Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lockstitch Lining Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

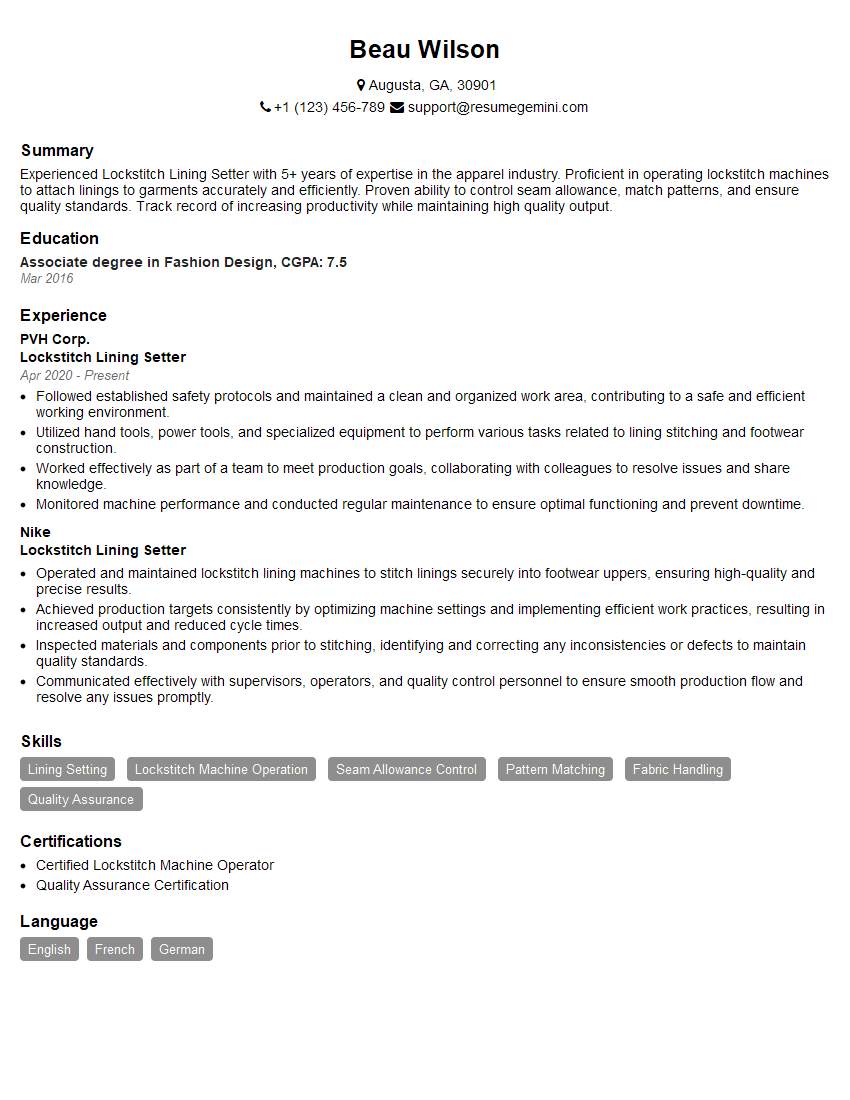

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lockstitch Lining Setter

1. What are the different types of lockstitch machines used for lining setting, and what are their key features?

There are two main types of lockstitch machines used for lining setting: single-needle and double-needle. Single-needle machines are used for setting linings in lightweight fabrics, while double-needle machines are used for setting linings in heavier fabrics. Some key features of lockstitch machines include:

- Needle type: Single-needle machines use a single needle, while double-needle machines use two needles.

- Stitch type: Lockstitch machines create a stitch that is interlocked, making it very strong and durable.

- Speed: Lockstitch machines can sew at high speeds, making them efficient for production.

2. What are the different types of lining fabrics used, and what are their properties?

There are a variety of lining fabrics used, each with its own unique properties. Some of the most common types of lining fabrics include:

Acetate

- Soft and smooth

- Wrinkle-resistant

- Dyes easily

Bemberg

- Similar to silk

- Soft and luxurious

- Good moisture absorption

Cotton

- Natural fiber

- Breathable and comfortable

- Durable and wrinkle-resistant

3. What are the different techniques used for setting linings, and when is each technique most appropriate?

There are two main techniques used for setting linings: hand sewing and machine sewing. Hand sewing is typically used for delicate fabrics or for garments that require a high level of precision. Machine sewing is more efficient and can be used for a wider range of fabrics. The most appropriate technique for setting a lining will depend on the fabric, the garment, and the desired results.

4. What are the quality standards for setting linings, and how do you ensure that your work meets these standards?

The quality standards for setting linings vary depending on the industry and the specific garment. However, some general quality standards include:

- The lining should be evenly and securely attached to the garment.

- The stitches should be even and consistent in size.

- The lining should be free of wrinkles and puckers.

To ensure that my work meets these standards, I use a variety of techniques, including:

- Using the correct needle and thread for the fabric and lining.

- Adjusting the tension of the machine to create even stitches.

- Using a presser foot to help guide the fabric and prevent puckering.

5. What are the safety precautions that you take when using a lockstitch machine?

When using a lockstitch machine, it is important to take the following safety precautions:

- Keep your hands and fingers away from the needle.

- Do not operate the machine if the needle is broken.

- Unplug the machine before making any adjustments.

- Wear appropriate safety gear, such as safety glasses and gloves.

6. What is your experience with troubleshooting lockstitch machines?

I have experience troubleshooting a variety of problems with lockstitch machines, including:

- Thread breakage

- Needle breakage

- Tension problems

- Fabric puckering

When troubleshooting a problem, I first try to identify the source of the problem. Once I have identified the source of the problem, I can take the necessary steps to fix it.

7. How do you stay up-to-date on the latest techniques and developments in lining setting?

I stay up-to-date on the latest techniques and developments in lining setting by reading industry publications, attending trade shows, and taking online courses.

- I read industry publications such as “Sew News” and “Threads” to learn about new products and techniques.

- I attend trade shows such as the “International Textile and Apparel Association” (ITAA) show to see the latest products and meet with other professionals in the industry.

- I take online courses through websites such as “Craftsy” and “Udemy” to learn new techniques and improve my skills.

8. What are your strengths and weaknesses as a lockstitch lining setter?

My strengths as a lockstitch lining setter include my attention to detail, my ability to work independently, and my ability to meet deadlines. I am also proficient in a variety of lining setting techniques and can work with a variety of fabrics.

My weakness is that I am not yet experienced in using all types of lockstitch machines. However, I am eager to learn and I am confident that I can quickly develop the skills necessary to be successful in this role.

9. What are your career goals as a lockstitch lining setter?

My career goals as a lockstitch lining setter are to become a master of my craft and to eventually open my own business. I am passionate about lining setting and I believe that I have the skills and the drive to be successful in this field.

I am also interested in learning more about the different aspects of the garment industry. I am particularly interested in learning more about design and production. I believe that this knowledge will help me to become a more well-rounded professional and to contribute more effectively to the success of my business.

10. What are your salary expectations for this role?

My salary expectations for this role are in line with the industry average for lockstitch lining setters with my experience and skills. I am also willing to negotiate a salary that is commensurate with the responsibilities of the role and the company’s budget.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lockstitch Lining Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lockstitch Lining Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lockstitch Lining Setter is responsible for setting and operating lockstitch machines to sew linings into garments or other products. Key responsibilities include:

1. Machine Setup and Operation

• Set up and adjust lockstitch machines according to specifications

• Load thread onto machines and ensure proper tension

• Position and feed linings into machines for sewing

• Monitor machines during operation and make adjustments as needed

2. Quality Control

• Inspect sewn linings for defects such as uneven stitching, skipped stitches, and puckering

• Trim excess thread and remove any loose ends

• Ensure that linings meet quality standards

3. Maintenance and Repair

• Perform routine maintenance on lockstitch machines

• Identify and troubleshoot machine problems

• Contact appropriate personnel for major repairs

4. Other Duties

• Maintain a clean and organized work area

• Follow safety procedures and wear appropriate personal protective equipment

• May assist with other production tasks as needed

Interview Tips

To prepare for an interview for the Lockstitch Lining Setter position, consider the following tips:

1. Research the Company and Position

• Visit the company website to learn about their values, mission, and products/services

• Review the job description thoroughly to understand the specific requirements of the role

2. Practice Common Interview Questions

• Prepare answers to general interview questions, such as “Tell me about yourself” and “What are your strengths and weaknesses?”

• Consider industry-specific questions, such as “Describe your experience with lockstitch machines” and “How do you ensure quality control in your work?”

3. Highlight Relevant Skills and Experience

• Emphasize your skills in operating lockstitch machines and maintaining a high level of quality in your work

• Quantify your accomplishments whenever possible to demonstrate the impact of your contributions

4. Prepare Questions for the Interviewer

• Asking thoughtful questions shows that you are engaged and interested in the role

• Examples of questions you could ask include: “What are the company’s expectations for this position?” and “What opportunities are there for professional development?”

5. Dress Professionally and Arrive on Time

• First impressions matter, so dress professionally and arrive on time for your interview

• Being punctual shows respect for the interviewer’s time

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lockstitch Lining Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.