Are you gearing up for a career in Lithographic Stripper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lithographic Stripper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

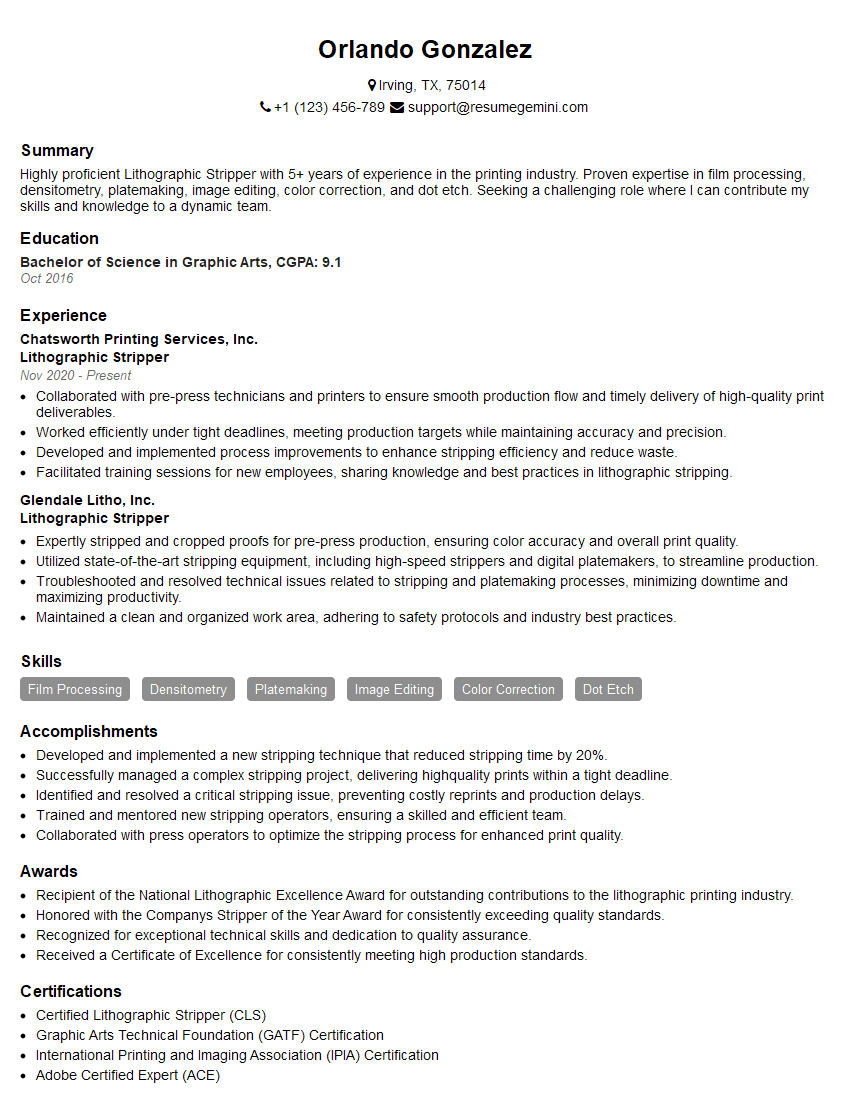

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithographic Stripper

1. Which chemicals are used in lithographic stripping and what are their functions?

- Positive Photoresist: Removes photoresist exposed to UV light, leaving the unexposed areas protected.

- Negative Photoresist: Removes unexposed photoresist, leaving the exposed areas protected.

- Stripper Solution: Breaks down the bond between photoresist and substrate, enabling its removal.

2. Describe the process of stripping photoresist using a positive photoresist.

Pre-Cleaning

- Remove any surface contaminants using a solvent cleaner.

Stripping

- Apply positive photoresist stripper solution to the surface.

- Agitate the solution to facilitate resist removal.

- Rinse the surface thoroughly with water or a developer solution.

Post-Cleaning

- Clean the surface again with solvent cleaner to remove any residual stripper.

3. What safety precautions should be taken when working with lithographic stripping chemicals?

- Wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and a lab coat.

- Ensure proper ventilation to prevent inhalation of chemical vapors.

- Handle chemicals according to their safety data sheets (SDSs) and dispose of them properly.

4. What are the common defects that can occur during lithographic stripping?

- Incompletely Removed Photoresist: Occurs when the stripping process is not optimized or the solution becomes exhausted.

- Substrate Damage: Can result from improper cleaning techniques or excessive exposure to stripping chemicals.

- Haze or Residue: Caused by insufficient rinsing or the presence of contaminants.

