Feeling lost in a sea of interview questions? Landed that dream interview for Lithographic Press Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lithographic Press Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

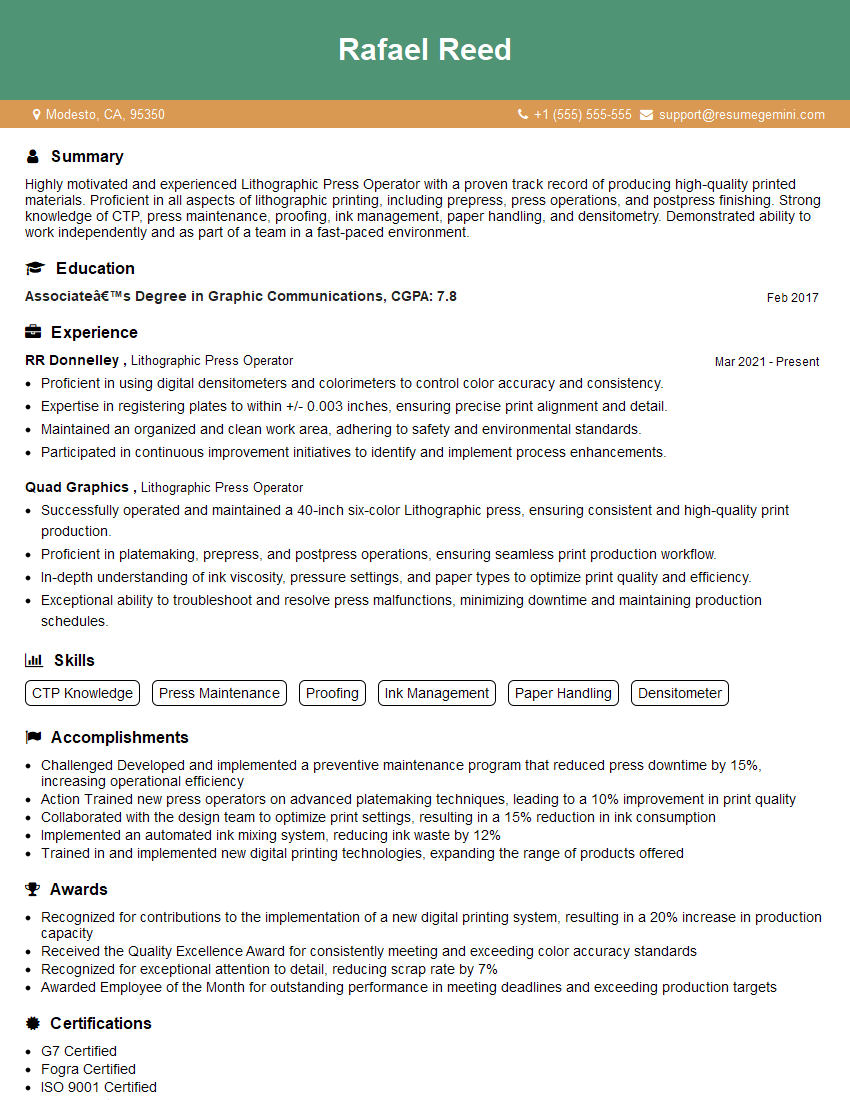

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithographic Press Operator

1. Describe the process of setting up a lithographic press.

The setup process involves several key steps:

- Plate loading: Loading the printing plate onto the press and aligning it precisely.

- Ink fountains: Setting the ink fountains to deliver the correct amount of ink in the desired colors.

- Dampening system: Adjusting the dampening system to control the amount of water applied to the non-image areas of the plate.

- Blanket adjustment: Positioning the blanket around the impression cylinder to transfer the image onto the paper.

- Pressure settings: Adjusting the impression cylinder pressure to ensure proper transfer and image quality.

2. What are the key factors that affect print quality in lithographic printing?

Print quality is influenced by various factors:

Plate preparation and processing:

- Plate resolution and etching

- Plate cleanliness and surface treatment

Press operation:

- Ink viscosity and temperature control

- Dampening balance

- Impression pressure and blanket condition

Paper characteristics:

- Surface smoothness and absorbency

- Caliper and grain direction

3. How do you troubleshoot common printing problems such as ink smearing or ghosting?

Troubleshooting printing problems requires systematic analysis:

- Ink smearing: Check ink viscosity, fountain settings, blanket condition, and impression pressure.

- Ghosting: Inspect the plate for damage or contamination, adjust the dampening system, and ensure proper plate exposure.

4. Explain the different types of printing plates used in lithographic printing.

Lithographic printing plates come in various types:

- Aluminum plates: Widely used for commercial printing due to their durability and image quality.

- Polyester plates: Known for their flexibility and suitability for high-speed printing.

