Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Log Check Scaler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

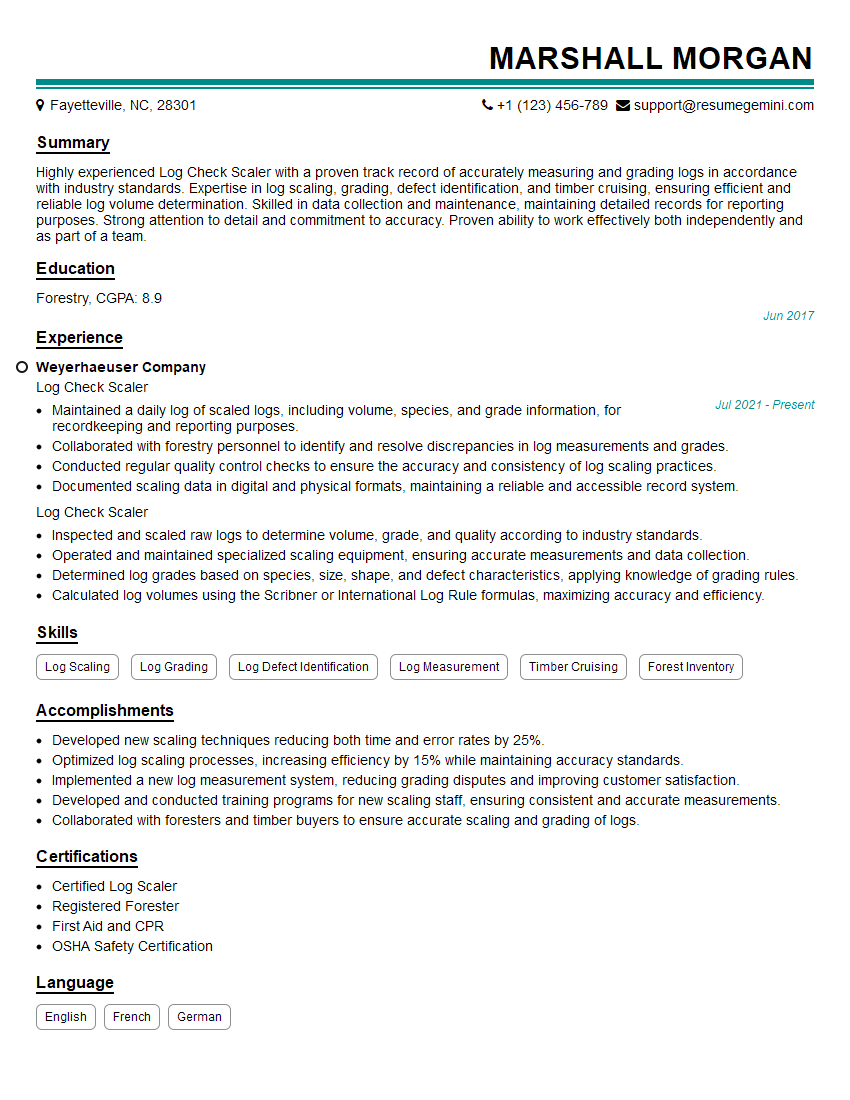

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Log Check Scaler

1. How do you ensure accurate measurements while scaling logs?

To ensure accurate measurements while scaling logs, I follow these steps:

- Regularly calibrate my scaling tools, including calipers, diameter tapes, and grading sticks.

- Inspect logs for defects, such as rot, knots, and splits, which can affect their volume.

- Use the appropriate scaling rules and procedures for the specific species and type of logs being scaled.

- Double-check my measurements for accuracy before recording them.

2. Can you explain the different log grades and their criteria?

Hardwood Grades

- Grade 1: Logs with a minimum diameter of 12 inches, clear of defects, and a length of at least 10 feet.

- Grade 2: Logs with a minimum diameter of 10 inches, clear of major defects but may have some minor defects.

- Grade 3: Logs with a minimum diameter of 8 inches, may have defects but can still be used for lumber and other products.

Softwood Grades

- Grade 1: Logs with a minimum diameter of 12 inches, clear of defects, and a length of at least 16 feet.

- Grade 2: Logs with a minimum diameter of 10 inches, may have some minor defects, and a length of at least 14 feet.

- Grade 3: Logs with a minimum diameter of 8 inches, may have defects but can still be used for construction and other purposes.

3. How do you handle disputes or disagreements with truck drivers or loggers regarding log measurements?

I approach disputes or disagreements with truck drivers or loggers regarding log measurements in a professional and respectful manner. Here’s how I handle such situations:

- Listen to the driver’s or logger’s concerns and try to understand their perspective.

- Review my measurements and the scaling rules used to ensure accuracy.

- Recheck the logs in question or request a second opinion from another scaler if necessary.

- Explain my findings and the basis for my measurements clearly and calmly.

- If an agreement cannot be reached, I may escalate the matter to my supervisor or refer it to an independent third party for resolution.

4. What are the safety procedures you follow while working as a Log Check Scaler?

I prioritize safety in my role as a Log Check Scaler by adhering to the following procedures:

- Wearing appropriate safety gear, including a hard hat, safety glasses, gloves, and sturdy boots.

- Maintaining a safe distance from moving logs and equipment.

- Being aware of my surroundings and potential hazards, such as uneven ground, slippery surfaces, and falling logs.

