Feeling lost in a sea of interview questions? Landed that dream interview for Lithostripper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lithostripper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

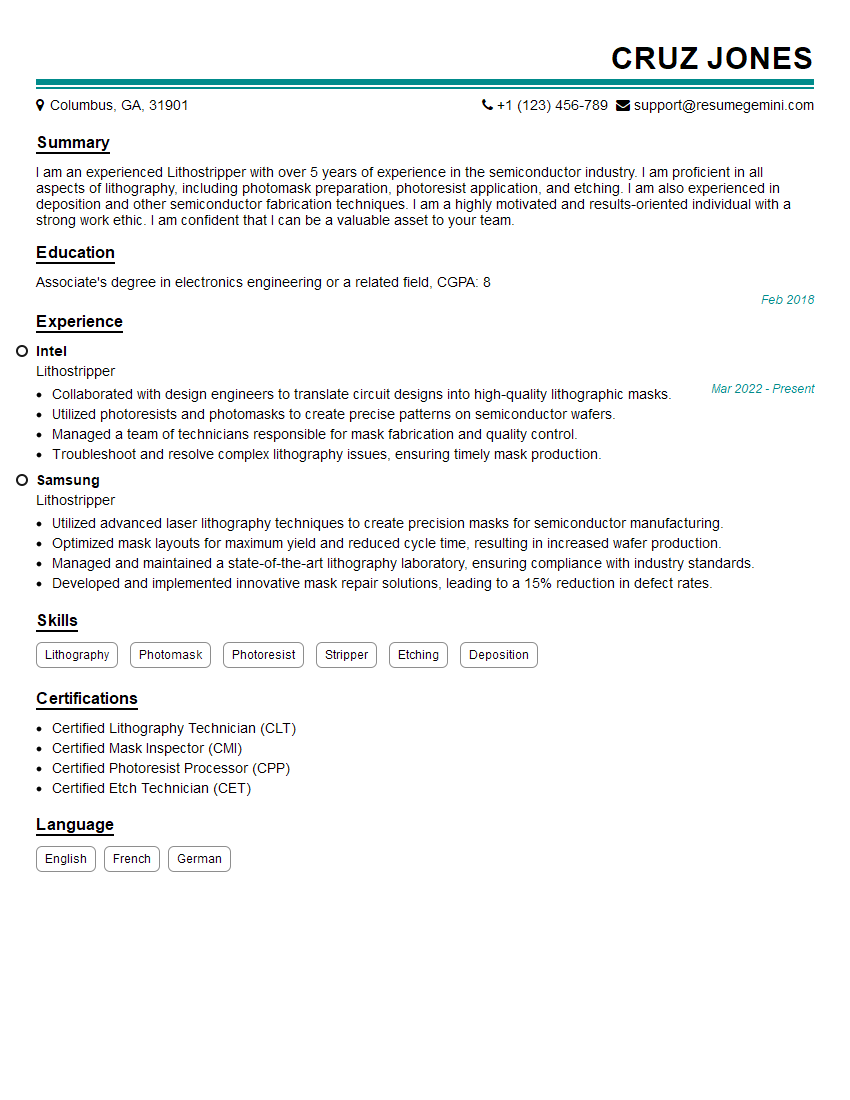

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithostripper

1. What are the key lithographic processes involved in semiconductor manufacturing?

- Photolithography

- Electron beam lithography

- X-ray lithography

2. Describe the steps involved in photolithography and explain the role of a lithostripper in the process.

- Mask design

- Wafer preparation

- Photoresist deposition

- Exposure to ultraviolet light

- Development

Role of a lithostripper:

- Strips the photoresist after exposure and development

- Leaves the desired pattern on the wafer

3. What are the different types of lithostrippers?

- Wet lithostrippers

- Dry lithostrippers

- Plasma lithostrippers

4. Explain the advantages and disadvantages of wet lithostrippers.

Advantages:

- Low cost

- High throughput

- Good for removing thick photoresist

Disadvantages:

- Can damage the wafer surface

- Requires extensive waste treatment

5. Describe the operation of a dry lithostripper.

- Uses a reactive gas (e.g., oxygen) to etch away the photoresist

- More precise than wet lithostrippers

- Less likely to damage the wafer surface

6. What are the safety precautions that need to be taken when working with lithostrippers?

- Wear protective clothing (gloves, mask, etc.)

- Ensure proper ventilation

- Follow all manufacturer instructions

7. What are the trends in lithography technology?

- Extreme ultraviolet lithography (EUV)

- Nanoimprinting lithography

- Directed self-assembly

8. Explain the challenges of controlling lithography processes at the nanoscale.

- Defects in materials and processes

- Edge roughness and line width variations

- Resist collapse

9. What are the applications of lithography in semiconductor manufacturing?

- Creating transistors and other electronic devices

- Patterning interconnects

- Fabricating sensors and displays

10. Describe your experience with lithography processes and equipment.

Provide specific details about your work experience, including the types of lithography processes used, the equipment operated, and the challenges encountered.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithostripper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithostripper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lithostripper carries out the initial stages of semiconductor fabrication by stripping photoresist from a semiconductor wafer. Their key responsibilities include:1. Lithographic Techniques

Utilizing photolithography techniques to transfer circuit patterns onto semiconductor wafers.

- Employing mask aligners or steppers to expose photoresist to ultraviolet light.

- Developing and etching the exposed photoresist to create circuit patterns.

2. Photoresist Handling

Managing the application, exposure, and removal of photoresist throughout the lithographic process.

- Applying photoresist onto wafers using spin coaters or other deposition methods.

- Controlling photoresist thickness and uniformity to ensure proper pattern formation.

3. Equipment Operation and Maintenance

Operating and maintaining lithographic equipment, including mask aligners, steppers, and developers.

- Performing routine maintenance and calibration to ensure equipment accuracy and reliability.

- Troubleshooting and resolving equipment malfunctions to minimize downtime.

4. Process Optimization

Continuously improving lithographic processes to enhance yield and reduce defects.

- Conducting experiments to optimize process parameters such as exposure dose, development time, and etch conditions.

- Analyzing process data to identify areas for improvement and implement corrective actions.

Interview Tips

To ace an interview for a Lithostripper position, consider the following tips:1. Research the Company and Role

- Review the company’s website, annual reports, and industry news to gain insights into its business.

- Thoroughly read the job description to understand the specific requirements and expectations of the role.

2. Highlight Your Technical Skills

- Showcase your proficiency in photolithography techniques, including mask alignment, exposure, and development.

- Demonstrate your knowledge of photoresist handling, equipment operation, and process optimization.

- Quantify your accomplishments and provide specific examples to illustrate your capabilities.

3. Emphasize Your Problem-Solving Abilities

- Highlight your experience in troubleshooting and resolving lithographic equipment issues.

- Describe how you have identified and addressed process defects to improve yield.

- Emphasize your analytical and logical thinking skills, which are essential for diagnosing and solving problems.

4. Communicate Your Improvement Mindset

- Express your eagerness to learn and continuously improve your lithographic processes.

- Share examples of how you have sought feedback, conducted experiments, and implemented process enhancements.

- Demonstrate your commitment to staying abreast of industry trends and best practices.

5. Prepare for Common Interview Questions

- Prepare answers to common interview questions related to lithography, such as:

- Describe the steps involved in a typical lithographic process.

- How do you control the thickness and uniformity of photoresist?

- What techniques do you use to troubleshoot equipment malfunctions?

Next Step:

Now that you’re armed with the knowledge of Lithostripper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lithostripper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini