Are you gearing up for a career in Lithograph Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lithograph Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

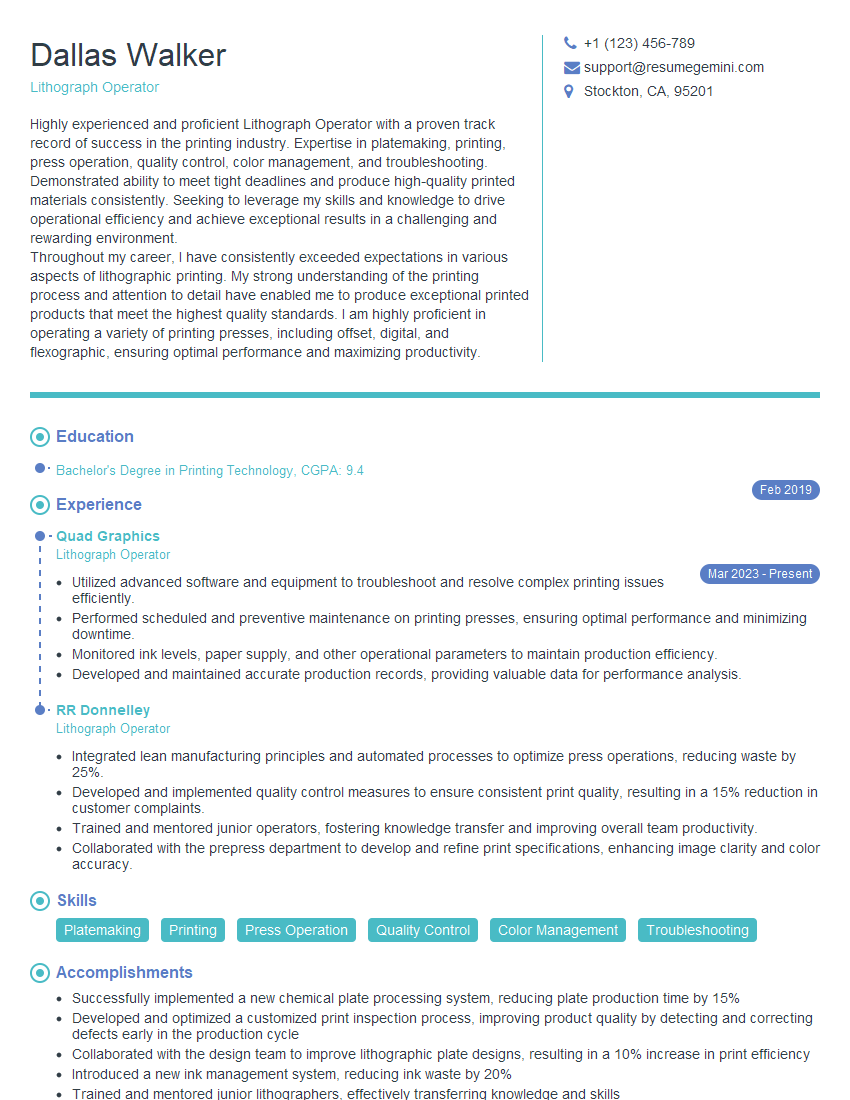

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithograph Operator

1. What are the different types of lithographic presses and their applications?

Lithographic presses can be classified into two main types based on the method of transferring the image to the printing plate:

- Offset presses: In offset printing, the image is transferred from the printing plate to a rubber roller (blanket) before being transferred to the paper. This allows for more precise image registration and higher quality prints.

- Direct presses: In direct printing, the image is transferred directly from the printing plate to the paper. This method is faster and less expensive than offset printing, but it can result in less precise image registration and lower quality prints.

2. Describe the process of creating a lithographic printing plate.

Prepress

- Prepare the original artwork.

- Create a film positive or negative.

- Expose the printing plate to the film.

Press

- Mount the printing plate on the press.

- Dampen the printing plate with water.

- Apply ink to the printing plate.

- Transfer the ink from the printing plate to the paper.

3. What are the factors that affect the quality of a lithographic print?

The quality of a lithographic print is affected by several factors, including:

- The quality of the original artwork

- The quality of the printing plate

- The quality of the press

- The skill of the press operator

- The type of paper used

4. How do you troubleshoot common lithographic printing problems?

Some common lithographic printing problems and their solutions include:

- Poor image quality: This can be caused by a variety of factors, such as a dirty printing plate, improper ink-water balance, or incorrect press settings.

