Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lithographic Proofer Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

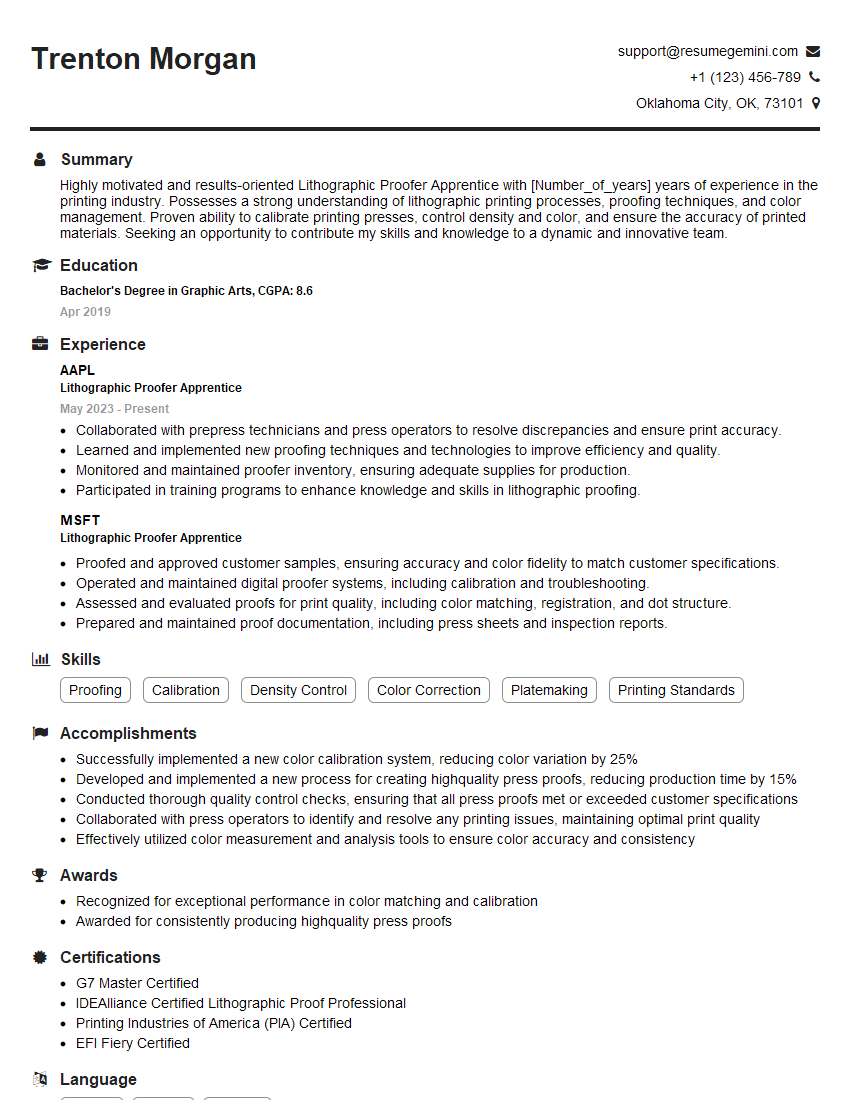

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithographic Proofer Apprentice

1. Describe the process of color correction in lithographic proofing?

Color correction in lithographic proofing involves adjusting the color balance and density of the printed image to match the specified target values. It typically involves the following steps:

- Creating a reference print from the original artwork

- Measuring the color values of both the print and the proof using a spectrophotometer

- Calculating the necessary color adjustments based on the measured values

- Applying the adjustments to the proof using a color correction software

- Printing a new proof and repeating the process until the desired color match is achieved

2. What is the difference between a digital and a conventional lithographic proof?

Digital lithographic proof

- Created directly from digital files using a digital press

- Faster and more economical for short runs and quick turnaround times

- May have limitations in terms of color accuracy and precision compared to conventional proofs

Conventional lithographic proof

- Produced by transferring an image from a printing plate to paper using traditional lithographic printing techniques

- Offers higher color accuracy and fidelity, particularly for complex and high-quality prints

- More time-consuming and expensive compared to digital proofs

3. What are the critical factors to consider when choosing a lithographic proof substrate?

When selecting a lithographic proof substrate, the following factors should be taken into account:

- Surface texture and smoothness: Affects the print quality and the ability to accurately reproduce fine details

- Opacity and brightness: Influences the overall appearance and contrast of the printed image

- Coating type: Different coatings can enhance color accuracy, water resistance, and durability

- Weight and thickness: Affects the handling and durability of the proof

- Compatibility: The substrate should be compatible with the specific printing process and inks being used

4. Explain the purpose and importance of using a densitometer in lithographic proofing?

A densitometer is a device used to measure the optical density of a printed image. It plays a crucial role in lithographic proofing by:

- Quantifying the amount of ink deposited on the paper

- Evaluating the color intensity and contrast of the printed image

- Ensuring consistency and accuracy in color reproduction by comparing measurements to pre-defined standards

- Determining the optimal printing conditions to achieve the desired print quality

5. What are the common defects or issues that can occur during lithographic proofing, and how can they be prevented or corrected?

