Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lockstitch Zipper Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

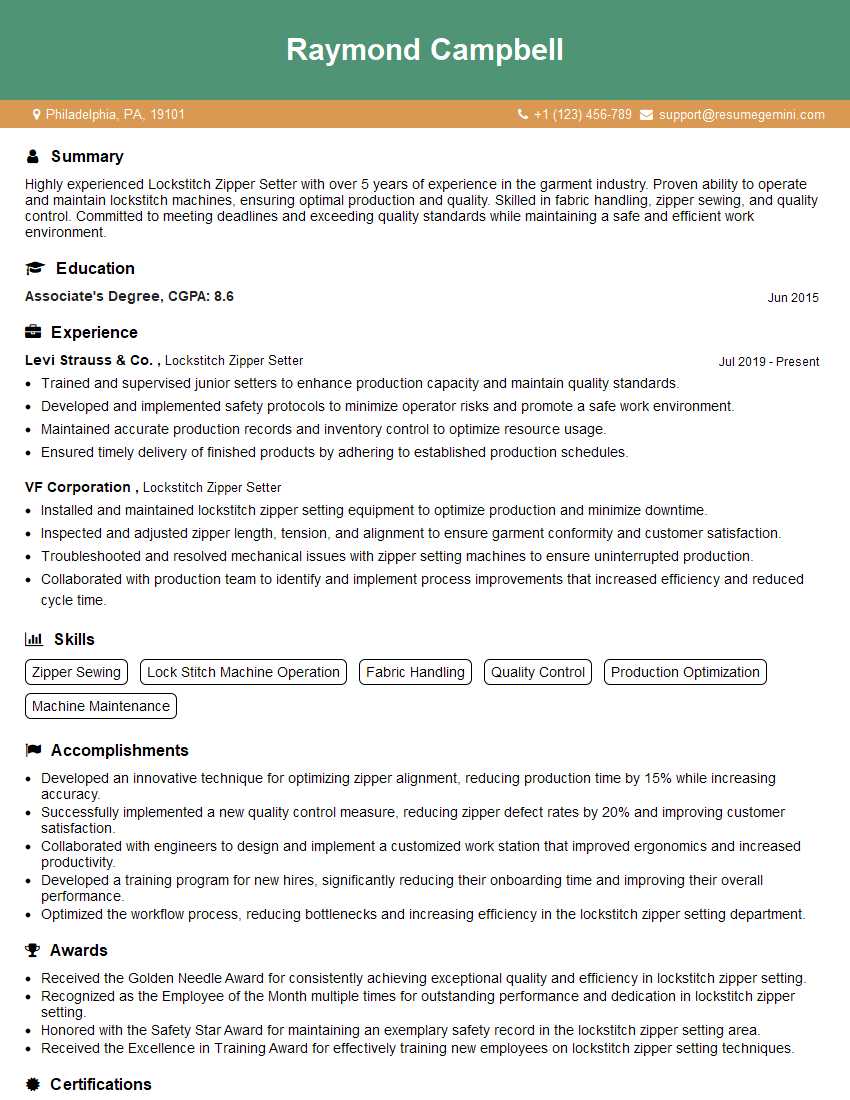

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lockstitch Zipper Setter

1. What are the different types of lockstitch zipper setter machines and what are the key differences between them?

- Chain stitch zipper setting machine: This machine uses a chain stitch to attach the zipper to the fabric. It is commonly used for heavy-duty applications such as jeans, jackets, and bags.

- Lockstitch zipper setting machine: This machine uses a lockstitch to attach the zipper to the fabric. It produces a more durable seam than a chain stitch machine and is often used for lighter-weight fabrics such as dresses, blouses, and skirts.

- Blind stitch zipper setting machine: This machine uses a blind stitch to attach the zipper to the fabric, creating a nearly invisible seam. It is often used for garments where a visible zipper is not desired.

2. What are the key factors to consider when selecting the right lockstitch zipper setter machine for a particular application?

Considerations for selecting a lockstitch zipper setter machine

- Fabric type: The type of fabric being used will determine the type of needle and thread that is needed. For example, a heavy-duty fabric will require a thicker needle and thread than a lightweight fabric.

- Zipper type: The type of zipper being used will also determine the type of machine that is needed. For example, a metal zipper will require a different machine than a plastic zipper.

- Production volume: The production volume will determine the speed and efficiency of the machine that is needed. For example, a high-volume production environment will require a faster machine than a low-volume production environment.

3. What are the different types of needles used in lockstitch zipper setter machines and what are their advantages and disadvantages?

- Regular point needles: These needles are the most common type and are used for a wide range of fabrics. They are available in a variety of sizes and shapes to accommodate different fabrics and zipper types.

- Ball point needles: These needles have a rounded tip that helps to prevent snagging and skipped stitches. They are often used for delicate fabrics or fabrics that are prone to fraying.

- Stretch needles: These needles have a slightly curved tip that helps to prevent the fabric from puckering when sewing stretchy fabrics.

4. What are the different types of thread used in lockstitch zipper setter machines and what are their advantages and disadvantages?

- Polyester thread: This thread is strong and durable, making it a good choice for heavy-duty applications. It is also resistant to fading and shrinking.

- Nylon thread: This thread is strong and elastic, making it a good choice for fabrics that are prone to stretching. It is also resistant to abrasion and mildew.

- Cotton thread: This thread is soft and natural, making it a good choice for delicate fabrics. However, it is not as strong as polyester or nylon thread and is more prone to fading and shrinking.

5. What are the key maintenance tasks that need to be performed on a lockstitch zipper setter machine?

- Clean the machine regularly to remove dust and lint. This will help to prevent the machine from jamming and ensure that it runs smoothly.

- Oil the machine regularly to lubricate the moving parts. This will help to reduce wear and tear and extend the life of the machine.

- Check the needles and thread regularly for damage. Replace them as needed to prevent skipped stitches and other problems.

- Have the machine serviced by a qualified technician on a regular basis to ensure that it is operating properly.

6. What are the different types of defects that can occur when using a lockstitch zipper setter machine and what are the causes of these defects?

- Skipped stitches: Skipped stitches can be caused by a variety of factors, such as a dull needle, incorrect thread tension, or a problem with the machine’s timing.

- Puckering: Puckering can be caused by using a needle that is too large or too small for the fabric, or by sewing too tightly.

- Wrinkles: Wrinkles can be caused by using a fabric that is too thin or too stretchy, or by sewing too quickly.

- Zipper jamming: Zipper jamming can be caused by a variety of factors, such as a bent zipper, a damaged zipper pull, or a problem with the machine’s feed dog.

7. What are the different ways to troubleshoot and resolve problems with a lockstitch zipper setter machine?

- Check the needle: Make sure that the needle is the correct size and type for the fabric being used. Also, check the needle for damage and replace it if necessary.

- Check the thread tension: Make sure that the thread tension is correct. Too much tension can cause skipped stitches, while too little tension can cause the thread to break.

- Check the machine’s timing: Make sure that the machine’s timing is correct. Incorrect timing can cause a variety of problems, such as skipped stitches, puckering, and wrinkles.

- Clean and oil the machine: Make sure that the machine is clean and well-oiled. This will help to prevent the machine from jamming and ensure that it runs smoothly.

- Contact a qualified technician: If you are unable to resolve the problem yourself, contact a qualified technician for assistance.

8. What are the safety precautions that need to be taken when using a lockstitch zipper setter machine?

- Always wear safety glasses when operating the machine.

- Keep your hands away from the needle and other moving parts.

- Do not reach into the machine while it is running.

- Unplug the machine before performing any maintenance or repairs.

- Follow all of the manufacturer’s instructions for safe operation.

9. What are the different types of zipper pulls and how are they attached to the zipper?

- Metal zipper pulls: These pulls are made of metal and are attached to the zipper with a metal rivet.

- Plastic zipper pulls: These pulls are made of plastic and are attached to the zipper with a plastic rivet.

- Cord zipper pulls: These pulls are made of cord and are attached to the zipper with a cord lock.

- Leather zipper pulls: These pulls are made of leather and are attached to the zipper with a metal rivet or a leather lace.

10. What are the different types of zipper stops and how are they attached to the zipper?

- Metal zipper stops: These stops are made of metal and are attached to the zipper with a metal rivet.

- Plastic zipper stops: These stops are made of plastic and are attached to the zipper with a plastic rivet.

- Cord zipper stops: These stops are made of cord and are attached to the zipper with a cord lock.

- Leather zipper stops: These stops are made of leather and are attached to the zipper with a metal rivet or a leather lace.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lockstitch Zipper Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lockstitch Zipper Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lockstitch Zipper Setter is an experienced professional responsible for the operation of industrial machinery used in the manufacturing of zippers. They are expected to meet production targets, ensure quality standards, and maintain a safe work environment.

1. Operate Lockstitch Zipper Setting Machine

The primary duty of a Lockstitch Zipper Setter is to operate a lockstitch zipper setting machine to attach zippers to various types of garments, bags, and other products.

- Adjust machine settings and tension to suit the specific type of zipper, fabric, and intended use

- Load fabric and zippers into the machine and monitor its operation to ensure accurate placement and secure attachment

2. Inspect Zippers and Maintain Quality Standards

Zipper Setters are responsible for inspecting the finished zippers to ensure they meet quality standards. They must identify and correct any defects or issues to maintain product integrity.

- Examine zippers for any visible defects, such as missing teeth, uneven stitching, or fraying

- Perform necessary repairs or adjustments to correct any identified issues and ensure zippers meet specifications

3. Maintain Machine and Work Area

A clean and well-maintained work area and machine are crucial for efficient and safe operation. Zipper Setters are expected to take responsibility for maintaining their workspace.

- Clean and lubricate the zipper setting machine regularly to prevent malfunctions and extend its lifespan

- Maintain a tidy work area, ensuring proper waste disposal and organization of materials

4. Adhere to Safety Protocols

Zipper Setters work with industrial machinery that can pose potential safety hazards. They must adhere to established safety protocols and follow proper operating procedures.

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and earplugs

- Operate machinery only when authorized and follow all safety guidelines to prevent accidents and injuries

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips and tricks to help you ace your Lockstitch Zipper Setter interview:

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and specific requirements for the Lockstitch Zipper Setter position. This knowledge will help you tailor your answers and demonstrate your understanding of the role.

2. Highlight Relevant Skills and Experience

Emphasize your experience and skills that are directly relevant to the job responsibilities. Provide specific examples of your ability to operate lockstitch zipper setting machines, inspect zippers for quality, and maintain a safe work environment.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your experience, skills, and motivation for applying. Practice answering these questions succinctly and confidently.

4. Dress Professionally and Arrive Punctually

First impressions matter, so dress professionally and arrive for the interview on time. Punctuality shows respect for the interviewer’s time and demonstrates your commitment to the opportunity.

5. Ask Thoughtful Questions

Towards the end of the interview, take the opportunity to ask thoughtful questions about the company, the position, or the industry. This shows your engagement and interest in the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lockstitch Zipper Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!