- Registration problems: This can be caused by a variety of factors, such as a loose printing plate, worn gears, or incorrect press settings.

- Paper feeding problems: This can be caused by a variety of factors, such as a damaged paper feeder, incorrect paper settings, or a faulty press.

5. What are the safety precautions that must be taken when operating a lithographic press?

Lithographic presses can be dangerous if they are not operated properly. Some of the safety precautions that must be taken include:

- Wear appropriate safety clothing, including gloves, safety glasses, and a lab coat.

- Never reach into the press while it is running.

- Keep the press area clean and free of debris.

- Follow all manufacturer’s instructions for operating the press.

6. What is the role of a lithographic operator in a printing company?

A lithographic operator is responsible for operating a lithographic press to produce high-quality printed materials. Some of the duties of a lithographic operator include:

- Preparing the printing press for operation

- Loading paper into the press

- Adjusting the press settings

- Monitoring the press during operation

- Troubleshooting and resolving any problems that occur

7. What are the skills and qualifications required to be a successful lithographic operator?

To be a successful lithographic operator, you need to have the following skills and qualifications:

- A high school diploma or equivalent

- Experience operating a lithographic press

- Knowledge of lithographic printing processes

- Strong attention to detail

- Excellent problem-solving skills

8. What is the career outlook for lithographic operators?

The career outlook for lithographic operators is expected to be good over the next few years. As the demand for printed materials continues to grow, so will the demand for skilled lithographic operators.

9. What are the different types of inks used in lithographic printing?

The different types of inks used in lithographic printing include:

- Oil-based inks: Oil-based inks are made from a mixture of pigments, oils, and resins. They are durable and resistant to water and fading.

- Water-based inks: Water-based inks are made from a mixture of pigments, water, and resins. They are less durable than oil-based inks, but they are more environmentally friendly.

- UV-curable inks: UV-curable inks are made from a mixture of pigments and resins that are cured by exposure to ultraviolet light. They are very durable and resistant to water and fading.

10. What are the different types of papers used in lithographic printing?

The different types of papers used in lithographic printing include:

- Coated papers: Coated papers have a smooth, glossy surface that is ideal for reproducing high-quality images.

- Uncoated papers: Uncoated papers have a rough, matte surface that is less expensive than coated papers.

- Specialty papers: Specialty papers are designed for specific applications, such as labels, envelopes, and business cards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithograph Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithograph Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lithograph Operators are responsible for the printing of images onto various surfaces, using lithographic printing presses. They are responsible for setting up and operating the press, as well as maintaining its optimal performance. Additionally, they are responsible for maintaining the quality of the printed images, and ensuring that the printing process is completed efficiently and safely.

1. Pre-Press Activities

Lithograph operators begin by preparing the printing plates for the lithographic press. They work with prepress technicians to create the digital files that will be used to create the printing plates. These files are then transferred to the printing plates, which are used to transfer the image to the paper.

2. Press Operation

Once the printing plates are ready, the lithograph operator sets up the press and begins the printing process. They adjust the press settings to ensure that the image is printed correctly, and they monitor the press during the printing process to ensure that the images are printed to the correct specifications.

3. Post-Press Activities

After the printing process is complete, the lithograph operator removes the printed sheets from the press and inspects them for quality. They also perform finishing tasks, such as trimming, folding, and binding the printed sheets.

4. Maintenance and Repair

Lithograph operators are also responsible for maintaining and repairing the printing press. They perform routine maintenance tasks, such as cleaning and lubricating the press, and they also troubleshoot and repair any problems that may arise.

Interview Tips

Preparing for an interview for a Lithograph Operator position can be daunting, but following these tips can help you increase your chances of making a good impression and landing the job.

1. Research the Company and the Position

Before you go to an interview, it is important to do your research and learn as much as you can about the company and the specific position you are applying for. This will help you understand the company’s culture and values, and it will also help you tailor your answers to the interviewer’s questions.

2. Practice Your Answers to Common Interview Questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Come to the Interview Prepared with Questions

Asking questions at the end of the interview shows that you are interested in the position and that you have taken the time to prepare for the interview. Come to the interview with a list of questions that you would like to ask the interviewer, such as “What are the biggest challenges facing the company right now?” or “What are the opportunities for advancement within the company?”

4. Be Yourself and Be Confident

It is important to be yourself and be confident in your abilities during the interview. The interviewer wants to get to know the real you, so do not try to be someone you are not. Be honest about your skills and experience, and be confident in your ability to do the job.

Next Step:

Now that you’re armed with the knowledge of Lithograph Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lithograph Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini