Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lithography Contact Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

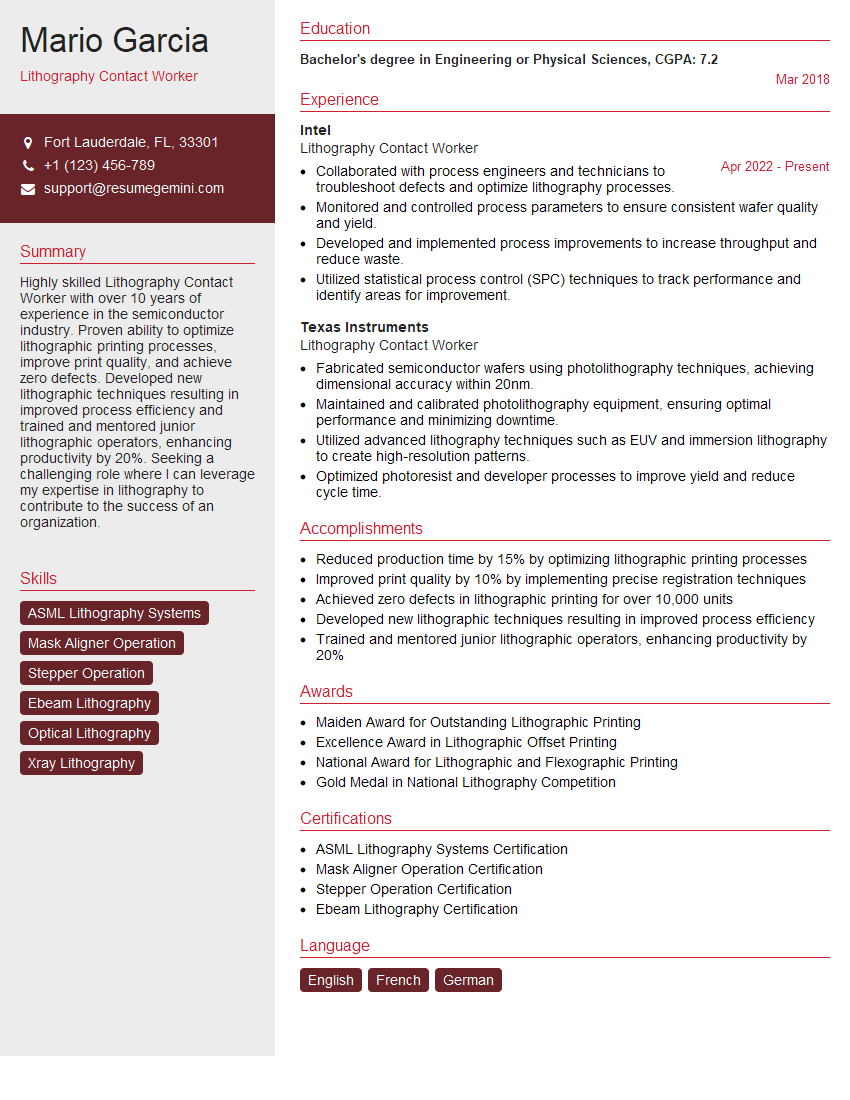

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithography Contact Worker

1. What are the key steps involved in the lithography contact printing process?

The key steps involved in lithography contact printing process are:

- Substrate preparation

- Application of photoresist

- Exposure to ultraviolet light

- Development

- Hardening or curing

2. Describe the different types of photoresists used in lithography.

Positive photoresists

- Become soluble in developer after exposure to UV light

- Used to create positive images (areas exposed to UV light are removed during development)

Negative photoresists

- Become insoluble in developer after exposure to UV light

- Used to create negative images (areas exposed to UV light remain after development)

3. Explain the purpose of a mask in lithography.

A mask in lithography is a patterned material that blocks or allows the passage of UV light. It is used to transfer the desired pattern onto the photoresist-coated substrate.

4. Describe the different types of lithography exposure systems.

- Contact exposure

- Proximity exposure

- Projection exposure

- E-beam lithography

- Laser lithography

5. What are the factors that affect the resolution of a lithography process?

- Wavelength of the exposure light

- Numerical aperture of the exposure system

- Characteristics of the photoresist

- Substrate properties

6. How do you measure and control the thickness of a photoresist film?

The thickness of a photoresist film can be measured using a variety of techniques, including ellipsometry, interferometry, and profilometry. It can be controlled by adjusting the viscosity of the photoresist, the spin speed, and the baking time and temperature.

7. What are the common defects that can occur during lithography and how can they be prevented?

Common defects in lithography include:

- Edge bead

- Pinhole

- Scum

- Bridging

- Cracking

These defects can be prevented by optimizing the process parameters, such as exposure dose, development time, and post-exposure bake temperature.

8. How do you troubleshoot a lithography process?

Lithography process troubleshooting involves identifying the source of the problem and implementing corrective actions. Some common troubleshooting steps include:

- Checking the mask for defects

- Verifying the exposure dose and development time

- Inspecting the substrate for contamination

- Analyzing the photoresist film thickness and uniformity

9. What are the safety precautions that should be observed when working with lithography chemicals?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Handle chemicals in a well-ventilated area.

- Avoid contact with skin and eyes.

- Dispose of chemicals properly according to local regulations.

10. How do you stay updated on the latest advances in lithography technology?

- Attend industry conferences

- Read technical journals and articles

- Participate in online forums and discussion groups

- Network with other lithography professionals

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithography Contact Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithography Contact Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lithography Contact Workers play a crucial role in the fabrication of semiconductor devices. Their primary responsibilities include:

1. Pre-exposure Procedures

Involves preparing the wafers for exposure by cleaning and preparing the mask and reticle.

- Clean wafers and substrates using chemicals and solvents.

- Inspect and align wafers and substrates to ensure optimal exposure.

- Mount masks and reticles onto the exposure tool.

2. Exposure Operations

Conducts exposure operations to transfer patterns from masks and reticles onto wafers.

- Align and expose wafers to ultraviolet or extreme ultraviolet light.

- Control exposure parameters such as dosage and timing.

- Optimize exposure processes to minimize defects and ensure pattern fidelity.

3. Post-exposure Procedures

Involves developing and etching the exposed wafers to create the desired patterns.

- Develop exposed wafers using chemical solutions.

- Etch wafers using plasma or wet etching techniques.

- Inspect and analyze wafers to ensure pattern integrity and quality.

4. Equipment Maintenance

Maintains and calibrates lithography equipment to ensure optimal performance.

- Clean and adjust exposure tools and mask aligners.

- Perform regular maintenance and calibration procedures.

- Troubleshoot and resolve equipment issues.

Interview Tips

To ace your interview for a Lithography Contact Worker position, consider the following preparation tips:

1. Technical Expertise

Showcase your in-depth knowledge of lithography processes, including pre-exposure, exposure, and post-exposure procedures. Prepare to discuss:

- Principles of photolithography and photoresist exposure.

- Exposure equipment and their functions.

- Techniques for exposure optimization and defect reduction.

2. Equipment Knowledge

Demonstrate your familiarity with lithography equipment and their maintenance. Emphasize your experience in:

- Installation, calibration, and troubleshooting of exposure tools.

- Preventive maintenance procedures to ensure equipment uptime.

- Understanding of safety protocols related to lithography equipment.

3. Process Control and Optimization

Highlight your skills in process control and optimization. Describe your experience in:

- Monitoring and controlling exposure parameters to achieve desired pattern fidelity.

- Implementing quality control measures to minimize defects and ensure process stability.

- Participate in continuous improvement projects to enhance lithography processes.

4. Communication and Teamwork

Emphasize your ability to communicate effectively and work collaboratively. Describe your experience in:

- Communicating technical information to engineers and operators.

- Collaborating with other team members to resolve issues and improve processes.

- Maintaining a positive and professional attitude in a fast-paced environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lithography Contact Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.