Common defects in lithographic proofing include:

- Slurring: Image distortion due to improper plate alignment or press settings

- Dot bridging: Ink dots merging together, resulting in loss of detail

- Tinting: Unintentional color cast or hue on the proof

- Ghosting: Secondary images or faint impressions appearing on the proof

- Bronzing: Metallic sheen or discoloration on the printed surface

These issues can be prevented or corrected by:

- Ensuring proper equipment maintenance and calibration

- Optimizing printing conditions and ink-water balance

- Using high-quality materials and substrates

- Implementing quality control measures throughout the proofing process

6. Describe the role of a lithographic proofer in the prepress workflow?

A lithographic proofer is responsible for producing accurate and high-quality proofs that accurately represent the final printed product. Their roles within the prepress workflow include:

- Preparing substrates and printing plates

- Operating lithographic proofing presses

- Performing color correction and adjustments

- Evaluating and assessing the quality of proofs

- Collaborating with graphic designers, printers, and clients to ensure satisfaction

7. What are the key skills and qualities required to be a successful lithographic proofer apprentice?

To excel as a lithographic proofer apprentice, the following skills and qualities are essential:

- Technical proficiency: Understanding of lithographic printing principles, color theory, and proofing techniques

- Attention to detail: Meticulous and precise in observing and assessing print quality

- Problem-solving abilities: Identifying and resolving issues that may arise during proofing

- Communication skills: Effectively communicating with colleagues, clients, and other stakeholders

- Teamwork and collaboration: Working harmoniously with others in a fast-paced environment

8. How do you stay updated with the latest advancements and trends in lithographic proofing technology?

To stay abreast of industry advancements, I engage in the following practices:

- Attending industry conferences and workshops

- Reading trade publications and technical articles

- Seeking training and certification opportunities

- Networking with professionals in the field

- Exploring online resources and forums

9. Can you provide an example of a complex or challenging proof that you successfully handled, and how you approached it?

Recently, I encountered a complex proofing project involving a high-end art reproduction. The original artwork contained intricate details and subtle color gradients. To ensure the proof accurately represented the original, I:

- Consulted with the graphic designer to understand their vision and requirements

- Carefully prepared the substrate and printing plates

- Performed multiple rounds of color correction and adjustments using advanced software

- Collaborated with the printer to optimize press settings and ink-water balance

- Produced several proofs for evaluation and fine-tuning

Through meticulous attention to detail and a collaborative approach, I successfully produced a proof that met the client’s expectations and captured the essence of the original artwork.

10. Why are you interested in becoming a lithographic proofer apprentice at our company specifically?

- Company reputation: Your company is renowned for its commitment to quality and innovation in the printing industry.

- State-of-the-art equipment: I am eager to learn and work with the advanced lithographic proofing technologies available at your facility.

- Experienced team: I believe I can benefit greatly from the knowledge and expertise of your experienced proofers.

- Training and development opportunities: I am keen on pursuing professional growth and development through your company’s training programs.

- Career advancement: I am confident that my skills and dedication will make me a valuable asset to your team, and I am excited about the potential for career advancement within your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithographic Proofer Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithographic Proofer Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lithographic Proofer Apprentice assists in the preparation and proofing of lithographic plates used in the printing process. Key responsibilities include:

1. Plate Preparation

Assists in cleaning, graining, and sensitizing lithographic plates.

2. Proofing

Assists in operating proofing presses to produce proofs from lithographic plates.

- Monitors the proofing process and makes adjustments as needed.

- Evaluates the quality of proofs and identifies any defects.

3. Plate Inspection

Inspects lithographic plates for defects and makes corrections as necessary.

- Uses a variety of tools and techniques to identify and repair defects.

- Ensures that plates meet quality standards.

4. Other Duties

Performs other duties as assigned, such as:

- Maintaining a clean and organized work area.

- Assisting in the loading and unloading of printing presses.

- Following safety procedures and regulations.

Interview Tips

To ace the interview for a Lithographic Proofer Apprentice position, consider the following tips:

1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the job.

2. Prepare for Common Interview Questions

Practice answering common interview questions, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Highlight Relevant Experience and Skills

In your resume and during the interview, emphasize any relevant experience or skills you have that relate to the job responsibilities. This may include experience in printing, platemaking, or quality control.

- For example, if you have experience using proofing presses, be sure to mention this in your resume and highlight your skills in operating and maintaining the equipment.

4. Be Enthusiastic and Professional

During the interview, be enthusiastic about the opportunity and demonstrate your professionalism. Dress appropriately, arrive on time, and maintain a positive attitude throughout the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lithographic Proofer Apprentice, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lithographic Proofer Apprentice positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.