Are you gearing up for an interview for a Lithoduplicator Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lithoduplicator Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

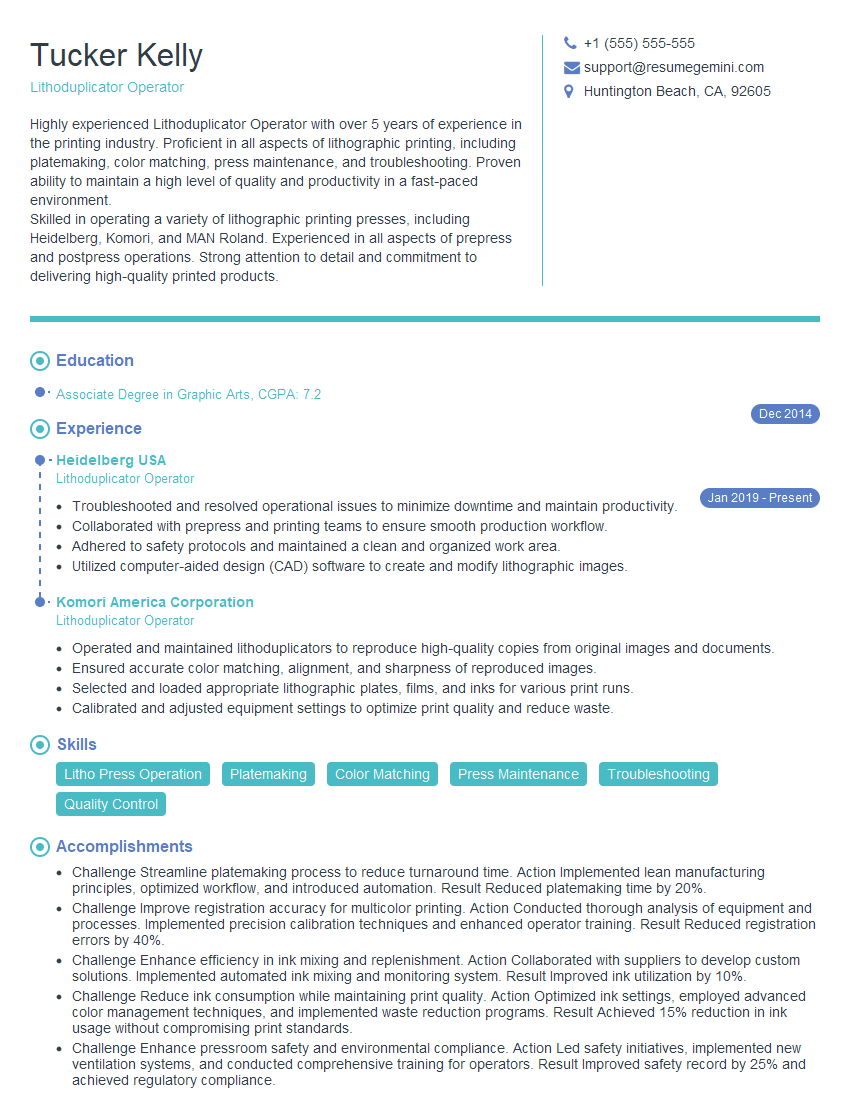

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithoduplicator Operator

1. What are the key responsibilities of a Lithoduplicator Operator?

As a Lithoduplicator Operator, my primary responsibilities include:

- Preparing and duplicating offset lithographic plates using a lithographic duplicator

- Ensuring the accuracy and quality of the duplicated plates

- Operating and maintaining the duplicator equipment

- Troubleshooting and resolving any issues that may arise during the duplication process

- Maintaining a clean and organized work area

2. How do you handle misregistration issues when duplicating plates?

Troubleshooting and Corrective Actions:

- Check the alignment of the duplicator

- Inspect the plates for any damage or defects

- Adjust the duplicator settings as needed

- If necessary, re-expose the affected plates

Preventive Measures:

- Ensure proper maintenance of the duplicator

- Use high-quality plates and materials

- Handle plates carefully to avoid damage

3. What are the different types of lithographic plates used in the duplication process?

The most common types of lithographic plates used in duplication are:

- Presensitized Plates: Pre-coated with a light-sensitive emulsion that hardens upon exposure to light

- Polymer Plates: Made of a flexible polymer material that is exposed to UV light to create the image

- Metal Plates: Typically made of aluminum or zinc, and are chemically processed to create the image

4. How do you determine the correct exposure time for duplicating plates?

The correct exposure time is crucial for producing high-quality plates. I use the following factors to determine it:

