Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lining Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

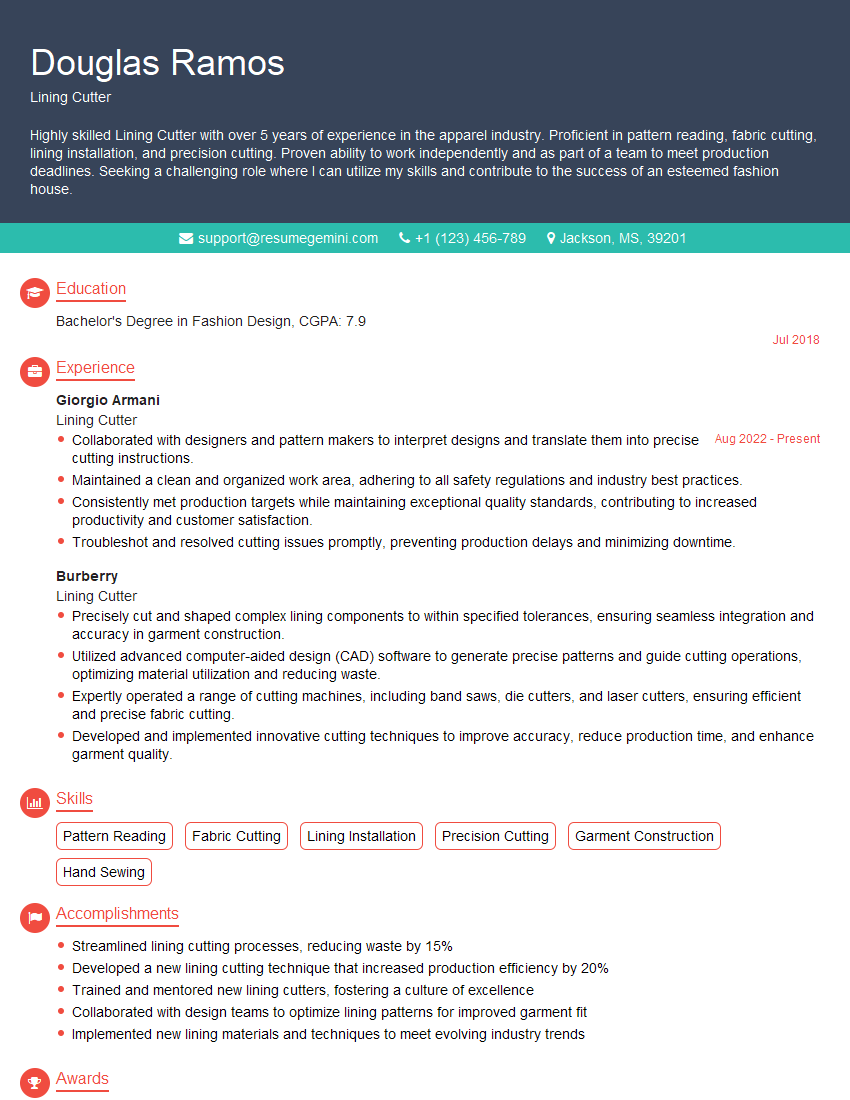

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lining Cutter

1. What are the primary responsibilities of a Lining Cutter?

As a Lining Cutter, my key responsibilities include:

- Cutting and shaping lining materials according to specifications

- Measuring, marking, and aligning lining materials

- Ensuring accuracy and quality of cut linings

- Maintaining a clean and organized work area

- Collaborating with production team to meet deadlines

2. Describe the process of cutting and shaping lining materials.

Planning and Measurement:

- Review cutting instructions and specifications

- Measure and mark lining materials precisely

Cutting:

- Select appropriate cutting tools

- Cut lining materials using precision techniques

- Ensure smooth and accurate cuts

Shaping:

- Follow patterns to shape lining materials

- Use bending, forming, and pressing techniques

- Achieve desired shape and fit

3. What are the different types of lining materials used in shoemaking?

Common lining materials used in shoemaking include:

- Leather: Durable, breathable, and luxurious

- Fabric: Wide range of options, including mesh, canvas, and silk

- Synthetics: Moisture-resistant, lightweight, and affordable

- Foam: Cushioning and insulating properties

- Cork: Natural, breathable, and moisture-absorbent

4. How do you ensure the accuracy and quality of cut linings?

To ensure accuracy and quality, I follow these steps:

- Precise measuring and marking

- Using sharp and well-maintained cutting tools

- Careful alignment and cutting techniques

- Regular inspection and checking of cut linings

- Adhering to established quality standards

5. What is the importance of maintaining a clean and organized work area in lining cutting?

A clean and organized work area is crucial for:

- Safety: Prevents accidents and injuries

- Accuracy: Reduces errors and ensures precision

- Efficiency: Streamlines workflow and reduces downtime

- Material preservation: Prevents damage or contamination

- Professionalism: Projects a positive and organized image

6. Describe your experience in working with different types of shoe lasts.

I have experience working with a variety of shoe lasts, including:

- Dress lasts: Formal and elegant designs

- Athletic lasts: Performance-oriented and comfortable

- Casual lasts: Versatile and suitable for everyday wear

- Custom lasts: Tailored to individual foot shapes

- Specialty lasts: Designed for specific purposes, such as work boots or dance shoes

7. How do you handle and resolve any issues that may arise during lining cutting?

When issues arise, I follow these steps:

- Identify the problem and its potential causes

- Consult with supervisors or colleagues for guidance

- Explore and implement solutions to rectify the issue

- Document the problem and resolution for future reference

- Continuously improve processes to minimize future occurrences

8. Can you explain the concept of “run-off” in lining cutting and its significance?

Run-off refers to the additional material added to a lining piece to ensure proper fitting and alignment.

- Compensates for stretch and shrinkage during production

- Ensures a snug and secure fit

- Prevents gaps or excess material in the lining

- Determines the overall quality and appearance of the footwear

9. What are the safety precautions you observe while operating lining cutting equipment?

To ensure safety, I adhere to the following precautions:

- Wear proper personal protective equipment (PPE)

- Maintain a clean and clear work area

- Inspect equipment regularly and report any issues

- Follow established safety protocols and procedures

- Remain focused and avoid distractions

10. How do you stay up-to-date with the latest techniques and advancements in lining cutting?

To stay current, I engage in the following activities:

- Attend industry workshops and seminars

- Read trade publications and technical articles

- Network with other professionals in the field

- Explore new materials and technologies

- Receive training from experienced colleagues

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lining Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lining Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lining Cutters are responsible for cutting and shaping lining materials used in the production of garments, footwear, and other sewn products. Their primary duties involve:

1. Lining Cutting

Using sharp knives or cutting machines, Lining Cutters meticulously cut lining fabrics according to specified patterns and templates.

- Analyze garment designs and patterns to determine lining requirements.

- Select and prepare lining materials, ensuring they meet quality standards.

- Operate cutting machines or use hand-held knives to cut lining pieces with precision.

- Inspect cut lining pieces for accuracy, ensuring they meet specifications.

2. Quality Control

Lining Cutters play a crucial role in maintaining quality standards by:

- Adhering to established cutting guidelines and specifications.

- Inspecting lining pieces for defects, ensuring they meet quality requirements.

- Identifying and correcting errors in cutting patterns.

- Providing feedback to improve cutting processes and materials.

3. Material Handling

Efficient material handling is essential for Lining Cutters. They:

- Unload and store incoming lining materials, maximizing space utilization.

- Organize and maintain cutting areas, ensuring a clean and efficient work environment.

- Dispose of waste materials in a responsible and environmentally friendly manner.

4. Teamwork and Communication

Lining Cutters often collaborate with other members of the production team, including:

- Working closely with pattern makers to ensure accurate cutting.

- Communicating with supervisors and colleagues to resolve issues and improve productivity.

- Participating in training sessions to enhance skills and knowledge.

Interview Tips

To ace a Lining Cutter interview, candidates should:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the garment or footwear industry. Research their products, history, and key competitors.

- Visit the company’s website and read industry publications.

- Connect with employees on LinkedIn to gain insights into the company culture.

2. Prepare Examples of Your Work

Showcase your lining cutting skills by bringing examples of your work. This could include portfolio samples or photos of your previous projects.

- Highlight your attention to detail and precision in cutting.

- Explain the challenges you faced and how you overcame them.

3. Practice Your Skills

Before the interview, practice your lining cutting skills. This will help you demonstrate your proficiency and confidence during the interview.

- Set up a cutting area and practice cutting different types of lining fabrics.

- Use different cutting tools and techniques to improve your dexterity.

4. Prepare for Common Interview Questions

Research common Lining Cutter interview questions and prepare your answers. This will help you stay calm and focused during the interview.

- Tell me about your experience in lining cutting.

- Describe a project where you demonstrated your precision and attention to detail.

- How do you handle mistakes in cutting?

5. Ask Insightful Questions

Prepare a few thoughtful questions to ask the interviewer. This shows your interest in the position and the company.

- What are the key challenges facing the lining cutting department?

- What opportunities for professional development are available?

- How do you measure success in this role?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lining Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.