Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Linotype Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

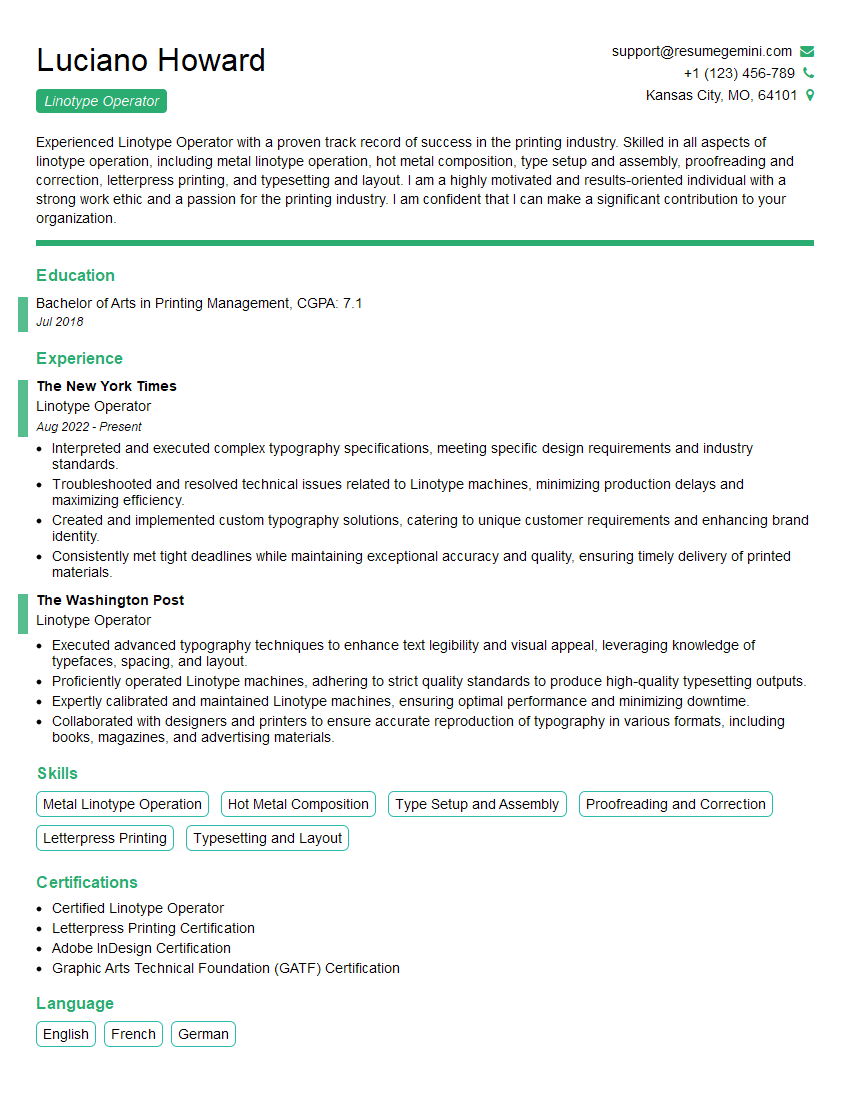

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Linotype Operator

1. What is the process of linotype?

Linotype is a process of typesetting text using a machine that casts individual lines of type from molten metal. Here’s an overview of the process:

- Keyboarding: The operator uses a special keyboard to input the text to be set.

- Matrix Assembly: The machine selects matrices (metal molds) corresponding to each character from a magazine.

- Mold Formation: The matrices are assembled into a line-casting mold.

- Metal Casting: Molten metal (usually lead) is pumped into the mold, filling the character cavities.

- Line Formation: The cooled metal solidifies to form a solid line of type.

- Line Ejection: The line of type is ejected from the mold and is ready for use in typesetting.

2. What are the different types of linotype machines?

There are several types of linotype machines, each with its own features and capabilities. Some common types include:

- Hot Metal Linotype: The traditional linotype machine, it uses molten metal to cast type.

- Cold Metal Linotype: A variation that uses a cold metal composition to cast type.

- Digital Linotype: Modern linotype machines that use digital technology to create and output type.

- Intertype: A competing typesetting system that was similar to linotype but had some unique features.

3. What are the advantages of using a linotype machine?

Linotype machines offer several advantages, including:

- High-Quality Output: Linotype machines produce high-quality, sharp, and legible type.

- Speed and Efficiency: They can set type quickly and efficiently, especially for large volumes of text.

- Versatility: Linotype machines can produce type in a wide range of fonts, sizes, and styles.

- Durability: Metal type produced by linotype machines is durable and long-lasting.

4. What are the disadvantages of using a linotype machine?

Along with advantages, linotype machines also have some disadvantages, such as:

- Complexity and Maintenance: Linotype machines are complex and require skilled operators and regular maintenance.

- Environmental Concerns: Hot metal linotype machines release lead fumes, which can pose health risks.

- Limited Availability: With the advent of digital typesetting, linotype machines have become less common and may be difficult to find.

- Cost: Linotype machines and their operation can be expensive.

