Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Link Knitting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

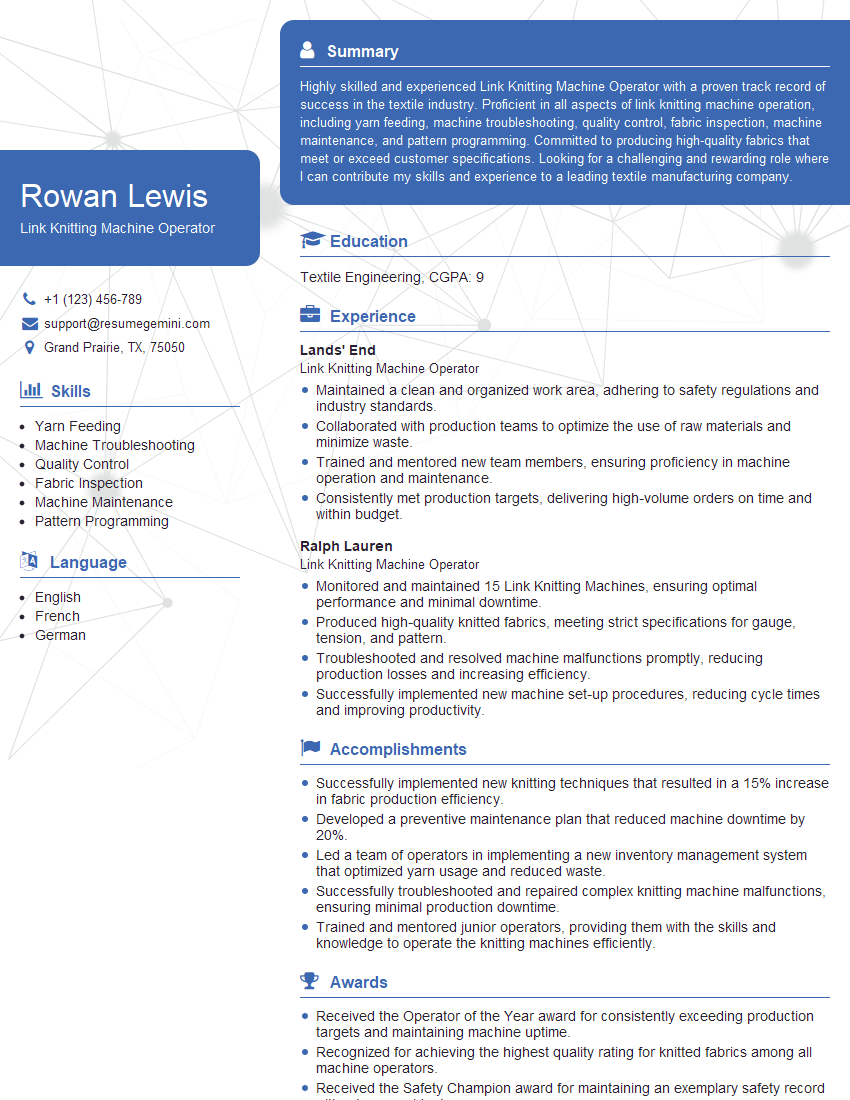

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Link Knitting Machine Operator

1. Describe the different types of Link Knitting Machines and their functions?

There are two main types of Link Knitting Machines: single-jersey and double-jersey

- Single-jersey machines produce a single layer of fabric, which is often used for T-shirts, underwear, and sportswear.

- Double-jersey machines produce a two-layer fabric, which is often used for sweaters, blankets, and outerwear.

2. Explain the process of setting up and operating a Link Knitting Machine?

Setting Up

- Mount the machine on a stable surface.

- Install the yarn cones on the yarn creels.

- Thread the yarn through the tensioners and guides.

- Set the stitch and pattern parameters on the machine’s control panel.

Operating

- Start the machine and monitor the knitting process.

- Adjust the tension and speed of the machine as needed.

- Stop the machine when the desired length of fabric has been produced.

3. What are the common problems that can occur when operating a Link Knitting Machine?

Some common problems include:

- Yarn breakage – This can be caused by incorrect tension settings, worn needles, or damaged yarn.

- Dropped stitches – This can be caused by loose tension, incorrect needle timing, or damaged needles.

- Needle breakage – This can be caused by excessive tension, improper handling, or worn needles.

- Fabric defects – These can be caused by incorrect stitch settings, improper tension, or damaged needles.

4. What are the safety precautions that must be followed when operating a Link Knitting Machine?

- Keep hands away from moving parts.

- Wear appropriate safety gear, such as safety glasses and gloves.

- Never operate the machine when it is unattended.

