Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Liquor Grinding Mill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

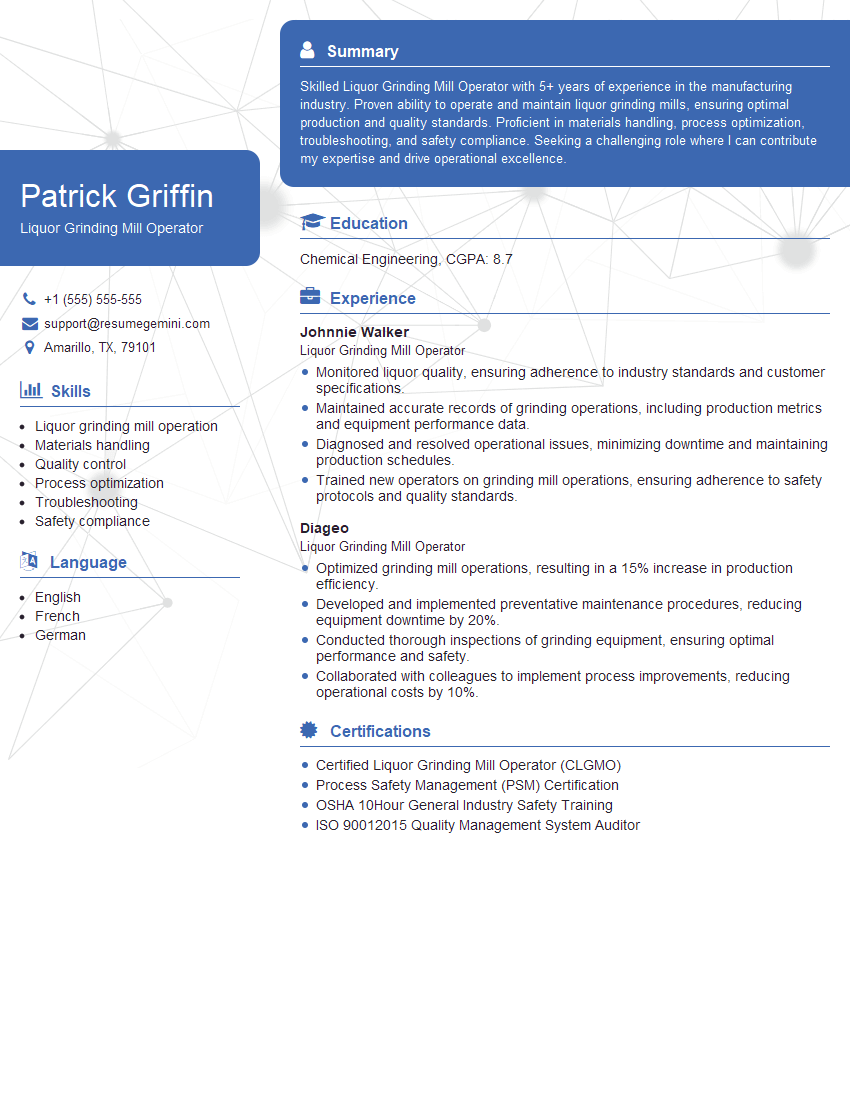

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liquor Grinding Mill Operator

1. What are the different types of liquor grinding mills and how do they operate?

- Ball mills: These mills use steel balls to grind the liquor and are commonly used in the production of paper and cement.

- Rod mills: These mills use steel rods to grind the liquor and are commonly used in the mining industry.

- Vertical mills: These mills use a rotating grinding table to grind the liquor and are commonly used in the production of glass and ceramics.

- Horizontal mills: These mills use a rotating drum to grind the liquor and are commonly used in the production of paint and ink.

2. What are the critical parameters that need to be monitored and controlled in a liquor grinding mill operation?

subheading of the answer

- Feed rate: The rate at which the liquor is fed into the mill.

- Speed of rotation: The speed at which the mill rotates.

- Grinding media: The type and size of the grinding media used.

subheading of the answer

- Temperature: The temperature of the liquor inside the mill.

- Consistency: The consistency of the liquor inside the mill.

- pH: The pH of the liquor inside the mill.

3. How do you troubleshoot a liquor grinding mill that is not producing the desired product?

- Check the feed rate: Make sure that the feed rate is correct.

- Check the speed of rotation: Make sure that the mill is rotating at the correct speed.

- Check the grinding media: Make sure that the grinding media is the correct type and size.

- Check the temperature: Make sure that the temperature of the liquor inside the mill is correct.

- Check the consistency: Make sure that the consistency of the liquor inside the mill is correct.

- Check the pH: Make sure that the pH of the liquor inside the mill is correct.

4. What are the safety precautions that must be taken when operating a liquor grinding mill?

- Wear appropriate personal protective equipment (PPE): This includes a hard hat, safety glasses, earplugs, and gloves.

- Be aware of the moving parts of the mill: Keep your hands and feet away from the rotating parts of the mill.

- Do not enter the mill while it is in operation: If you need to enter the mill, make sure that it is turned off and locked out.

- Follow all safety procedures: Make sure that you are familiar with and follow all of the safety procedures for operating the mill.

- Report any unsafe conditions: If you see any unsafe conditions, report them to your supervisor immediately.

5. What are the maintenance tasks that need to be performed on a liquor grinding mill?

- Lubricate the mill: Lubricate the mill according to the manufacturer’s instructions.

- Inspect the mill for wear and tear: Inspect the mill for any signs of wear and tear and repair or replace any damaged parts.

- Calibrate the mill: Calibrate the mill according to the manufacturer’s instructions.

- Keep the mill clean: Keep the mill clean and free of debris.

6. What are the different types of liquor grinding mill liners and how do they affect the grinding process?

- Rubber liners: Rubber liners are used to protect the mill shell from wear and tear and to reduce noise.

- Ceramic liners: Ceramic liners are used to improve the grinding efficiency and to reduce wear and tear on the grinding media.

- Metal liners: Metal liners are used to increase the grinding capacity of the mill.

7. What are the different types of liquor grinding mill drives and how do they affect the grinding process?

- Electric drives: Electric drives are used to provide power to the mill.

- Hydraulic drives: Hydraulic drives are used to provide power to the mill and to control the speed of rotation.

- Mechanical drives: Mechanical drives are used to provide power to the mill and to control the speed of rotation.

8. What are the different types of liquor grinding mill feed systems and how do they affect the grinding process?

- Gravity feed systems: Gravity feed systems use gravity to feed the liquor into the mill.

- Positive displacement feed systems: Positive displacement feed systems use a pump or other device to force the liquor into the mill.

- Vibrating feed systems: Vibrating feed systems use a vibrating feeder to feed the liquor into the mill.

9. What are the different types of liquor grinding mill discharge systems and how do they affect the grinding process?

- Gravity discharge systems: Gravity discharge systems use gravity to discharge the liquor from the mill.

- Positive displacement discharge systems: Positive displacement discharge systems use a pump or other device to force the liquor out of the mill.

- Vibrating discharge systems: Vibrating discharge systems use a vibrating feeder to discharge the liquor from the mill.

10. What are the different types of liquor grinding mill control systems and how do they affect the grinding process?

- Manual control systems: Manual control systems are used to control the mill manually.

- Automatic control systems: Automatic control systems are used to control the mill automatically.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liquor Grinding Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liquor Grinding Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Liquor Grinding Mill Operators are responsible for overseeing the operation and maintenance of liquor grinding mills. They ensure that the mill is operating efficiently and safely, and produce a product of a consistent quality.

1. Operate the mill

Liquor Grinding Mill Operators must be able to efficiently operate the mill, and maintain a consistent production rate. This requires monitoring the mill’s controls and making adjustments as needed. They must also be able to identify and troubleshoot any problems that may arise with the mill.

- Monitor the mill’s controls and make adjustments as needed.

- Identify and troubleshoot any problems that may arise with the mill.

2. Maintain the mill

Regular maintenance is essential to the safe and efficient operation of a liquor grinding mill. Liquor Grinding Mill Operators are responsible for performing this maintenance. This includes inspecting the mill’s components, lubricating moving parts, and replacing worn parts.

- Inspect the mill’s components.

- Lubricate moving parts.

- Replace worn parts.

3. Produce a product of consistent quality

Liquor Grinding Mill Operators are responsible for ensuring that the mill produces a product of consistent quality. This requires monitoring the mill’s output and making adjustments as needed to ensure that the product meets specifications. They must also be able to identify and troubleshoot any problems that may arise with the product.

- Monitor the mill’s output.

- Make adjustments as needed to ensure that the product meets specifications.

- Identify and troubleshoot any problems that may arise with the product.

4. Ensure the mill is operating safely

Safety is a top priority in any industrial setting, and liquor grinding mills are no exception. Liquor Grinding Mill Operators are responsible for ensuring that the mill is operating safely. This includes following all safety procedures, wearing appropriate personal protective equipment, and being aware of the potential hazards associated with the mill. They must also be able to identify and mitigate any safety risks that may arise.

- Follow all safety procedures.

- Wear appropriate personal protective equipment.

- Be aware of the potential hazards associated with the mill.

- Identify and mitigate any safety risks that may arise.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Take some time to learn about the company you are applying to and the position you are interviewing for. This will give you a better understanding of the company’s culture and values, and the specific requirements of the position.

- Visit the company’s website.

- Read articles about the company.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Be specific and provide examples.

- Keep your answers brief and to the point.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire.

- Be well-groomed.

- Arrive on time for your interview.

4. Be yourself and be confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

- Be genuine and authentic.

- Be confident in your abilities.

- Show the interviewer that you are passionate about the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Liquor Grinding Mill Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Liquor Grinding Mill Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.