5. How can you ensure the accuracy and quality of the output from a linotype machine?

To ensure accuracy and quality, I follow several best practices:

- Careful Proofreading: I thoroughly proofread the input text before typesetting to identify and correct any errors.

- Proper Machine Maintenance: I perform regular maintenance on the linotype machine to ensure it’s operating correctly.

- Matrix Inspection: I inspect the matrices regularly to ensure they are in good condition and produce sharp characters.

- Control over Casting Temperature: I carefully control the temperature of the molten metal during casting to minimize defects.

- Quality Check: After casting, I inspect each line of type to ensure it meets the required standards for quality.

6. What safety precautions are important when operating a linotype machine?

Safety is paramount when operating a linotype machine. I prioritize these precautions:

- Protective Gear: I always wear appropriate protective gear, including gloves, safety glasses, and a dust mask.

- Proper Ventilation: I ensure the work area is well-ventilated to minimize exposure to lead fumes.

- Careful Handling of Molten Metal: I handle molten metal with great care to prevent burns or accidents.

- Electrical Safety: I follow electrical safety protocols to avoid electrical shocks.

- Machine Maintenance: I regularly inspect and maintain the machine to prevent malfunctions and accidents.

7. How do you handle troubleshooting common issues with a linotype machine?

Troubleshooting linotype machines requires a combination of technical skills and experience. Here’s my approach:

- Identify the Issue: I start by carefully observing the machine and identifying the specific issue.

- Consult Manuals and Resources: I refer to technical manuals and other resources to find potential solutions.

- Check Mechanical Components: I inspect mechanical components such as gears, matrices, and molds for any damage or misalignment.

- Test and Adjust: I conduct tests and make necessary adjustments to resolve the issue.

- Seek Expert Help: If the issue persists or is complex, I consult with experienced technicians or manufacturers for assistance.

8. What are your knowledge and experience with different typesetting systems?

In addition to linotype, I have knowledge and experience with other typesetting systems, including:

- Digital Typesetting: I am proficient in using digital typesetting software and technologies.

- Cold Type Composition: I have experience with cold type composition techniques, such as phototypesetting and filmsetting.

- Letterpress Printing: I am familiar with letterpress printing techniques and can integrate linotype output into letterpress workflows.

9. How do you stay up-to-date with the latest developments in typesetting technology?

To stay current with the latest developments in typesetting technology, I actively engage in the following practices:

- Industry Events and Conferences: I attend industry events and conferences to learn about new technologies and trends.

- Technical Publications and Articles: I read technical publications and articles to stay informed about advancements in the field.

- Online Resources and Forums: I participate in online resources and forums to connect with other professionals and exchange knowledge.

- Training and Workshops: I seek opportunities for training and workshops to enhance my skills and learn about new technologies.

10. What are your career goals and aspirations as a Linotype Operator?

As a Linotype Operator, my career goals and aspirations include:

- Preserving Historical Techniques: I am passionate about preserving the art of linotype typesetting and using my skills to contribute to historical printing projects.

- Exploring Creative Applications: I am eager to explore creative applications of linotype, such as in fine art, design, and experimental typography.

- Mentoring and Training: I am committed to sharing my knowledge and skills by mentoring and training aspiring linotype operators.

- Promoting the Craft: I am an advocate for the linotype craft and actively promote its importance and value in the printing industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Linotype Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Linotype Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Linotype Operator is responsible for operating and maintaining linotype machines to produce metal or plastic type for use in printing processes.

1. Prepare the Machine

Setting up and aligning the Linotype machine, ensuring that all components are functioning correctly.

2. Typesetting

- Operating the keyboard to input text, selecting appropriate fonts and sizes.

- Casting metal or plastic lines of type, known as “slugs.”

- Assembling slugs into galleys or forms, ready for printing.

3. Proofreading

- Checking typeset material for errors in spelling, grammar, and formatting.

- Making necessary corrections and adjustments.

4. Machine Maintenance

- Performing routine maintenance and cleaning of the Linotype machine.

- Troubleshooting and repairing minor issues.

- Coordinating major repairs with maintenance personnel.

5. Collaboration

- Working closely with editors, proofreaders, and other printing professionals.

- Adhering to established printing standards and specifications.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some key tips to help you ace the interview for a Linotype Operator position:

1. Research the Company and Position

- Visit the company’s website to learn about their history, mission, and products or services.

- Read industry publications and trade magazines to stay up-to-date on advancements in printing technology.

2. Practice Your Skills

- If possible, practice using a Linotype machine or similar equipment before the interview.

- Demonstrating your proficiency in typesetting, proofreading, and machine operation can greatly impress the interviewer.

3. Emphasize Your Experience

- Highlight your relevant experience in typesetting, printing, or machine operation.

- Quantify your accomplishments and provide specific examples of your contributions.

4. Be Enthusiastic and Professional

- Show genuine interest in the position and the company.

- Maintain a positive and confident demeanor throughout the interview.

5. Prepare Questions for the Interviewer

- Asking thoughtful questions at the end of the interview demonstrates your engagement and interest.

- Prepare questions that focus on the company’s printing processes, technology, and future goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Linotype Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.