Are you gearing up for a career in Lining Layer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lining Layer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

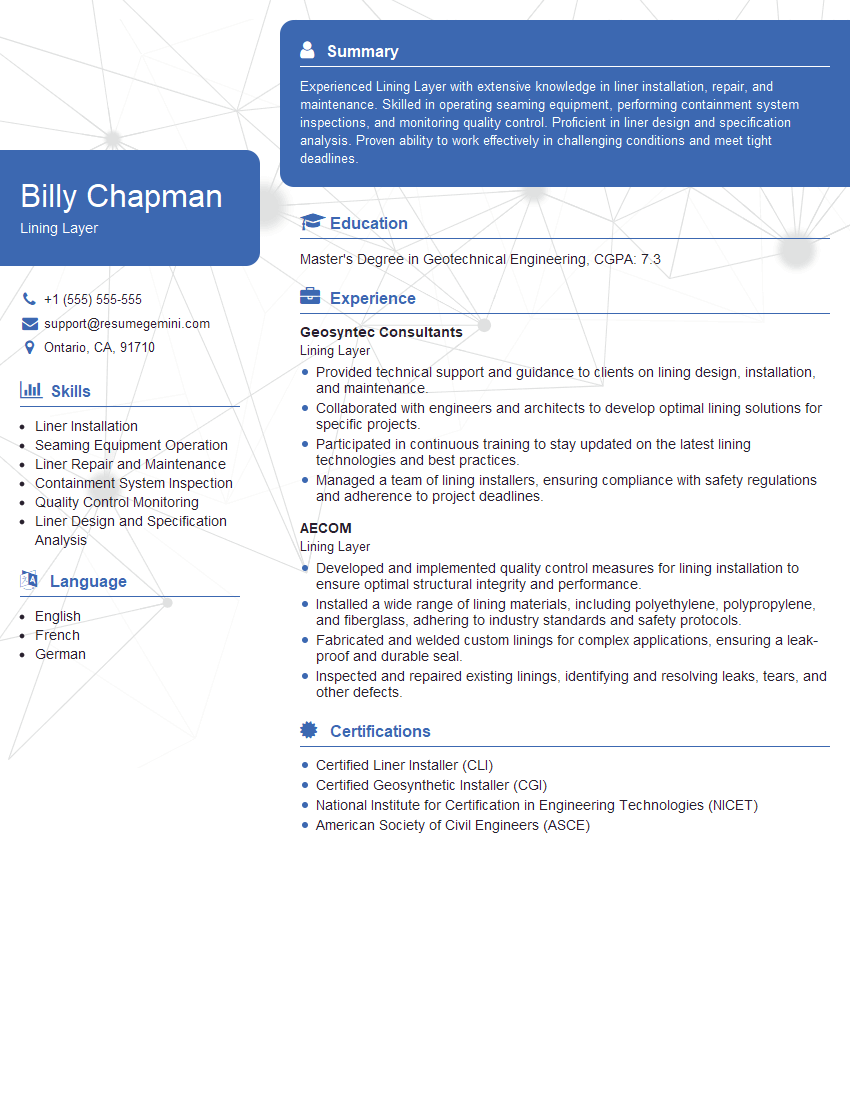

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lining Layer

1. What are the essential tools and materials required for Lining Layer?

- Shovel and rake for excavation and backfilling

- Tamping tool for compacting soil

- Level and string line for ensuring lining alignment

- Lining material (e.g., geosynthetic liner, soil-bentonite liner)

- Protective layer material (e.g., geotextile, crushed stone)

2. How do you determine the required thickness of a lining system?

Considering Soil Properties

- Evaluate soil type, permeability, and compaction characteristics

- Estimate hydraulic head and seepage rates

Following Regulations and Standards

- Refer to applicable regulations and industry standards

- Consider the specific design requirements and environmental conditions

3. Describe the steps involved in installing a geosynthetic liner.

- Prepare the subgrade by excavating and compacting

- Lay out and unfurl the liner material smoothly

- Weld or bond the seams according to manufacturer’s specifications

- Protect the liner with a geotextile or other protective layer

- Anchor the liner around the perimeter and any penetrations

4. How do you handle wrinkles and folds in a lining material?

- Gently smooth out the wrinkles by pulling or rolling

- If excessive, cut and re-weld or bond the affected area

- Avoid overstretching the liner, as it can weaken the material

5. What are the most common defects associated with lining installations?

- Seam failure due to improper welding or bonding

- Tearing or puncturing from handling or sharp objects

- Wrinkling or folding that can compromise the integrity of the lining

- Inadequate anchoring, allowing the lining to shift or move

6. How do you ensure quality control during lining installation?

- Follow a detailed installation plan and specifications

- Inspect materials and equipment before use

- Supervise and monitor the installation process

- Conduct non-destructive testing (e.g., spark testing, vacuum box testing)

- Document the installation process and test results

7. What are the environmental considerations for lining installation?

- Minimize soil disturbance and erosion during excavation

- Properly dispose of excavated materials and construction waste

- Protect water resources from contamination

- Adhere to environmental regulations and best practices

8. How do you calculate the volume of materials required for a lining installation?

- Determine the area to be lined

- Estimate the thickness of the lining material

- Multiply the area by the thickness to get the volume

- Include additional materials for overlaps, anchors, and protective layers

9. Describe the different types of lining materials and their applications.

- Geosynthetic liners: Durable, flexible materials used for various containment applications

- Soil-bentonite liners: Bentonite-infused soil that swells when hydrated, creating a low-permeability barrier

- Asphalt liners: Hot-applied bituminous materials used for waterproofing and protection

- Concrete liners: Durable, rigid materials offering high strength and resistance

10. How do you prepare a subgrade for lining installation?

- Excavate to the required depth and shape

- Remove any vegetation, debris, or irregularities

- Compact the soil to achieve the specified density

- Slope or grade the subgrade to ensure proper drainage

- Protect the subgrade from moisture and erosion

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lining Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lining Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lining Layers are employed in the mining industry to supervise and install the lining within the mine shafts. They are tasked with ensuring that the lining is properly installed and maintained, to prevent accidents and injuries to miners and protect the mine’s structure. Their key job responsibilities include:

1. Installation and Maintenance of Lining

The primary responsibility of Lining Layers is to install and maintain the lining within the mine shafts. This involves:

- Inspecting the mine shaft and determining the type of lining required

- Installing the lining according to the approved plans and specifications

- Repairing and replacing damaged lining as necessary

- Ensuring that the lining is properly secured and sealed to prevent water leakage and other hazards

2. Supervision of Lining Installation

Lining Layers may also be responsible for supervising the installation of the lining. This involves:

- Providing guidance and instruction to other workers involved in the installation process

- Ensuring that all workers are following the approved plans and specifications

- Inspecting the completed installation to ensure that it meets the required standards

3. Safety and Compliance

Safety is paramount for Lining Layers, and they are responsible for:

- Complying with all applicable safety regulations and procedures

- Using personal protective equipment (PPE) and ensuring that other workers do the same

- Identifying and reporting potential hazards to supervisors

- Participating in safety training and drills

4. Communication and Documentation

Lining Layers must be able to effectively communicate with supervisors, other workers, and contractors. They are also responsible for:

- Maintaining accurate records of the lining installation and maintenance activities

- Preparing reports and summaries as required by supervisors or management

Interview Tips

Preparing for a Lining Layer interview can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before the interview, take the time to research the mining company and the specific position you are applying for. This will help you better understand the company’s culture, values, and the specific responsibilities of the role. You can find this information on the company’s website, social media pages, or by reading industry news and articles.

2. Practice Your Answers to Common Interview Questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?”. Practice your answers to these questions in advance so that you can deliver them confidently and concisely during the interview.

3. Highlight Your Relevant Skills and Experience

Be sure to highlight your relevant skills and experience during the interview. This includes any experience you have in installing or maintaining lining in mine shafts, as well as any other relevant skills such as safety training, communication, or teamwork. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

4. Be Enthusiastic and Professional

Throughout the interview, be enthusiastic about the position and the company. Show the interviewer that you are genuinely interested in the role and that you have the skills and experience to be successful. However, it is equally important to maintain a professional demeanor and to be respectful of the interviewer’s time.

5. Prepare Questions to Ask the Interviewer

At the end of the interview, the interviewer will typically ask if you have any questions. This is an opportunity for you to learn more about the company and the position, and to demonstrate your interest in the role. Prepare some thoughtful questions to ask the interviewer, such as about the company’s safety culture or the opportunities for advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lining Layer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lining Layer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.