review technical specifications and industry best practices.

- Consider preparing sample answers to common technical questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Liner Reroll Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.