Feeling lost in a sea of interview questions? Landed that dream interview for Liquefied Natural Gas Plant Operator (LNG Plant Operator) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Liquefied Natural Gas Plant Operator (LNG Plant Operator) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

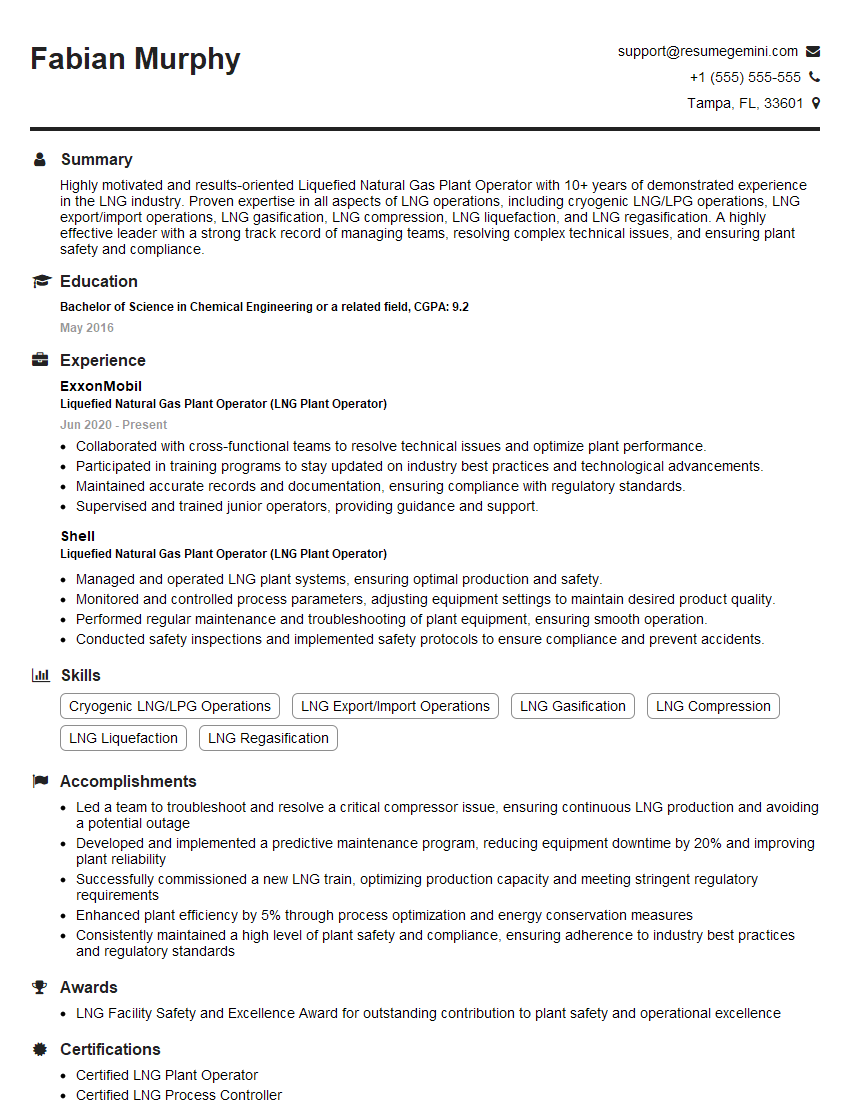

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liquefied Natural Gas Plant Operator (LNG Plant Operator)

1. Describe the overall process of liquefying natural gas (LNG) at an LNG plant.

The overall process of liquefying natural gas (LNG) at an LNG plant involves several key steps:

- Gas treatment: The incoming natural gas is first treated to remove impurities such as water, sulfur, and carbon dioxide.

- Pre-cooling: The treated gas is then pre-cooled using a series of heat exchangers to reduce its temperature.

- Liquefaction: The pre-cooled gas is further cooled and liquefied in a liquefaction unit. This involves using a refrigerant or mixed refrigerant to extract heat from the gas, causing it to condense into a liquid.

- Storage and loading: The liquefied LNG is stored in specially designed storage tanks. When ready for shipment, the LNG is transferred to LNG tankers for transportation to receiving terminals.

2. Explain the role of cryogenic heat exchangers in the LNG liquefaction process.

Cryogenic heat exchangers play a crucial role in the LNG liquefaction process by transferring heat from the incoming natural gas to the refrigerant or mixed refrigerant. They operate at extremely low temperatures, typically below -160 degrees Celsius, and are designed to efficiently transfer heat while maintaining high thermal efficiency.

- Types: Various types of cryogenic heat exchangers are used, including plate-fin heat exchangers, spiral heat exchangers, and printed circuit heat exchangers.

- Importance: These heat exchangers help achieve the necessary temperature reduction and heat transfer required for liquefying the natural gas.

3. What are the safety considerations and emergency procedures for operating an LNG plant?

LNG plants involve handling large quantities of cryogenic LNG, making safety a top priority. Key considerations and emergency procedures include:

- Hazard identification: Identifying potential hazards such as cryogenic leaks, fire, and explosions.

- Emergency response plans: Establishing clear procedures for responding to emergencies, including evacuation, containment, and notification of relevant authorities.

- Personal protective equipment (PPE): Ensuring proper PPE use, such as cryogenic gloves, suits, and respirators.

- Training and drills: Providing regular training and conducting drills to ensure staff are prepared for emergencies.

4. How do you monitor and control the temperature and pressure of the LNG during the liquefaction process?

Monitoring and controlling temperature and pressure are critical in the LNG liquefaction process. Key measures include:

- Temperature sensors: Using thermocouples or resistance temperature detectors (RTDs) to measure temperature at various points in the process.

- Pressure gauges: Employing pressure gauges to monitor pressure throughout the system.

- Control systems: Implementing control systems that adjust process parameters, such as refrigerant flow rates and compressor speeds, to maintain desired temperature and pressure.

5. What are the maintenance requirements for LNG plant equipment, such as heat exchangers and compressors?

Maintaining LNG plant equipment is essential for safe and efficient operation. Regular maintenance includes:

- Heat exchangers: Regular cleaning and inspection of heat exchanger tubes to prevent fouling and ensure efficient heat transfer.

- Compressors: Maintenance of compressors involves periodic inspections, oil changes, and vibration monitoring to ensure proper operation.

- Preventive maintenance: Implementing a preventive maintenance program to identify potential issues and address them before they become major problems.

6. Describe the role of automation and control systems in an LNG plant.

Automation and control systems play a vital role in LNG plants, providing efficient and reliable operation. Key aspects include:

- Process control: Automated control systems monitor and adjust process parameters, such as temperature, pressure, and flow rates, to maintain optimal operating conditions.

- Safety systems: Safety systems are integrated to detect and respond to potential hazards, triggering alarms and initiating emergency shutdown procedures if necessary.

- Data acquisition and analysis: Control systems collect and analyze operating data to identify trends, optimize performance, and support decision-making.

7. What are the environmental considerations and regulations associated with LNG plant operations?

LNG plants must operate in compliance with environmental regulations to minimize their impact. Considerations include:

- Greenhouse gas emissions: Monitoring and reducing greenhouse gas emissions, such as methane and carbon dioxide, through efficient operations and leak detection systems.

- Water management: Responsible water management practices to minimize water consumption and discharge.

- Waste management: Implementing proper waste management procedures to dispose of hazardous and non-hazardous waste generated during operations.

8. How do you ensure the quality and consistency of the LNG produced at the plant?

Ensuring LNG quality and consistency is crucial. Key measures include:

- Quality control: Implementing quality control procedures, such as sampling and testing, to meet specified LNG specifications.

- Process monitoring: Continuously monitoring process parameters to identify and address any deviations that could impact LNG quality.

- Equipment calibration: Regular calibration of measuring and monitoring equipment to ensure accurate readings and reliable data.

9. Describe the challenges and opportunities in the LNG industry.

The LNG industry presents both challenges and opportunities:

- Challenges: Managing fluctuating LNG prices, ensuring reliable supply chains, and addressing environmental concerns.

- Opportunities: Growing global demand for LNG, technological advancements improving efficiency, and the potential for LNG as a cleaner fuel.

10. How do you stay up-to-date with the latest technologies and advancements in the LNG industry?

Staying current with industry developments is essential for professional growth. Key strategies include:

- Conferences and exhibitions: Attending industry conferences and exhibitions to network and learn about new technologies.

- Technical publications: Reading technical journals, articles, and white papers to stay informed on the latest advancements.

- Professional development: Pursuing professional development courses or certifications to enhance knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liquefied Natural Gas Plant Operator (LNG Plant Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liquefied Natural Gas Plant Operator (LNG Plant Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

LNG Plant Operators are responsible for the safe and efficient operation of Liquefied Natural Gas (LNG) plants. They monitor and control the plant’s equipment, perform maintenance and repairs, and ensure that the plant is operating in accordance with all applicable safety regulations.

1. Monitor and Control Plant Equipment

LNG Plant Operators use a variety of instruments and controls to monitor the plant’s equipment. They ensure that the equipment is operating within the specified parameters and make adjustments as necessary.

- Monitor pressure, temperature, and flow rates of LNG and other plant fluids.

- Operate valves, pumps, and compressors to control the flow of LNG and other fluids.

- Start and stop plant equipment as needed.

2. Perform Maintenance and Repairs

LNG Plant Operators perform regular maintenance and repairs on the plant’s equipment. They inspect equipment for signs of wear or damage and make repairs as necessary. They also perform preventive maintenance tasks to keep the equipment in good working order.

- Inspect plant equipment for signs of wear or damage.

- Make repairs to plant equipment as needed.

- Perform preventive maintenance tasks, such as cleaning and lubrication.

3. Ensure Plant Safety

LNG Plant Operators are responsible for ensuring the safety of the plant and its employees. They follow all applicable safety regulations and procedures and take steps to minimize the risk of accidents.

- Follow all applicable safety regulations and procedures.

- Take steps to minimize the risk of accidents.

- Respond to emergencies in a safe and timely manner.

Interview Tips

Preparing for an LNG Plant Operator interview is essential to increase your chances of success. Here are some tips to help you prepare:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, the role of the LNG Plant Operator, and the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and values.

- Read industry publications and news articles to learn about the LNG industry.

- Talk to people in your network who work in the LNG industry.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked in an LNG Plant Operator interview. It is helpful to practice answering these questions in advance so that you can deliver confident and well-thought-out responses.

- Tell me about your experience in the LNG industry.

- What are your strengths and weaknesses as an LNG Plant Operator?

- How do you ensure the safety of the plant and its employees?

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of the interview is a great way to show your interest in the position and the company. It also gives you an opportunity to learn more about the company and the role. Here are a few questions you could ask:

- What are the biggest challenges facing the LNG industry today?

- What are the company’s plans for growth in the future?

- What is the company’s safety record?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Liquefied Natural Gas Plant Operator (LNG Plant Operator) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.