Are you gearing up for an interview for a Loading Unit Tool Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Loading Unit Tool Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

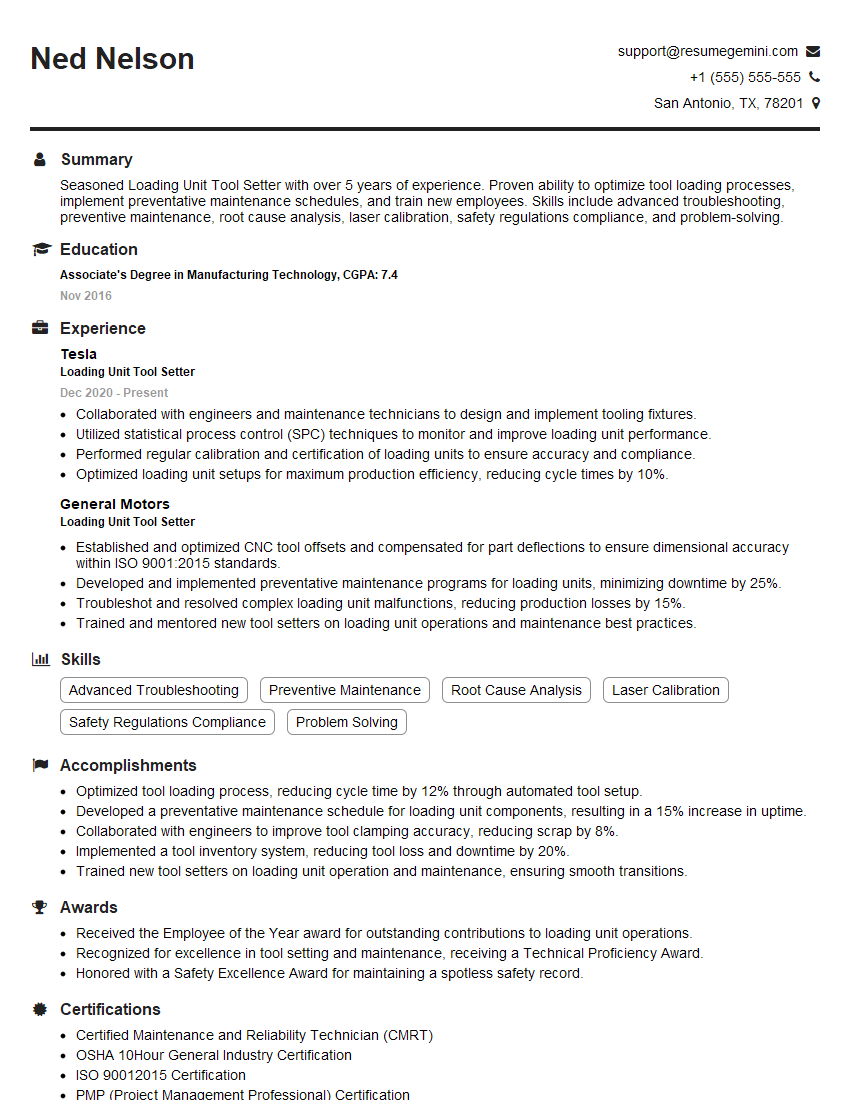

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Loading Unit Tool Setter

1. What are the different types of loading unit tools that you’ve worked with?

In my previous role, I had the opportunity to work with a variety of loading unit tools, including:

- Automatic tool changers (ATCs)

- Manual tool changers (MTCs)

- Turrets

- Disc magazines

2. What are the key factors to consider when selecting a loading unit tool?

Factors related to the machine and process:

- Machine capacity and spindle speed

- Number of tools required

- Type of material being processed

- Required cycle time

Factors related to the tool itself:

- Tool geometry and size

- Tool material

- Tool life

- Cost

3. What are the different types of tool offsets and when are they used?

The different types of tool offsets are:

- Wear offset: Compensates for tool wear

- Length offset: Compensates for tool length variation

- Radius offset: Compensates for tool radius variation

- Diameter offset: Compensates for tool diameter variation

These offsets are used to ensure that the cutting tool is positioned accurately in relation to the workpiece, regardless of any variations in the tool.

4. Describe the procedure for setting tool offsets on a CNC machine.

- Jog the machine to the desired reference point.

- Touch the tool to the reference point using a dial indicator or other measuring device.

- Enter the measured value into the machine’s tool offset table.

- Repeat the procedure for all other tools.