- Unplug the machine before performing any maintenance or repairs.

5. What is the difference between a tuck stitch and a float stitch?

- Tuck stitch – A tuck stitch is a stitch in which the yarn is held behind the needle instead of being knitted. This creates a decorative effect.

- Float stitch – A float stitch is a stitch in which the yarn is carried across multiple needles without being knitted. This creates a pattern or design.

6. How do you troubleshoot a Link Knitting Machine that is not producing fabric correctly?

- Check the yarn tension.

- Check the needle timing.

- Check for damaged needles.

- Check the stitch settings.

- Check the fabric defect.

7. What are the different needle gauges used in Link Knitting Machines?

Common needle gauges used in Link Knitting Machines include:

- 3.5 needles per inch (needles per 2.5 cm)

- 5 needles per inch (needles per 2 cm)

- 7 needles per inch (needles per 1.4 cm)

- 9 needles per inch (needles per 1.1 cm)

- 12 needles per inch (needles per 0.8 cm)

8. What are the factors that affect the quality of fabric produced by a Link Knitting Machine?

- Yarn quality

- Machine tension

- Needle condition

- Stitch settings

- Operator skill

9. What is the difference between a rib stitch and a plain stitch?

- Rib stitch – A rib stitch is a stitch in which alternating needles are knit and purled. This creates a ribbed effect.

- Plain stitch – A plain stitch is a stitch in which all needles are knit. This creates a smooth, flat fabric.

10. How do you calculate the amount of yarn needed to produce a specific length of fabric?

To calculate the amount of yarn needed, you need to know the following:

- The length of fabric you want to produce.

- The stitch density of the fabric.

- The yarn count.

Once you have this information, you can use the following formula:

Yarn length = Fabric length x Stitch density x Yarn countInterviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Link Knitting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Link Knitting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Link Knitting Machine Operator is responsible for operating and maintaining link knitting machines, ensuring the production of high-quality knitted fabrics.

1. Machine Operation and Maintenance

Operate link knitting machines to produce various types of knitted fabrics, such as lace, mesh, and other specialty fabrics.

- Set up and adjust machines according to production requirements.

- Monitor machine operations and make necessary adjustments to ensure smooth operation.

2. Quality Control

Inspect knitted fabrics for defects, such as yarn breaks, dropped stitches, and incorrect patterns.

- Identify and correct defects promptly to maintain fabric quality.

- Collaborate with quality control team to ensure adherence to production standards.

3. Yarn Management

Manage yarn inventory, monitor yarn tension, and replenish yarn as needed.

- Inspect yarn quality to ensure it meets production specifications.

- Maintain proper yarn tension to prevent fabric defects.

4. Troubleshooting and Repairs

Troubleshoot and resolve machine malfunctions and fabric defects.

- Identify the cause of problems and implement solutions to minimize downtime.

- Perform basic repairs and maintenance tasks to keep machines operational.

Interview Tips

Preparing thoroughly for a Link Knitting Machine Operator interview can significantly enhance your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Industry

Take the time to research the company’s website, social media pages, and industry news to gain insights into their business, culture, and recent developments.

- This knowledge will demonstrate your interest and enthusiasm for the position.

- It will also help you align your answers with the company’s goals and aspirations.

2. Practice Your Technical Skills

As a Link Knitting Machine Operator, you will be expected to possess strong technical skills. Practice operating and troubleshooting knitting machines to demonstrate your proficiency.

- You can use online simulators or reach out to industry contacts to gain hands-on experience.

- Emphasizing your technical abilities will set you apart from other candidates.

3. Highlight Your Quality Control Experience

Quality control is crucial in this role. Highlight your experience in identifying and correcting fabric defects, as well as your understanding of industry quality standards.

- Provide specific examples of how you have implemented quality control measures.

- Quantifying your results, such as reducing defect rates, will further strengthen your candidacy.

4. Showcase Your Problem-Solving Abilities

Link Knitting Machine Operators often encounter machine malfunctions and fabric defects. Demonstrate your problem-solving skills by describing how you have successfully diagnosed and resolved issues.

- Use the STAR method to provide structured answers: Situation, Task, Action, Result.

- Focus on the steps you took to analyze the problem, identify the root cause, and implement effective solutions.

5. Emphasize Teamwork and Communication

Link Knitting Machine Operators often work as part of a team and interact with other departments. Highlight your teamwork and communication skills.

- Describe how you have collaborated with colleagues to achieve production goals.

- Provide examples of how you have effectively communicated with supervisors, quality control personnel, and maintenance technicians.

Next Step:

Now that you’re armed with the knowledge of Link Knitting Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Link Knitting Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini