Are you gearing up for an interview for a Linter Saw Sharpener position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Linter Saw Sharpener and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

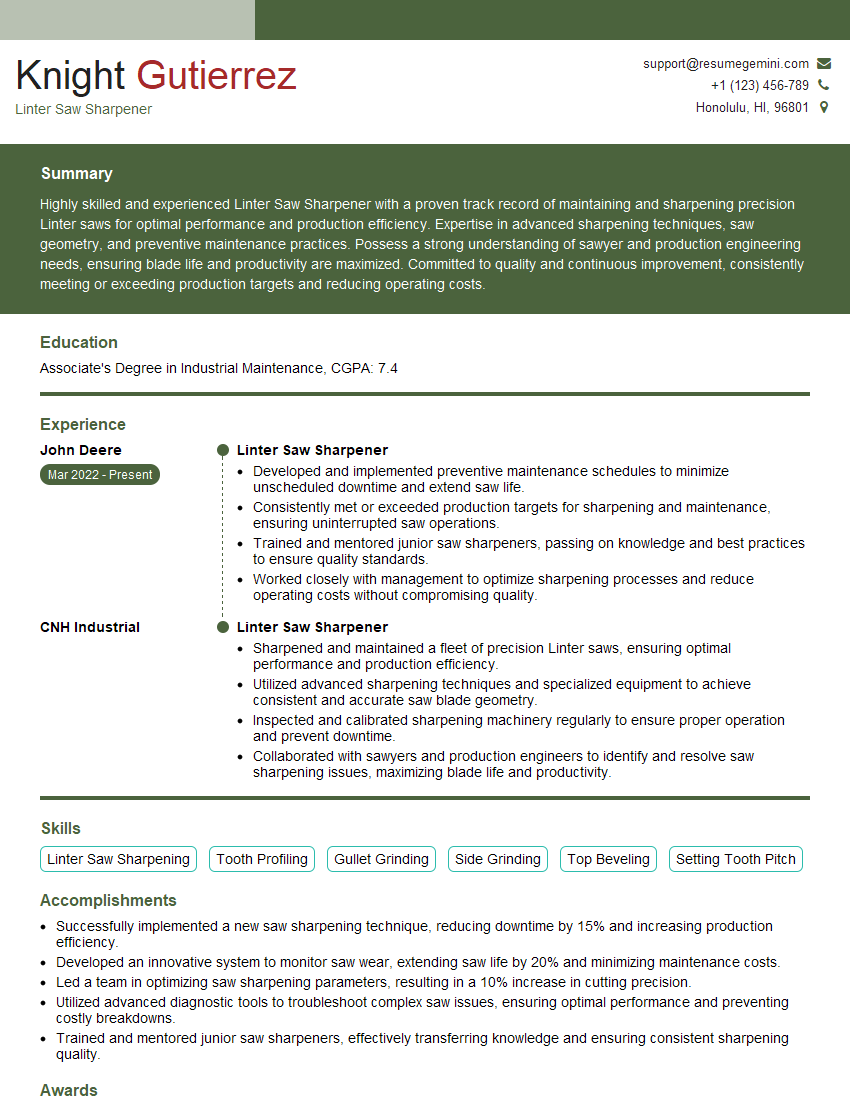

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Linter Saw Sharpener

1. What are the different types of linter saw blades and their applications?

- Circular saw blades: Used for cutting curves, ripping, and crosscutting.

- Band saw blades: Used for cutting curves, resawing, and cutting veneers.

- Jigsaw blades: Used for cutting intricate shapes and curves in thin materials.

- Reciprocating saw blades: Used for cutting straight lines, demolition work, and pruning.

2. Describe the process of sharpening a linter saw blade.

Surface grinding

- Mount the blade on a grinding machine and adjust the grinding wheel to the correct angle.

- Grind the blade surface to remove any nicks, burrs, or other imperfections.

Tooth sharpening

- Set the grinding wheel to the correct angle for the tooth profile.

- Grind each tooth individually, following the original tooth shape.

Setting teeth

- Use a setting tool to bend the teeth alternately to the left and right to create clearance.

3. What are the common problems encountered when sharpening linter saw blades?

- Overheating: Can lead to blade damage and reduced blade life.

- Inconsistent grinding: Can result in uneven tooth profiles and reduced cutting efficiency.

- Incorrect tooth angle: Can affect the blade’s cutting performance and durability.

- Inadequate clearance: Can cause binding and premature blade wear.

4. How do you ensure the quality of sharpened linter saw blades?

- Inspect blades visually for any defects or imperfections.

- Use measuring tools to verify tooth angles, tooth profiles, and clearance.

- Test blades on a saw to ensure proper cutting performance.

5. What is the importance of proper saw blade maintenance?

- Extends blade life and reduces the need for frequent sharpening.

- Improves cutting efficiency and accuracy.

- Prevents accidents and injuries.

6. Describe the different types of sharpening equipment used for linter saw blades.

Manual sharpeners

- Hand-held tools used for light sharpening and touch-ups.

Semi-automatic sharpeners

- Electrically powered machines that require manual feeding of the blade.

Fully automatic sharpeners

- Computerized machines that automate the entire sharpening process.

7. What are the safety precautions when sharpening linter saw blades?

- Wear appropriate safety gear, including eye protection, gloves, and hearing protection.

- Ensure the sharpening equipment is in good working condition.

- Follow the manufacturer’s instructions for safe operation.

- Never attempt to sharpen a saw blade that is damaged or has missing teeth.

8. How do you determine when a linter saw blade needs to be sharpened?

- Reduced cutting performance

- Uneven or rough cuts

- Excessive vibration or noise

- Visual inspection of dull or damaged teeth

9. What are the common causes of saw blade damage?

- Improper sharpening techniques

- Cutting hard or abrasive materials

- Excessive wear and tear

- Lack of maintenance

10. How do you troubleshoot a saw blade that is not cutting properly?

- Inspect the blade for any damage or defects.

- Check the tooth angles and clearance.

- Test the blade on a saw to identify the issue.

- Adjust the sharpening equipment or blade settings as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Linter Saw Sharpener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Linter Saw Sharpener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Linter Saw Sharpener is responsible for maintaining the sharpness of saws used in the linter room, where cotton fibers are separated from seeds. Key responsibilities include:

1. Sharpening Saws

Inspect and sharpen saws to ensure they meet the required sharpness standards. Use specialized equipment such as grinders, honing stones, and calipers to sharpen and adjust saw teeth.

2. Equipment Maintenance

Maintain and repair sharpening equipment, including grinders, honing stones, and calipers, to ensure proper functioning.

3. Saw Cleaning

Clean saws thoroughly to remove debris and ensure optimal performance.

4. Quality Control

Inspect sharpened saws to ensure they meet quality standards and specifications. Test saws on cutting materials to verify sharpness.

5. Inventory Management

Maintain an inventory of saw sharpening supplies and ensure timely replenishment.

Interview Tips

To ace the interview for a Linter Saw Sharpener position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and services. Understand the cotton processing industry and the role of a Linter Saw Sharpener within it.

2. Highlight Relevant Skills

Emphasize your experience and skills in saw sharpening, equipment maintenance, and quality control. Provide specific examples of how you have contributed to the efficient operation of a linter room.

3. Show Eagerness to Learn

Express your willingness to learn new techniques and technologies related to saw sharpening. Demonstrate your commitment to continuous improvement and professional development.

4. Prepare for Technical Questions

Study basic saw sharpening principles, such as tooth geometry, rake angle, and clearance. Be prepared to answer questions about sharpening equipment, saw maintenance, and quality control.

5. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?”

6. Ask Insightful Questions

During the interview, ask questions that show your interest in the role and the company. This demonstrates your engagement and enthusiasm for the position.

7. Dress Professionally

Make a good impression by dressing appropriately for the interview. Opt for business casual attire or a suit.

8. Be Punctual and Courteous

Arrive on time for your interview and be polite and respectful to the interviewers. This shows that you value their time and professionalism.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Linter Saw Sharpener interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!