5. What are the different methods for measuring tool wear?

- Visual inspection

- Micrometer

- Tool wear sensor

- Cutting force monitoring

6. What are the common causes of tool breakage?

- Excessive tool wear

- Incorrect tool geometry

- Improper tool installation

- Excessive cutting forces

- Machine vibration

7. What are the different types of tool coatings and what are their benefits?

- Titanium nitride (TiN): Increased hardness and wear resistance

- Titanium aluminum nitride (TiAlN): Improved cutting performance and tool life

- Zirconium nitride (ZrN): Excellent high-temperature performance

- Diamond-like carbon (DLC): Ultra-low friction and wear resistance

8. What are the different types of cutting fluids and what are their applications?

- Soluble oil: General-purpose cutting fluid

- Semi-synthetic cutting fluid: Improved cooling and lubrication

- Synthetic cutting fluid: Excellent performance in high-speed machining

- Neat cutting oil: Used for heavy-duty machining

9. What are the different types of machine tool accessories and what are their functions?

- Tool holders: Hold and secure cutting tools

- Collets: Grip and hold round tools

- Arbors: Support and align cutting tools

- Boring bars: Used for boring operations

- Vises: Hold and secure workpieces

10. What are the safety precautions that should be taken when working with loading unit tools?

- Wear appropriate personal protective equipment (PPE)

- Inspect tools for damage before use

- Follow proper lifting techniques

- Be aware of moving machinery

- Never operate a machine under the influence of drugs or alcohol

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Loading Unit Tool Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Loading Unit Tool Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Loading Unit Tool Setters are highly skilled professionals responsible for the critical task of maintaining and troubleshooting production equipment in manufacturing facilities. They ensure that machines operate efficiently and meet production targets, contributing significantly to overall productivity and quality control.

1. Set Up and Adjust Loading Units

A primary responsibility is setting up and adjusting loading units, including robots, conveyors, and other automated systems. They meticulously align, calibrate, and troubleshoot these units to ensure seamless integration with production processes.

- Ensure precision alignment and calibration of loading units

- Trouble-shoot and resolve mechanical or electrical malfunctions

2. Optimize Production Processes

Tool Setters analyze production processes and identify areas for improvement. They optimize loading unit settings to maximize efficiency, reduce cycle times, and increase throughput.

- Monitor production data and identify bottlenecks

- Adjust loading unit parameters to improve process efficiency

3. Maintain and Repair Loading Units

They perform routine maintenance and repairs on loading units, ensuring optimal performance and preventing breakdowns. They also monitor equipment conditions and perform preventive maintenance tasks to extend the lifespan of the units.

- Lubricate, clean, and inspect loading units regularly

- Replace worn or damaged components to maintain functionality

4. Train and Supervise Operators

Tool Setters often train and supervise loading unit operators, ensuring they understand proper operating procedures and safety protocols. They provide technical guidance and support, fostering a productive and efficient work environment.

- Train operators on loading unit operation and maintenance

- Provide ongoing support and technical assistance

Interview Tips

To ace an interview for a Loading Unit Tool Setter position, it’s crucial to prepare thoroughly and showcase your skills and experience effectively.

1. Research the Company and Position

Research the company’s industry, products, and culture to demonstrate your interest and understanding. Thoroughly review the job description to grasp the specific requirements and responsibilities.

- Visit the company’s website and social media pages

- Read industry-related articles and news to stay up-to-date

2. Highlight Your Technical Skills

Emphasize your technical expertise in loading unit operation, maintenance, and troubleshooting. Provide specific examples of your experience in setting up, adjusting, and repairing loading units.

- Quantify your accomplishments using metrics and data

- Discuss your knowledge of specific loading unit systems and technologies

3. Showcase Your Process Optimization Abilities

Highlight your ability to analyze and optimize production processes. Explain how you identified bottlenecks and implemented solutions to improve efficiency and reduce cycle times.

- Share examples of successful process optimization projects

- Discuss your understanding of lean manufacturing principles and continuous improvement

4. Emphasize Your Training and Leadership Skills

If applicable, mention your experience in training and supervising loading unit operators. Explain how you effectively transferred knowledge and fostered a supportive work environment.

- Describe your training methods and the positive outcomes achieved

- Discuss your leadership style and how it contributed to team success

5. Prepare Industry-Specific Questions

Prepare industry-specific questions to demonstrate your knowledge and interest in the field. Ask about the company’s production challenges, new technologies in loading unit systems, or ongoing automation initiatives.

- Show that you are up-to-date with industry trends and best practices

- Engage the interviewer in a meaningful conversation

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Loading Unit Tool Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!