Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Locomotive Pipe Fitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

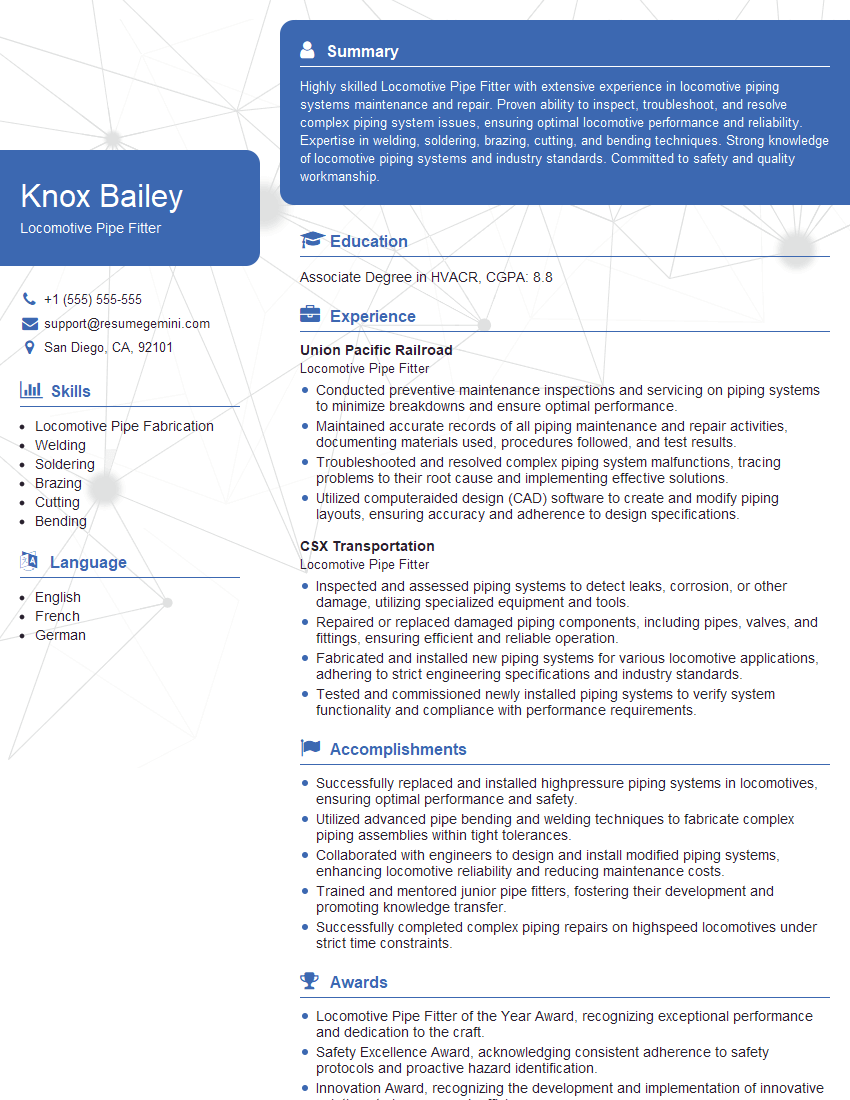

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Locomotive Pipe Fitter

1. How do you ensure the proper alignment of piping during installation?

To ensure proper alignment of piping during installation, I:

- Use measuring tapes, levels, and other tools to establish reference points.

- Calculate the bends and offsets required for each pipe section.

- Utilize alignment tools, such as laser levels or string lines, to guide the installation.

- Check the alignment regularly as the piping is installed.

- Make adjustments as necessary to maintain the desired alignment.

2. What are the primary materials used in locomotive piping systems, and how do you select the appropriate material for different applications?

The primary materials used in locomotive piping systems include:

Carbon Steel:

- Advantages: Strength, durability, low cost.

- Applications: General-purpose air and hydraulic lines.

Stainless Steel:

- Advantages: Corrosion resistance, high strength.

- Applications: Fluid lines with corrosive substances, such as fluids containing acids or solvents.

Copper:

- Advantages: Corrosion resistance, malleability, high thermal conductivity.

- Applications: Fluid lines requiring higher thermal conductivity, such as cooling lines.

Aluminum:

- Advantages: Lightweight, corrosion resistance, high strength-to-weight ratio.

- Applications: Air lines, low-pressure hydraulic lines.

3. Describe the different types of pipe connections used in locomotive piping systems and the situations where each type is preferred.

Types of pipe connections used in locomotive piping systems include:

Threaded Connections:

- Advantages: Ease of assembly, low cost.

- Applications: General-purpose connections for pipes up to 4 inches in diameter.

Flanged Connections:

- Advantages: High joint strength, easy to disassemble for maintenance.

- Applications: High-pressure, high-temperature applications, connections to valves and pumps.

Welded Connections:

- Advantages: Permanent joint, strong and reliable.

- Applications: Critical applications, such as main fluid lines, where leak-proof connections are crucial.

Socket Connections:

- Advantages: Quick and easy to assemble, low cost.

