Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lining Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

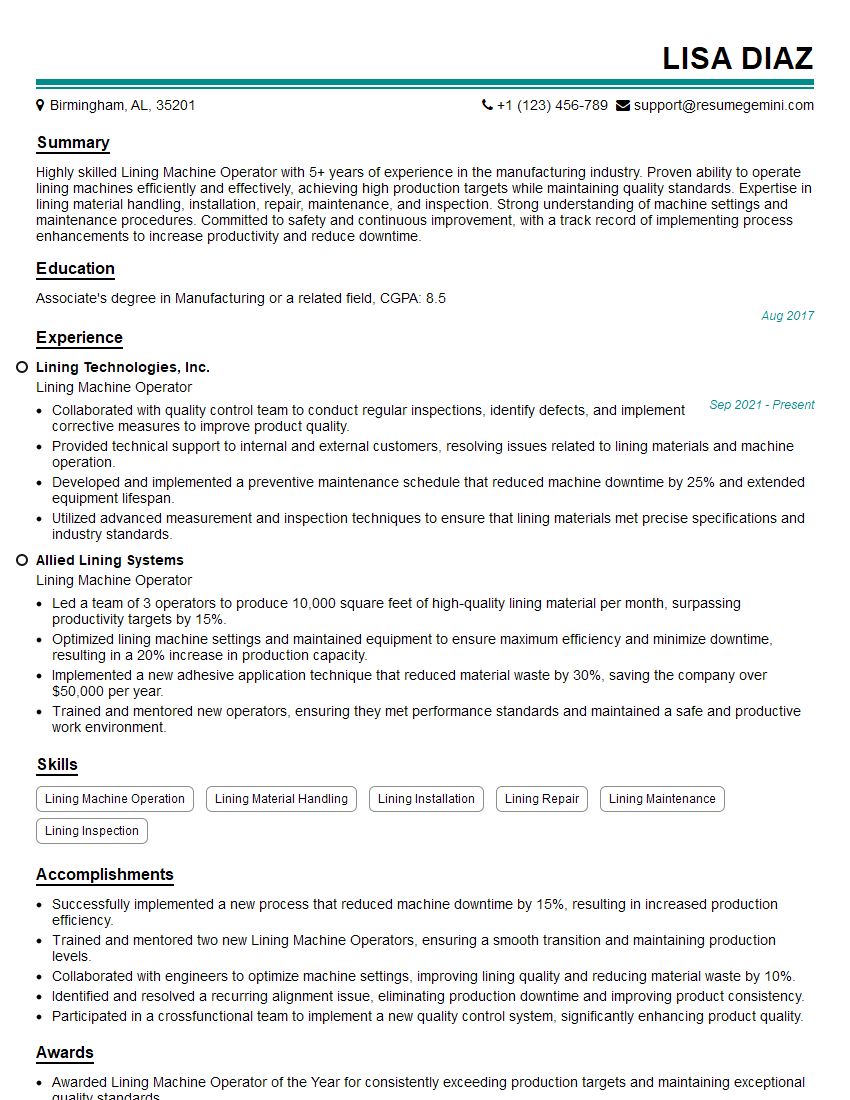

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lining Machine Operator

1. Explain the working principle of a lining machine?

The lining machine operates on the principle of extrusion to create a uniform lining inside a cylindrical object, typically a pipe or a tube. The machine comprises a rotating screw or auger that forces the lining material, such as plastic or rubber, through a heated die. As the material passes through the die, it takes the shape of the pipe or tube and adheres to its inner surface.

2. Describe the different types of lining materials used in lining machines?

Different lining materials are used in lining machines depending on the specific application and the properties required for the lining. Some common lining materials include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polyether ether ketone (PEEK)

- Ethylene chlorotrifluoroethylene (ECTFE)

3. How do you ensure the quality of the lining applied by the machine?

Ensuring the quality of the lining requires a comprehensive approach involving several key steps:

- Proper preparation of the pipe or tube surface

- Selection of the appropriate lining material

- Calibration and maintenance of the lining machine

- Monitoring of the lining process parameters

- Inspection and testing of the finished lining

4. What are the common maintenance procedures required for a lining machine?

Regular maintenance is crucial to ensure the optimal performance and longevity of the lining machine. Common maintenance procedures include:

- Cleaning the machine and its components

- Inspecting and replacing worn or damaged parts

- Lubricating moving parts

- Calibrating the machine

- Performing preventive maintenance checks

5. How do you troubleshoot common problems that may occur during lining operations?

Troubleshooting common problems during lining operations requires a systematic approach:

- Identify the problem and its symptoms

- Check the machine settings and parameters

- Inspect the condition of the lining material

- Examine the pipe or tube surface

- Refer to the machine’s user manual or consult with technical experts

6. What safety precautions should be taken while operating a lining machine?

Operating a lining machine involves potential hazards, and adhering to safety precautions is paramount:

- Wear appropriate personal protective equipment (PPE)

- Ensure proper ventilation in the work area

- Follow lockout/tagout procedures

- Be aware of moving parts and hot surfaces

- Receive proper training and authorization before operating the machine

7. Explain the role of temperature control in the lining process?

Temperature control plays a critical role in the lining process as it affects the properties and performance of the lining material:

- Excessive temperature can degrade the lining material

- Proper temperature ensures optimal adhesion to the pipe or tube

- Temperature control helps maintain the desired lining thickness and consistency

- Monitoring and adjusting temperature based on the lining material’s specifications is essential

8. Describe the different methods used to measure the thickness of the lining applied by the machine?

Measuring the thickness of the lining is crucial for quality control and ensuring the integrity of the lining. Several methods can be used:

- Ultrasonic thickness gauge

- Micrometer

- Caliper

- Cross-sectioning and microscopic examination

- Non-destructive testing (NDT) methods such as radiography or eddy current testing

9. Explain the importance of proper surface preparation before lining?

Proper surface preparation before lining is essential for ensuring a strong and durable bond between the lining material and the pipe or tube:

- Removes dirt, grease, and other contaminants

- Improves the surface roughness, enhancing adhesion

- Prevents the formation of voids or weak spots in the lining

- Standard surface preparation methods include sanding, blasting, or chemical cleaning

10. How do you ensure the lining machine is calibrated and operating at optimal efficiency?

Calibration and maintaining optimal efficiency of the lining machine are vital for consistent and high-quality lining results:

- Regularly check and adjust the machine’s settings and parameters

- Use precision measuring tools and gauges to ensure accurate calibration

- Monitor the machine’s performance and make necessary adjustments

- Follow the manufacturer’s recommended maintenance and calibration schedule

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lining Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lining Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lining Machine Operators are responsible for controlling and operating automated machinery that applies a protective lining to various types of containers and products. They work with specialized equipment to ensure that the lining process meets quality standards and production goals.

1. Machine Operation

Operate automatic lining machines to apply coatings, sealants, and other materials to containers, products, and surfaces.

- Set up and adjust machine parameters, such as material flow, coating thickness, and cure times.

- Monitor machine operation and make adjustments as needed to ensure optimal performance.

2. Material Handling

Handle and load materials, including coatings, solvents, and substrates, into the lining machine.

- Inspect materials for defects and ensure that they meet specifications.

- Maintain inventory of materials and order new supplies as needed.

3. Quality Control

Inspect lined products for defects, such as uneven coating, bubbles, or contamination.

- Perform quality control tests to ensure that products meet specifications.

- Document quality control results and report any issues to supervisors.

4. Maintenance and Troubleshooting

Perform routine maintenance and troubleshoot problems with lining machines.

- Clean and lubricate machinery according to manufacturer’s instructions.

- Identify and resolve equipment malfunctions to minimize downtime.

Interview Tips

A successful interview involves being well prepared and showing that you are genuinely interested in the opportunity. Here are some tips and tricks that you can use to ace your interview for a Lining Machine Operator position:

1. Research the Company and Industry

Before the interview, take the time to research the company, their products or services, and the industry they operate in. This knowledge will enable you to talk intelligently about the company and how your skills and experience can benefit them.

- Visit the company’s website and social media pages for information.

- Read industry news and articles to stay informed about current trends.

2. Practice Your Answers

Think about typical interview questions and how you might answer them. Prepare short, concise responses that highlight your relevant skills, experience, and qualifications.

- Consider using the STAR method to structure your answers (Situation, Task, Action, Result).

- Practice answering questions out loud in front of a mirror or with a friend or family member.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive for your interview on time. This shows the interviewer that you respect their time and that you are serious about the opportunity.

- Wear business casual attire, such as a button-down shirt, slacks, and closed-toe shoes.

- Arrive at least 10 minutes early so that you have time to relax and collect your thoughts before the interview.

4. Ask Questions

At the end of the interview, ask thoughtful questions to show that you are engaged and interested. This is an opportunity to learn more about the company, the position, and the team you would be joining.

- Ask about the company’s growth plans, their culture, and their commitment to professional development.

- Inquire about the specific responsibilities of the Lining Machine Operator role and how your skills match the requirements.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lining Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.