- Paper plates: Used for short-run printing and prototyping.

5. How do you maintain and calibrate lithographic press equipment?

Regular maintenance is crucial:

- Equipment cleaning: Regularly cleaning ink fountains, dampening rollers, and printing blankets.

- Calibration: Using calibration tools to ensure accurate plate registration, ink flow, and dampening levels.

- Preventive maintenance: Scheduled inspections and lubrication to prevent breakdowns.

6. Describe the safety precautions that should be followed when operating a lithographic press.

- Proper attire: Wear protective clothing, gloves, and safety glasses.

- Machine guarding: Ensure that all guards and safety mechanisms are in place.

- Chemical handling: Handle inks and cleaning solutions safely according to MSDS guidelines.

- Fire prevention: Keep the press area clean and free of flammable materials.

7. How do you optimize press efficiency and minimize waste?

Optimizing efficiency and minimizing waste involves:

- Job planning: Grouping similar jobs together to reduce setup time.

- Waste reduction: Using automated waste removal systems and optimizing ink and paper usage.

- Continuous improvement: Implementing lean manufacturing principles and analyzing press performance data.

8. Explain the process of color matching in lithographic printing.

Color matching involves:

- Color measurement: Using spectrophotometers to measure and analyze colors.

- Ink mixing: Adjusting ink formulations to achieve desired colors.

- Proofing: Printing test prints to compare colors and make corrections.

9. What are the key quality control measures used in lithographic printing?

Quality control measures include:

- Visual inspection: Examining prints for errors, defects, and color accuracy.

- Densitometry: Using densitometers to measure ink density and ensure consistency.

- Registration: Verifying that print elements are aligned correctly.

10. Describe your experience in working with different types of paper in lithographic printing.

I have experience in working with a range of paper types, including:

- Offset paper: Uncoated paper commonly used for commercial printing.

- Glossy paper: Coated paper that provides a high-gloss finish.

- Specialty papers: Unique papers with textures, colors, or finishes for special applications.

I understand the different properties of each paper type and how they affect the printing process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithographic Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithographic Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lithographic Press Operator is responsible for the operation of a lithographic printing press. The following are some of the key job responsibilities:

1. Set up and operate lithographic printing press

This involves preparing the press for printing, loading paper, and adjusting the press settings. The operator must ensure that the press is properly calibrated and that the printed materials meet the customer’s specifications.

- Setting up and adjusting the lithographic printing press according to job specifications.

- Loading and unloading paper or other materials into the press.

2. Monitor printing process

The operator must monitor the printing process to ensure that the printed materials are of good quality. The operator must also make adjustments to the press as needed to ensure that the printing process is running smoothly.

- Monitoring the printing process to ensure that the printed materials meet the customer’s specifications.

- Making adjustments to the press as needed to maintain the quality of the printed materials.

3. Troubleshoot and repair printing problems

The operator must be able to troubleshoot and repair printing problems. The operator must be able to identify the cause of the problem and make the necessary repairs to get the press up and running again.

- Troubleshooting and resolving printing problems to ensure the smooth operation of the press.

- Performing routine maintenance and repairs on the printing press to ensure its longevity.

4. Maintain printing press

The operator must maintain the printing press to ensure that it is in good working order. The operator must perform regular maintenance tasks such as cleaning the press, lubricating the moving parts, and replacing worn parts.

- Performing preventive maintenance tasks to ensure the press is in optimal condition.

- Maintaining a clean and organized work area to promote efficiency and safety.

Interview Tips

Preparing for an interview can be a daunting task. However, by following these tips, you can increase your chances of success:

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the position. You can research the company’s website, social media pages, and news articles. You can also talk to people who work at the company or who have worked there in the past.

- Researching the company’s website, industry news, and social media presence to gain insights into their culture and values.

- Familiarizing yourself with the job description and identifying the key skills and experience required for the role.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the company culture. You should also make sure that your shoes are clean and that your hair is neat.

- Dressing in formal attire that is clean, pressed, and appropriate for the business environment.

- Maintaining good grooming and hygiene to project a professional and confident image.

4. Be on time

Punctuality is important for any interview. Make sure that you arrive for your interview on time, or even a few minutes early. This will show the interviewer that you are respectful of their time.

- Planning your route and transportation in advance to avoid delays.

- Arriving at the interview location on time or slightly early to demonstrate respect and professionalism.

5. Be confident

Confidence is key in any interview. Believe in yourself and your abilities. Make eye contact with the interviewer, speak clearly and concisely, and answer questions honestly and confidently.

- Maintaining a positive attitude and projecting confidence throughout the interview.

- Asking thoughtful questions to demonstrate your interest and engagement.

Next Step:

Now that you’re armed with the knowledge of Lithographic Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lithographic Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini