Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lining Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

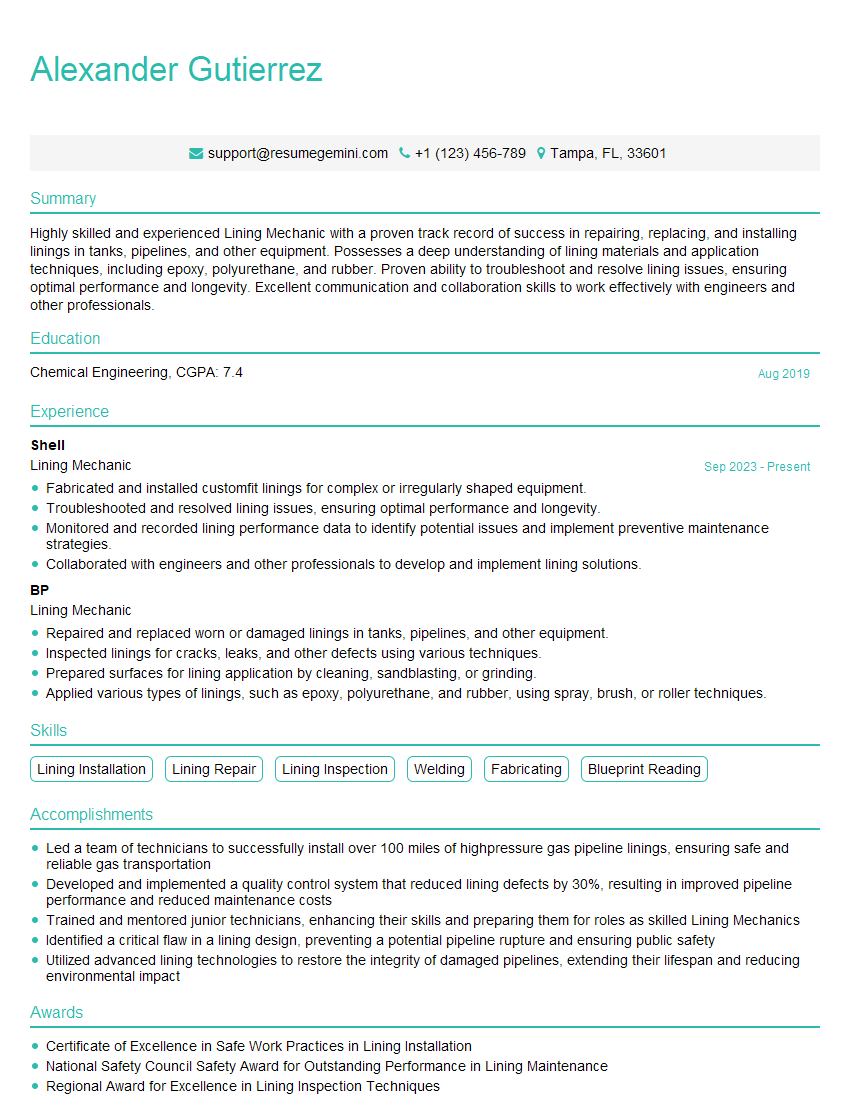

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lining Mechanic

1. What is the difference between an expansion joint and a contraction joint?

An expansion joint is designed to absorb expansion in a material, while a contraction joint is designed to absorb contraction. Expansion joints are typically made of a flexible material, such as rubber or cork, while contraction joints are typically made of a rigid material, such as concrete or metal.

2. What are the different types of lining materials used in industrial piping systems?

Metallic Linings

- Stainless steel

- Nickel-based alloys

- Titanium

Non-metallic Linings

- Polytetrafluoroethylene (PTFE)

- Polypropylene (PP)

- Ethylene propylene diene monomer (EPDM)

3. What are the advantages and disadvantages of using a flanged connection versus a welded connection for lining a pipe?

Flanged Connections

Advantages:

- Easy to assemble and disassemble

- Allow for expansion and contraction

Disadvantages:

- More expensive than welded connections

- Can leak if not properly installed

Welded Connections

Advantages:

- Less expensive than flanged connections

- Stronger and more durable

Disadvantages:

- More difficult to assemble and disassemble

- Do not allow for expansion and contraction

4. What are the different techniques used to inspect the lining of a pipe?

- Visual inspection

- Ultrasonic inspection

- Radiographic inspection

- Eddy current inspection

5. What are the most common causes of lining failure?

- Mechanical damage

- Chemical attack

- Thermal expansion and contraction

- Improper installation

6. What are the steps involved in relining a pipe?

- Remove the existing lining

- Prepare the pipe surface

- Apply the new lining

- Cure the lining

- Inspect the lining

7. What are the safety precautions that must be taken when working with lining materials?

- Wear appropriate personal protective equipment (PPE)