- Applications: Small-diameter plastic or copper pipes, non-critical applications.

4. What are the safety precautions you take when working with piping systems under pressure?

Safety precautions when working with piping systems under pressure include:

- Inspect the system for damage or leaks before pressurizing.

- Wear appropriate personal protective equipment (PPE).

- Install pressure relief devices to protect against over-pressurization.

- Use barricades to keep personnel clear of areas under pressure.

- Bleed off pressure before performing any work on the system.

5. How do you troubleshoot a locomotive piping system that is experiencing leaks or pressure drops?

To troubleshoot a locomotive piping system with leaks or pressure drops:

- Inspect the system for visible leaks using a flashlight or leak detection tool.

- Check for loose or damaged connections.

- Tighten loose connections or replace damaged components as necessary.

- If the leak persists, check the pressure gauge readings.

- Identify any significant pressure drops between different points in the system.

6. Describe the importance of proper documentation in locomotive piping system maintenance and how you maintain accurate records.

Proper documentation is crucial in locomotive piping system maintenance for several reasons:

- It provides a history of repairs, modifications, and inspections.

- It allows for efficient troubleshooting by providing a reference for previous issues.

- It ensures compliance with safety regulations and industry standards.

To maintain accurate records, I use:

- Maintenance logs to record repairs, replacements, and inspections.

- As-built drawings to track modifications to the original piping system.

- Digital documentation systems to store and retrieve records easily.

7. How do you stay updated with the latest advances in locomotive piping technology?

To stay updated with the latest advances in locomotive piping technology:

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Engage with manufacturers and suppliers to learn about new products and technologies.

- Participate in online forums and discussion groups.

8. Explain the methods you use to ensure the quality of your work on locomotive piping systems.

To ensure the quality of my work, I:

- Follow industry standards and best practices.

- Use high-quality materials and components.

- Inspect my work regularly to identify and correct any errors.

- Test the piping system to verify proper functionality.

9. How do you work effectively as part of a team on complex piping projects?

To work effectively as part of a team on complex piping projects:

- Communicate clearly with other team members.

- Cooperate and support each other’s efforts.

- Assist in problem-solving and decision-making.

- Respect and value the contributions of others.

10. Provide an example of a challenging piping project you worked on and how you overcame the challenges.

In a complex locomotive piping project, we encountered several challenges, including:

Space Constraints:

- The locomotive’s engine compartment was densely packed, making it difficult to route the pipes efficiently.

- I used creative pipe bending techniques and utilized available space to overcome this challenge.

Material Compatibility:

- Different types of piping materials had to be connected, ensuring compatibility and preventing leaks.

- I consulted with engineers and used specialized fittings and sealants to ensure proper connections.

Time Constraints:

- The project had a tight deadline, and I had to work efficiently without compromising quality.

- I optimized my workflow, prioritized tasks, and coordinated with other team members to meet the deadline.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Locomotive Pipe Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Locomotive Pipe Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Locomotive Pipe Fitter

A Locomotive Pipe Fitter plays a vital role in maintaining and repairing locomotives, ensuring their smooth and safe operation.

Key responsibilities of a Locomotive Pipe Fitter include:

1. Pipe Fabrication and Installation

- Fabricates and installs new pipes and components, including air lines, fuel lines, and water lines.

- Inspects and tests pipes and fittings to ensure proper operation and compliance with safety standards.

2. Pipe Maintenance and Repair

- Diagnoses and repairs leaks, breaks, and other issues in piping systems.

- Performs preventative maintenance, including cleaning, inspecting, and replacing pipes and fittings.

3. Troubleshooting and Problem-Solving

- Troubleshoots complex piping issues, using knowledge of locomotive systems and fluid dynamics.

- Develops and implements solutions to improve system performance and efficiency.

4. Compliance with Safety Regulations

- Adheres to all safety regulations and procedures related to the handling and installation of pipes.

- Maintains a clean and organized work environment, minimizing potential hazards.

Interview Preparation Tips for a Locomotive Pipe Fitter

To ace an interview for a Locomotive Pipe Fitter position, candidates should prepare thoroughly and demonstrate their skills and experience:

1. Research the Company and Position

- Learn about the company’s history, operations, and culture.

- Understand the specific requirements of the Locomotive Pipe Fitter role and how it aligns with your skills.

2. Highlight Relevant Experience and Skills

- Quantify your accomplishments and provide concrete examples of your work in pipe fabrication, installation, and repair.

- Emphasize your ability to work independently and as part of a team.

3. Practice Common Interview Questions

- Prepare answers to questions about your technical skills, problem-solving abilities, and safety knowledge.

- You can anticipate questions related to locomotive piping systems, troubleshooting, and working in a fast-paced environment.

4. Demonstrate Enthusiasm and Professionalism

- Be enthusiastic and demonstrate your passion for the role.

- Dress professionally, arrive on time, and be respectful of the interviewer.

5. Ask Thoughtful Questions

- Ask questions that show you are engaged and interested in the position.

- Inquire about the company’s commitment to safety, training opportunities, and advancement possibilities.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Locomotive Pipe Fitter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.