- Following established traffic patterns and using proper hand signals when directing trucks and equipment.

- Reporting any unsafe conditions or accidents promptly to my supervisor.

5. How do you stay updated on the latest scaling rules and industry regulations?

To stay updated on the latest scaling rules and industry regulations, I take the following steps:

- Attend industry conferences and workshops.

- Read trade publications and journals.

- Subscribe to newsletters from scaling organizations.

- Consult with experienced scalers and industry professionals.

- Participate in continuing education programs to enhance my knowledge and skills.

6. What are the different types of log defects and how do they affect log value?

Common log defects include:

- Knots: Reduce log strength and can make it difficult to process.

- Splits: Cracks in the wood that can weaken it and reduce its value.

- Rot: Decay or deterioration of the wood that can affect its structural integrity.

- Crooks: Bends or curves in the log that can make it difficult to saw and process.

- Sweep: A gradual curve along the length of the log that can affect its usability.

These defects can significantly impact log value, as they reduce the amount of usable wood and increase processing costs.

7. What is the importance of accurate log scaling in the forest industry?

Accurate log scaling is crucial in the forest industry for several reasons:

- Fair payment: Ensures that loggers and landowners are fairly compensated for their products.

- Proper resource management: Helps prevent overharvesting and promotes sustainable forest practices.

- Accurate inventory: Provides accurate data on timber resources, which is essential for planning and decision-making.

- Efficient processing: Facilitates efficient log processing by providing accurate information on log size and quality.

- Quality control: Helps ensure the quality of lumber and other wood products.

8. What factors can affect the quality of logs for lumber production?

Several factors can affect the quality of logs for lumber production, including:

- Species of tree: Different tree species have different wood properties that affect their suitability for lumber.

- Log size and shape: Larger logs with regular shapes are generally more desirable for lumber production.

- Wood defects: Knots, splits, rot, and other defects can reduce the quality and value of logs.

- Growth conditions: Logs from trees that have grown in favorable conditions tend to be higher quality.

- Harvesting and handling practices: Proper felling, bucking, and transportation can help preserve log quality.

9. What are the advantages of using technology in log scaling?

Technology can provide several advantages in log scaling, including:

- Improved accuracy: Electronic scaling devices can measure logs more accurately than manual methods.

- Increased efficiency: Technology streamlines the scaling process, reducing time and labor costs.

- Real-time data: Electronic systems provide immediate data on log measurements, allowing for timely decision-making.

- Reduced human error: Automation minimizes the risk of errors associated with manual measurements.

- Enhanced traceability: Technology allows for better tracking and documentation of log scaling data.

10. How do you maintain your scaling tools and ensure their accuracy?

To maintain the accuracy of my scaling tools, I adhere to the following practices:

- Regular calibration: Calibrating tools regularly using certified reference materials ensures they meet industry standards.

- Proper storage: Storing tools in a clean, dry environment prevents damage and maintains their accuracy.

- Visual inspection: Inspecting tools before each use checks for any visible signs of damage or wear.

- Regular cleaning: Cleaning tools removes dirt and debris that can affect their performance.

- Maintenance and repair: Promptly addressing any maintenance or repair needs ensures tools are in optimal working condition.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Log Check Scaler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Log Check Scaler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Log Check Scalers are responsible for the accurate measurement and grading of logs at timber mills or logging operations.

1. Measure and Grade Logs

They measure the diameter, length, and taper of logs using a variety of tools, including calipers, rules, and tapes.

- Classify logs according to species, quality, and size.

- Determine the volume and value of each log based on its measurements and grade.

2. Inspect Logs

Inspect logs for defects, such as knots, splits, and decay, which can affect their value.

- Identify and mark logs that are not suitable for processing.

- Maintain records of all logs inspected, including their measurements, grade, and defects.

3. Operate Machinery

Operate machinery, such as log sorters and conveyors, to move logs through the processing line.

- Ensure that machinery is operating correctly and efficiently.

- Troubleshoot and resolve any mechanical issues.

4. Maintain Safety Standards

Maintain a safe work environment by following established safety procedures.

- Wear appropriate safety gear, including hard hats, safety glasses, and gloves.

- Follow all instructions and guidelines provided by supervisors.

Interview Tips

To ace an interview for a Log Check Scaler position, it is important to prepare thoroughly and showcase your skills and experience.

1. Research the Company and Position

Before the interview, research the company and the specific Log Check Scaler position you are applying for.

- Visit the company’s website to learn about their history, products, and culture.

- Review the job description carefully to identify the key responsibilities and qualifications.

2. Practice Answering Common Interview Questions

Practice answering common interview questions that may be asked in an interview for a Log Check Scaler position.

- Tell me about your experience in measuring and grading logs.

- How do you handle logs with defects?

- What is your safety record?

3. Highlight your Transferable Skills

If you have not worked as a Log Check Scaler before, highlight transferable skills that are relevant to the position.

- Experience in a similar role, such as a lumber inspector or quality control inspector.

- Strong attention to detail and accuracy.

- Ability to work independently and as part of a team.

4. Be prepared to talk about the Industry

In the interview, you may be asked questions about the logging industry and trends.

- Demonstrate your knowledge of the industry by reading trade publications and attending industry events.

- Be prepared to discuss your thoughts on the future of the industry.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Log Check Scaler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Log Check Scaler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.