Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Linter Drier Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

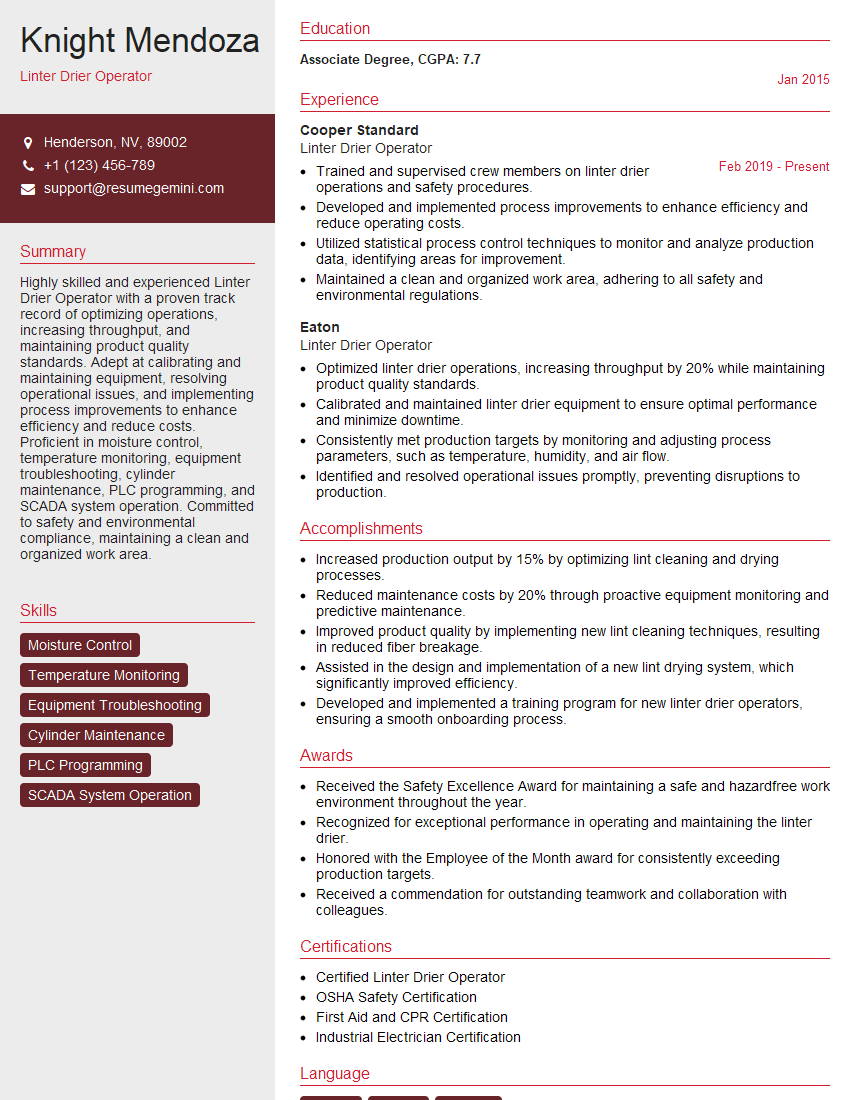

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Linter Drier Operator

1. What are your responsibilities as a Linter Drier Operator?

As a Linter Drier Operator, my primary responsibilities include:

- Operating and maintaining linters and driers used in the textile industry

- Ensuring optimal machine performance to achieve desired lint quality and production efficiency

- Monitoring and adjusting process parameters such as temperature, moisture content, and airflow

- Performing regular maintenance and troubleshooting of equipment to prevent breakdowns

- Collaborating with other team members to ensure seamless production operations

2. How do you ensure the quality of the lint produced?

Quality Control Measures

- Regularly monitoring lint moisture content to meet specifications

- Adjusting linter settings to optimize fiber separation and minimize impurities

- Conducting visual inspections and laboratory tests to assess lint quality

Preventive Maintenance

- Performing scheduled inspections and maintenance to prevent equipment malfunctions

- Ensuring proper lubrication and cleaning of all components

- Replacing worn or damaged parts promptly to maintain machine efficiency

3. What troubleshooting techniques do you use when there is a problem with the linter or drier?

When troubleshooting issues with the linter or drier, I follow a systematic approach:

- Identify the symptoms of the problem and gather relevant data

- Consult maintenance manuals and technical documentation for guidance

- Perform visual inspections and check for any obvious faults

- Use diagnostic tools and meters to identify potential electrical or mechanical issues

- Isolate the problem by systematically testing different components

- Replace or repair faulty components as necessary

- Test the machine after repairs to ensure proper functioning

4. How do you handle emergency situations, such as a fire or equipment failure?

In an emergency situation, I prioritize the safety of myself and others:

- Evacuate the area immediately and alert appropriate personnel

- Use fire extinguishers or other safety equipment to contain the situation

- Report the incident to the supervisor and follow established emergency protocols

- Assist in isolating the source of the problem and prevent further damage

- Cooperate with emergency responders and provide necessary information

5. How do you stay up-to-date with advancements in linter and drier technology?

To stay current with industry developments, I engage in the following activities:

- Attend industry conferences and exhibitions to learn about new technologies

- Read trade publications and technical journals to stay informed about best practices

- Participate in online forums and discussion groups to connect with other professionals

- Receive training from equipment manufacturers and suppliers

- Experiment with different settings and configurations to optimize machine performance

6. How do you work as part of a team?

I believe effective teamwork is crucial in a production environment:

- Communicate clearly and regularly with colleagues to ensure coordination

- Share knowledge and expertise to support the team’s goals

- Assist other team members with tasks and responsibilities

- Provide constructive feedback and support to improve team performance

- Maintain a positive and collaborative work environment

7. What are the key performance indicators (KPIs) used to evaluate your performance?

My performance is typically measured against the following KPIs:

- Lint quality and consistency

- Production efficiency and output

- Equipment uptime and reliability

- Maintenance costs and downtime

- Customer satisfaction and feedback

8. How do you handle working in a fast-paced and demanding environment?

I thrive in fast-paced environments and maintain my composure under pressure:

- Prioritize tasks and manage my time effectively

- Stay focused and avoid distractions to maintain productivity

- Delegate responsibilities and seek support when necessary

- Maintain a positive attitude and remain adaptable to changing circumstances

- Take regular breaks to prevent burnout and maintain mental clarity

9. What motivates you to succeed in this role?

I am motivated by the following factors:

- Contributing to the production of high-quality textiles

- Solving technical challenges and improving machine performance

- Working as part of a team to achieve common goals

- Continuous learning and professional development

- Making a positive impact on the industry and environment

10. Describe a time when you successfully implemented a process improvement in your previous role.

In my previous role, I identified an opportunity to improve the efficiency of the linter drying process:

- Analyzed the existing process and identified bottlenecks

- Researched and evaluated new drying technologies

- Proposed a solution that involved upgrading the drying equipment

- Collaborated with engineers and technicians to implement the upgrade

- The new system significantly reduced drying time, increased production output, and improved lint quality

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Linter Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Linter Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Linter Drier Operator plays a crucial role in the cotton processing industry, ensuring the correct drying and purification of cotton lint. Their primary responsibilities include:

1. Machine Operation

Operate and maintain linter drier machines, monitoring temperatures, feed rates, and overall machine performance.

- Adjust settings to optimize drying efficiency and minimize lint damage.

- Troubleshoot and resolve machine malfunctions, ensuring smooth operation.

2. Quality Control

Monitor and ensure the quality of the dried lint, meeting established standards.

- Conduct visual inspections of lint for dryness, color, and cleanliness.

- Collect samples for laboratory testing to verify moisture content and other quality parameters.

3. Production Management

Maintain production schedules, ensuring timely delivery of dried lint to downstream processes.

- Coordinate with other departments to schedule maintenance and equipment repairs.

- Monitor inventory levels and communicate any potential shortages or surpluses.

4. Safety and Maintenance

Adhere to all safety regulations and practices, ensuring a safe work environment.

- Perform regular maintenance tasks on linter drier machines, including cleaning, lubrication, and filter replacement.

- Report any potential hazards or safety concerns to supervisors.

Interview Tips

Preparing for an interview as a Linter Drier Operator requires careful planning and research. Here are some helpful tips to help you ace your interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and reputation in the industry. Understand the role of linter drying in the cotton processing value chain.

- Visit the company website, read industry publications, and attend industry events.

- Network with professionals in the field and seek insights into the company’s culture and operations.

2. Highlight Your Skills and Experience

Emphasize your technical skills in operating and maintaining linter drier machines, as well as your experience in quality control and production management.

- Quantify your accomplishments whenever possible, using specific metrics and examples.

- Demonstrate your ability to troubleshoot and resolve machine issues independently.

3. Prepare for Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivations. Consider the following:

- “Describe your experience in operating and maintaining linter drier machines.”

- “How do you ensure the quality of dried lint meets established standards?”

- “Tell me about a time you successfully resolved a major machine malfunction.”

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview shows your interest in the company and the position. Prepare questions that demonstrate your knowledge of the industry and your enthusiasm for the role.

- “What are the company’s goals for improving the efficiency of its linter drying process?”

- “Are there any opportunities for professional development and advancement within the organization?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Linter Drier Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!