Feeling lost in a sea of interview questions? Landed that dream interview for Liquefaction and Regasification Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Liquefaction and Regasification Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

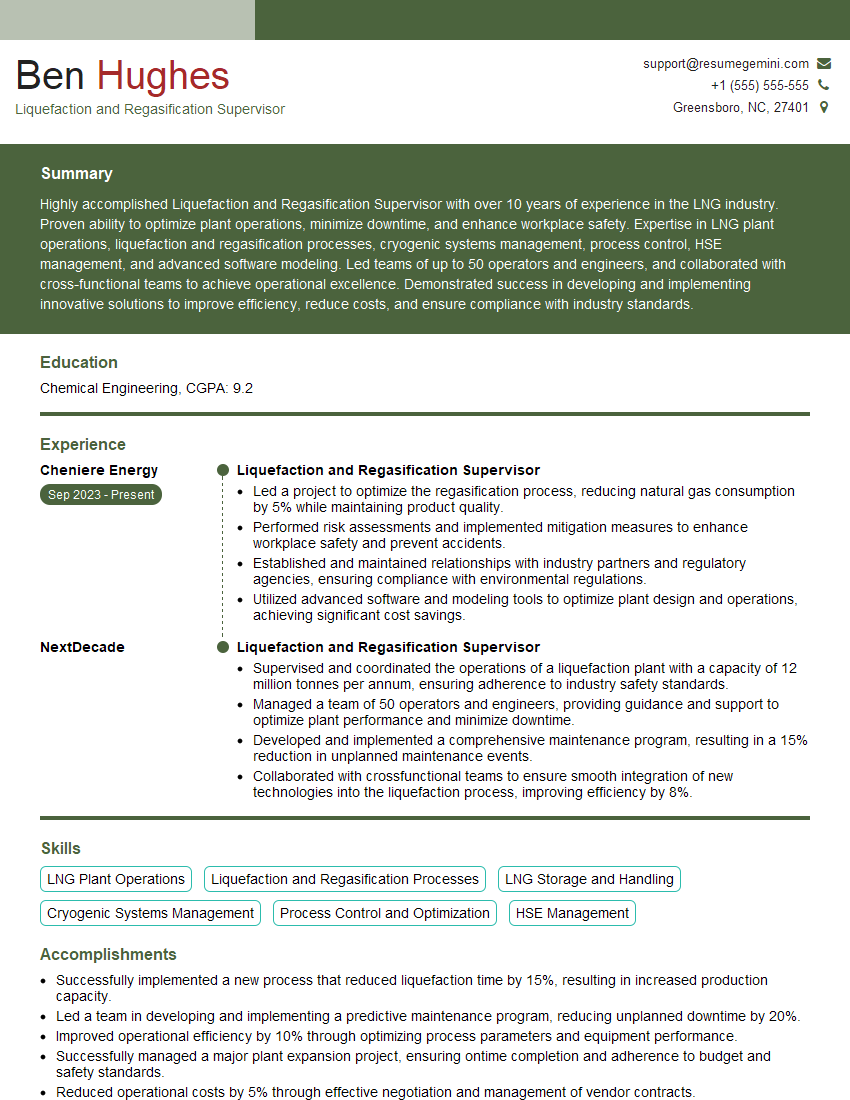

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liquefaction and Regasification Supervisor

1. Explain the key responsibilities of a Liquefaction and Regasification Supervisor?

- Supervising liquefaction and regasification operations to ensure compliance with safety, environmental, and quality standards

- Monitoring and controlling process parameters to optimize plant efficiency and product quality

- Troubleshooting and resolving operational issues, implementing corrective actions to minimize downtime

- Leading shift personnel, providing training and ensuring adherence to procedures and protocols

- Collaborating with cross-functional teams to improve plant performance and meet production targets

2. Describe the liquefaction process, including the key equipment involved?

Liquefaction Process

- Pretreatment of natural gas to remove impurities

- Cooling the gas to cryogenic temperatures (-162°C) through a series of heat exchangers

- Condensation and separation of hydrocarbons into liquid and gas phases

- Storage of liquefied natural gas (LNG) in cryogenic tanks

Key Equipment

- Cooling coils and heat exchangers

- Compressors and pumps

- LNG storage tanks

- Safety systems and instrumentation

3. How do you ensure the safe operation of a regasification facility?

- Adhering to strict safety protocols and procedures

- Regularly inspecting and maintaining equipment

- Implementing emergency response plans and training personnel

- Monitoring and controlling process variables to prevent hazards

- Collaborating with safety professionals to identify and mitigate risks

4. Discuss the environmental impact of liquefaction and regasification processes?

- Greenhouse gas emissions during the cooling and compression stages

- Potential for leaks and fugitive emissions

- Noise and visual impact of facilities

- Water usage and wastewater treatment

- Mitigation strategies include emissions monitoring, leak detection systems, and environmental management plans

5. Describe the maintenance procedures for cryogenic equipment used in liquefaction and regasification?

- Regular inspections and preventive maintenance

- Calibration of temperature sensors and pressure gauges

- Leak testing and valve maintenance

- Scheduled overhauls and component replacements

- Adherence to vendor-recommended maintenance guidelines

6. Explain the role of automation and control systems in liquefaction and regasification?

- Monitoring and controlling process parameters in real-time

- Optimizing plant efficiency and product quality

- Detecting and responding to abnormal conditions

- Providing data for performance analysis and reporting

- Improving safety by reducing human error

7. How do you handle emergencies and unplanned outages in liquefaction and regasification operations?

- Following established emergency response protocols

- Communicating clearly and coordinating with relevant personnel

- Identifying the root cause of the incident and implementing corrective actions

- Prioritizing safety and minimizing the impact on production

- Conducting post-incident reviews and sharing lessons learned

8. Discuss the regulatory requirements and industry standards applicable to liquefaction and regasification operations?

- Safety regulations (e.g., OSHA, EPA)

- Environmental regulations (e.g., Clean Air Act)

- Industry codes and standards (e.g., ASME, API)

- Facility-specific operating permits

- Compliance with regulations and standards is essential for safety, reliability, and environmental protection

9. How do you stay up-to-date with advancements in liquefaction and regasification technology?

- Attending industry conferences and workshops

- Reading technical publications and research papers

- Networking with peers and experts in the field

- Participating in professional development programs

- Continuous learning is essential to stay abreast of industry trends and improve expertise

10. Describe your experience in managing large-scale liquefaction and regasification facilities?

- Supervising a team of engineers and operators

- Ensuring smooth and efficient plant operations

- Implementing performance improvement initiatives

- Collaborating with cross-functional teams to optimize plant performance and meet production targets

- Successfully managing large-scale liquefaction and regasification facilities is a testament to leadership skills and technical expertise

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liquefaction and Regasification Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liquefaction and Regasification Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Oversee Liquefaction and Regasification Operations

Responsbile for all aspects of liquifaction and regasification operations, including plant operations, maintenance and safety.

- Manage liquefaction and regasification process, ensuring adherence to established procedures and industry standards.

- Maintain safe and efficient operations by monitoring key process parameters, identifying potential hazards, and implementing corrective actions.

2. Supervise and Train Plant Personnel

Direct and oversee a team of plant personnel, providing guidance, training, and support.

- Conduct regular training sessions to ensure staff are up to date on best practices and safety protocols.

- Evaluate and provide feedback on employee performance, fostering professional development and growth.

3. Collaborate with Cross-Functional Teams

Work closely with engineering, maintenance, and other departments to ensure smooth operation and continuous improvement.

- Participate in problem-solving sessions, providing expertise on liquefaction and regasification processes.

- Contribute to the development and implementation of new technologies and innovations.

4. Maintain Compliance with Regulations and Standards

Ensure compliance with all applicable environmental, health, and safety regulations and industry standards.

- Monitor and control emissions, adhering to environmental regulations and minimizing environmental impact.

- Conduct regular audits to ensure compliance and identify areas for improvement.

Interview Tips

Preparing for an interview for a Liquefaction and Regasification Supervisor position requires thorough knowledge of the role, the industry, and your own skills and experience. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Industry

Take the time to learn about the company’s history, operations, and the specific role you are applying for. Research the liquefaction and regasification industry to understand its key players, trends, and challenges.

2. Highlight Your Experience and Skills

Emphasize your relevant experience and skills in liquefaction and regasification operations. Quantify your accomplishments using specific metrics whenever possible.

3. Prepare for Technical Questions

Expect technical questions related to liquefaction and regasification processes, process control, and safety protocols. Review basic principles and be prepared to discuss your understanding of the industry.

4. Demonstrate Leadership and Team Skills

Supervisory roles require strong leadership and team management skills. Provide examples of how you have motivated, developed, and collaborated with teams to achieve results.

5. Practice Your Answers

Practice answering interview questions in front of a mirror or with a friend. This will help you feel more confident and articulate your answers more effectively.

6. Ask Questions

Asking thoughtful questions at the end of the interview shows your interest in the role and the company. Prepare questions related to the company’s growth strategy, sustainability initiatives, or any other areas you find interesting.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Liquefaction and Regasification Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.