5. How do you determine the optimal stripping time for a given photoresist?

- Refer to the photoresist manufacturer’s recommendations.

- Conduct small-scale tests with varying stripping times to identify the shortest duration that effectively removes the resist without damaging the substrate.

6. What is the difference between a wet lithographic stripper and a dry lithographic stripper?

- Wet Stripper: Uses chemical solutions to dissolve and remove photoresist.

- Dry Stripper: Uses plasma or UV light to volatilize and remove photoresist.

7. Describe the role of surfactant in lithographic stripping solutions.

- Lowers the surface tension of the solution.

- Enhances the wetting and penetration of the solution into the photoresist.

- Helps remove contaminants and residue from the substrate.

8. What is the purpose of using a developer solution in lithographic stripping?

- Stops the stripping process and neutralizes any remaining stripper chemicals.

- Improves the removal of photoresist residue.

- Conditions the substrate for subsequent processes.

9. How do you dispose of spent lithographic stripping chemicals?

- Follow the SDS guidelines and local regulations.

- Neutralize the chemicals if necessary.

- Dispose of chemicals in a licensed hazardous waste facility.

10. What are the advantages and disadvantages of using a spray stripper versus an immersion stripper?

Spray Stripper

- Advantages: Faster, more efficient, smaller chemical volume required.

- Disadvantages: Potential for overspray, requires specialized equipment.

Immersion Stripper

- Advantages: More uniform stripping, less likely to damage substrate.

- Disadvantages: Slower, requires larger chemical volume, more difficult to control stripper life.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithographic Stripper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithographic Stripper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lithographic Stripper is an essential part of the printing process. They are responsible for preparing printing plates by removing the light-sensitive coating from non-image areas.

1. Pre-press Preparation

The Lithographic Stripper’s role begins with pre-press preparation, where they:

- Review and analyze artwork and technical specifications to ensure adherence to print quality standards.

- Operate a computer-aided design (CAD) system to create and output positive or negative films.

- Prepare and calibrate film processors to ensure optimal exposure and development of photographic materials.

2. Plate Stripping

The core responsibility of a Lithographic Stripper is plate stripping, involving the following tasks:

- Apply a light-sensitive coating to aluminum or polyester plates, creating a temporary protective layer.

- Exposing the coated plates to light through the prepared films, transferring the image to the plate.

- Developing the exposed plates using chemical solutions to remove the unexposed coating, leaving the image areas.

3. Post-Stripping Finishing

After plate stripping, the Lithographic Stripper performs post-stripping finishing tasks, including:

- Inspecting developed plates for defects, such as scratches or pinholes, and making necessary repairs.

- Cleaning and gumming plates to remove residual chemicals and enhance ink adhesion during printing.

- Preparing plates for storage or delivery to the press room for printing.

4. Maintenance and Quality Control

To ensure efficient and high-quality production, Lithographic Strippers are also responsible for:

- Maintaining and calibrating plate stripping equipment, including film processors, exposure units, and developing machines.

- Monitoring and controlling chemical solutions used in the stripping process to maintain consistent results.

- Adhering to safety and environmental regulations related to the handling and disposal of chemicals.

Interview Tips

Preparing for a Lithographic Stripper interview requires research, practice, and showcasing your skills and experience. Here are some tips to help you ace your interview:

1. Research the Company and the Role

Thoroughly research the company’s values, industry standing, and the specific requirements of the Lithographic Stripper role. This knowledge will enable you to tailor your answers to the interviewer’s questions and demonstrate your interest in the position.

2. Highlight Your Technical Expertise

Emphasize your proficiency in plate stripping techniques, including exposure, development, and post-processing. Mention your experience in operating CAD systems and your understanding of pre-press preparation. Provide specific examples of projects where you successfully produced high-quality printing plates.

3. Showcase Your Attention to Detail

Lithographic Strippers must have a keen eye for detail. Highlight your ability to inspect plates for defects and your commitment to maintaining a clean and organized work area. Share instances where you identified and resolved plate defects, ensuring the production of flawless prints.

4. Demonstrate Problem-Solving Abilities

The interview may include questions about troubleshooting. Prepare to discuss how you approach and solve common issues that arise during the stripping process. Explain your analytical approach and your experience in resolving technical challenges to achieve desired results.

5. Prepare for Questions about Safety and Regulations

As a Lithographic Stripper, you must adhere to safety protocols and environmental regulations. Be ready to answer questions about your knowledge of handling and disposing of chemicals. Discuss your commitment to following established safety guidelines and your understanding of best practices.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lithographic Stripper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.