- Ventilate the work area

- Handle lining materials with care

- Follow the manufacturer’s instructions

8. What are the different types of equipment used to line pipes?

- Lining machines

- Sprayers

- Rollers

- Ovens

9. What is the importance of quality control in the lining process?

Quality control is important in the lining process to ensure that the lining is properly installed and will meet the desired performance requirements. Quality control measures include:

- Inspecting the lining materials

- Monitoring the lining process

- Testing the lining

- Documenting the lining process

10. What are the career advancement opportunities for a Lining Mechanic?

- Senior Lining Mechanic

- Lining Supervisor

- Lining Manager

- Quality Control Inspector

- Sales Engineer

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lining Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lining Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lining Mechanics are the masterminds behind the safety and efficiency of industrial plants and facilities. Their diverse responsibilities involve ensuring the smooth operation and integrity of various equipment and systems, ensuring compliance with safety regulations, and contributing to the overall productivity of the organization. Here are some key job responsibilities that define the role of a Lining Mechanic:

1. Equipment Installation and Maintenance

Lining Mechanics play a pivotal role in the installation, repair, and maintenance of equipment and systems found within industrial settings. This includes boilers, tanks, pumps, valves, and pipelines. They ensure that these components are installed and maintained in accordance with established standards and safety protocols, ensuring optimal performance and minimizing the risk of breakdowns.

- Install and repair linings in boilers, tanks, pumps, and other equipment.

- Maintain and repair equipment and systems to ensure optimal performance and compliance with safety regulations.

2. Material Handling and Fabrication

Working with a variety of materials is an integral part of a Lining Mechanic’s job. They handle and fabricate materials such as rubber, plastics, metals, and ceramics to create linings for equipment and systems. These linings play a crucial role in protecting equipment from corrosion, abrasion, and chemical damage, ensuring longevity and uninterrupted operation.

- Handle and fabricate materials such as rubber, plastics, metals, and ceramics.

- Create linings for equipment and systems to protect against corrosion, abrasion, and chemical damage.

3. Troubleshooting and Problem-Solving

Lining Mechanics are often called upon to troubleshoot and resolve issues related to equipment and systems. They analyze problems, identify root causes, and implement solutions to restore functionality and prevent future occurrences. Their keen observational skills and problem-solving abilities are essential to maintaining the smooth operation of industrial facilities.

- Troubleshoot and resolve issues related to equipment and systems.

- Analyze problems, identify root causes, and implement solutions.

4. Safety Compliance and Regulations

Safety is paramount in industrial settings, and Lining Mechanics play a vital role in ensuring compliance with safety regulations and protocols. They adhere to established safety standards, wear appropriate protective gear, and participate in safety training programs. Their commitment to safety helps prevent accidents and injuries, creating a safe work environment for themselves and their colleagues.

- Adhere to established safety standards and regulations.

- Wear appropriate protective gear and participate in safety training programs.

Interview Tips

Preparing for an interview for a Lining Mechanic position requires careful preparation and a clear understanding of the key responsibilities and skills required for the role. Here are some interview tips and preparation strategies to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific Lining Mechanic position you are applying for. This will give you a deep understanding of the organization’s culture, values, and the specific requirements of the role. You can visit the company’s website, read industry articles, and connect with current or former employees to gather insights.

- Visit the company’s website and read about their mission, values, and products/services.

- Read industry articles and news to stay up-to-date on the latest trends and technologies.

- Connect with current or former employees on LinkedIn to gain insights into the company culture and the role.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to showcase the skills and experience that are most relevant to the Lining Mechanic role. Quantify your accomplishments and provide specific examples of your work to demonstrate your abilities. Use keywords from the job description to ensure that your application stands out.

- Quantify your accomplishments using specific metrics and data whenever possible.

- Provide specific examples of your work that demonstrate your skills and abilities.

- Use keywords from the job description to highlight your most relevant qualifications.

3. Prepare for Common Interview Questions

Research common interview questions for Lining Mechanics and prepare thoughtful answers that showcase your expertise and enthusiasm for the role. Practice answering these questions aloud to gain confidence and fluency. Consider the following examples:

- Tell me about your experience with installing and repairing linings in boilers and tanks.

- Describe a time when you had to troubleshoot a complex issue with an industrial system.

- How do you stay up-to-date on the latest safety regulations and best practices for Lining Mechanics?

4. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions to demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more about the role and the organization. Some questions you could consider asking include:

- Can you describe the typical day-to-day responsibilities of a Lining Mechanic in this role?

- What are the opportunities for professional development and advancement within the company?

- How does the company prioritize safety and compliance in its operations?

5. Follow Up Professionally

After the interview, send a thank-you note to the hiring manager or recruiter within 24 hours. Express your appreciation for the opportunity to interview and reiterate your interest in the position. You can also use this opportunity to highlight any additional qualifications or experiences that you may have forgotten to mention during the interview.

- Send a thank-you note within 24 hours of the interview.

- Express your appreciation for the opportunity to interview and reiterate your interest in the position.

- Highlight any additional qualifications or experiences that you may have forgotten to mention during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lining Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.