- Type and sensitivity of the plate

- Intensity of the light source

- Distance between the light source and the plate

- Required contrast and resolution

5. What are the key parameters to control for maintaining consistent plate quality?

- Exposure: Ensure accurate exposure time and intensity

- Processing: Maintain optimal temperature and chemical concentrations during plate development and finishing

- Storage: Store plates in a cool, dry environment to prevent damage

- Handling: Avoid touching the image area or exposing plates to excessive light

6. How do you troubleshoot common issues that can occur during plate duplication?

I follow a systematic approach to troubleshoot common issues:

- Identify the problem (e.g., poor image quality, misregistration)

- Check for any obvious errors in the setup or process

- Refer to the manufacturer’s guidelines or consult with a technical expert

- Implement corrective actions and verify the results

7. What safety precautions do you take while operating lithographic duplicators?

- Wear appropriate safety gear (e.g., gloves, safety glasses)

- Handle chemicals safely and dispose of them properly

- Operate equipment according to manufacturer’s instructions

- Maintain a clean and organized work area

- Be aware of potential hazards (e.g., moving parts, electrical components)

8. How do you stay updated with the latest advancements in lithographic duplication technology?

To stay current, I engage in the following practices:

- Attend industry conferences and workshops

- Read technical journals and publications

- Consult with manufacturers and suppliers

- Participate in online forums and discussions

9. What is the role of computer-to-plate (CTP) technology in lithographic duplication?

CTP technology revolutionized platemaking by eliminating the need for film and manual processing.

- Eliminates errors: Direct imaging reduces the risk of errors associated with film-based methods

- Improves efficiency: Streamlines the platemaking process, reducing production time

- Enhances quality: CTP systems produce plates with higher resolution and precision

10. How do you handle variations in paper stock during the duplication process?

To accommodate different paper stocks, I make the following adjustments:

- Plate preparation: Select the appropriate plate type and exposure settings based on the paper’s surface and absorbency

- Ink selection: Choose inks that are compatible with the paper and provide optimal adhesion

- Press adjustments: Modify printing pressure, temperature, and ink flow rate to optimize image transfer

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithoduplicator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithoduplicator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lithoduplicator Operators play a vital role in the printing industry. They are responsible for operating and maintaining lithographic duplicating machines to produce high-quality copies of original documents.

1. Machine Operation

Lithoduplicator Operators are responsible for setting up, calibrating, and operating lithographic duplicating machines. They must be able to maintain proper ink and water balance, adjust the machine to accommodate different paper types and sizes, and troubleshoot any mechanical problems that may arise.

- Set up, calibrate, and operate lithographic duplicating machines

- Ensure proper ink and water balance

- Adjust the machine to accommodate different paper types and sizes

- Troubleshoot and resolve mechanical problems

2. Document Preparation

Lithoduplicator Operators are also responsible for preparing documents for duplication. This includes collating, stapling, and trimming the documents. They must also ensure that the documents are properly aligned on the machine and that the copies are of acceptable quality.

- Collate, staple, and trim documents

- Ensure that documents are properly aligned on the machine

- Check the quality of the copies

3. Quality Control

Lithoduplicator Operators are responsible for maintaining the quality of the copies produced by their machines. They must be able to identify and correct any errors that may occur during the duplicating process. They must also maintain a clean and organized work area.

- Identify and correct errors

- Maintain a clean and organized work area

- Follow safety protocols

4. Customer Service

Lithoduplicator Operators often interact with customers to discuss their printing needs. They must be able to provide accurate information about the duplicating process and answer any questions that customers may have.

- Provide accurate information about the duplicating process

- Answer customer questions

- Resolve customer complaints

Interview Tips

Here are a few tips to help you ace your Lithoduplicator Operator interview:

1. Research the company

Before your interview, take some time to research the company you are applying to. This will show the interviewer that you are interested in the position and that you have taken the time to learn more about the company’s culture and values.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people in your network who work for the company

2. Practice your answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Use the STAR method to answer behavioral questions

- Practice answering questions about your experience, skills, and qualifications

- Be prepared to talk about your motivations for applying for the position

3. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Wear a suit or dress pants and a button-down shirt

- Make sure your shoes are clean and polished

- Avoid wearing too much jewelry or perfume

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Give yourself plenty of time to get to the interview

- If you are running late, call the interviewer to let them know

- Be prepared to wait a few minutes if the interviewer is running behind

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and authentic

- Show the interviewer your personality

- Be confident in your abilities

Next Step:

Now that you’re armed with the knowledge of Lithoduplicator Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lithoduplicator Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini