Feeling lost in a sea of interview questions? Landed that dream interview for Log Peeler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Log Peeler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

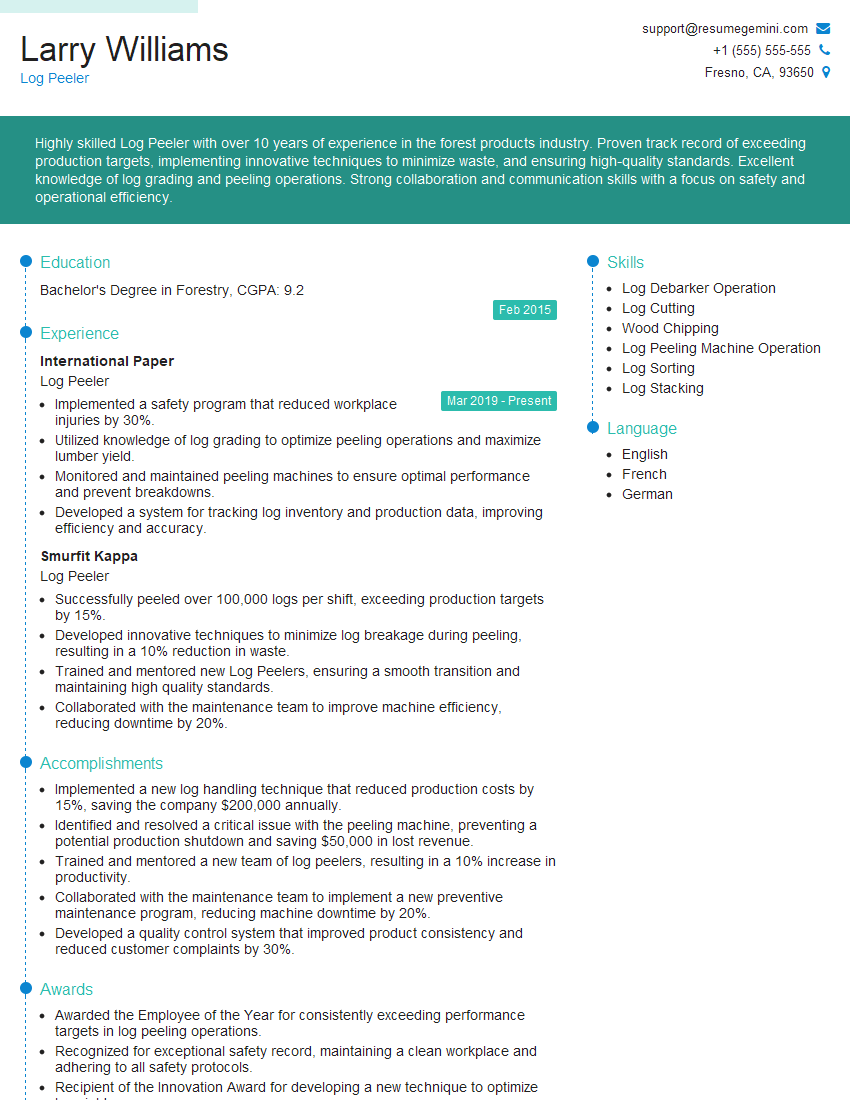

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Log Peeler

1. How do you ensure that the logs are peeled to the required thickness?

To ensure the logs are peeled to the required thickness, I use a combination of techniques:

- Caliper measurements: I use a caliper to measure the thickness of the logs at various points along their length. This helps me identify any areas that need additional peeling.

- Visual inspection: I also visually inspect the logs as they are being peeled. This allows me to identify any defects or inconsistencies in the peeling process.

- Experience and judgment: With experience, I have developed a good understanding of how different types of logs peel. This allows me to adjust the peeling process accordingly to achieve the desired thickness.

2. What types of logs can you peel?

I have experience peeling a wide variety of logs, including:

- Softwoods: pine, spruce, fir

- Hardwoods: oak, maple, birch

- Exotic woods: mahogany, teak, rosewood

I am also familiar with the different peeling characteristics of each type of wood. This allows me to adjust the peeling process accordingly to achieve the best results.

3. What is the difference between rotary peeling and veneer peeling?

Rotary peeling is a process in which a log is rotated against a stationary knife. This produces a continuous sheet of veneer. Veneer peeling, on the other hand, is a process in which a log is peeled in a helical pattern. This produces a thicker sheet of veneer that is more stable and less prone to cracking.

I am proficient in both rotary peeling and veneer peeling. I can choose the appropriate peeling method based on the type of log and the desired end product.

4. How do you maintain the log peeler?

Regular maintenance is essential to keep the log peeler operating at peak efficiency. I perform the following maintenance tasks on a regular basis:

- Inspecting the knives: I inspect the knives for wear and tear. I sharpen or replace the knives as needed.

- Lubricating the bearings: I lubricate the bearings to reduce friction and wear.

- Adjusting the settings: I adjust the settings of the log peeler to ensure that it is peeling the logs to the correct thickness and quality.

I also follow the manufacturer’s recommended maintenance schedule.

5. What are the safety precautions that you take when operating a log peeler?

Safety is my top priority when operating a log peeler. I take the following precautions:

- Wearing appropriate safety gear: I wear safety glasses, gloves, and earplugs when operating the log peeler.

- Keeping the work area clean: I keep the work area clean and free of debris.

- Being aware of my surroundings: I am aware of my surroundings and the location of other workers.

- Following the manufacturer’s instructions: I follow the manufacturer’s instructions for operating the log peeler.

I am committed to working safely and efficiently.

6. What is your experience with troubleshooting log peeler problems?

I have experience troubleshooting a variety of log peeler problems, including:

- Knife problems: dull knives, chipped knives, broken knives

- Bearing problems: worn bearings, noisy bearings, seized bearings

- Hydraulic problems: leaks, low pressure, no pressure

- Electrical problems: blown fuses, tripped breakers, faulty wiring

I use a combination of troubleshooting techniques to identify and resolve log peeler problems. I am also familiar with the manufacturer’s recommended troubleshooting procedures.

7. What is your quality control process for peeled logs?

My quality control process for peeled logs includes the following steps:

- Visual inspection: I visually inspect the peeled logs for defects such as cracks, knots, and splits.

- Caliper measurements: I use a caliper to measure the thickness of the peeled logs.

- Moisture content testing: I test the moisture content of the peeled logs to ensure that they are within the desired range.

I also maintain a log of all quality control inspections. This helps me to track the quality of the peeled logs and identify any trends.

8. How do you handle waste from the log peeling process?

I handle waste from the log peeling process in an environmentally responsible manner. I recycle the wood chips and sawdust. I also dispose of the bark and other waste materials in accordance with local regulations.

9. What is your experience with working in a team environment?

I have experience working in a team environment in a variety of settings. I am able to work independently and as part of a team. I am also able to communicate effectively with my team members.

10. What is your availability?

I am available to work flexible hours, including weekends and holidays.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Log Peeler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Log Peeler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Log Peelers play a pivotal role in the lumber industry by preparing logs for processing. They operate specialized machinery to remove bark and other surface defects from logs, ensuring optimal quality for further processing.

1. Log Preparation

Inspect logs for defects such as knots, splits, and rot.

- Measure logs to determine the appropriate peeling length.

- Position logs securely on the peeling machine.

2. Bark Removal

Operate log peeling machines to remove bark from logs.

- Calibrate and adjust peeling blades for efficient bark removal.

- Monitor the peeling process to ensure optimal bark removal without damaging the wood.

3. Defect Removal

Identify and mark wood defects such as knots, splits, and stains.

- Use specialized tools to remove or trim away defects from logs.

- Ensure that logs meet the required quality standards for further processing.

4. Log Stacking

Stack logs according to size, grade, and specifications.

- Organize logs in designated storage areas to facilitate handling and transportation.

- Maintain accurate records of log inventory and location.

Interview Tips

Preparing effectively for a Log Peeler interview involves understanding the key job responsibilities and showcasing relevant skills and experience. Here are some valuable tips to help you ace the interview:

1. Research the Industry and Company

Familiarize yourself with the lumber industry, its processes, and the company you’re applying to. Research their products, market reputation, and environmental practices.

- Read industry publications and attend trade shows.

- Visit the company’s website and social media pages for company information.

2. Highlight Relevant Skills and Experience

Emphasize your skills in log preparation, bark removal, defect identification, and log stacking. Quantify your accomplishments and provide specific examples to demonstrate your efficiency and attention to detail.

- Mention any previous experience operating log peeling machinery.

- Quantify your productivity in terms of logs processed per hour or shift.

3. Demonstrate Safety Awareness

Log Peeling involves working with heavy machinery and hazardous materials. Highlight your commitment to safety by discussing your understanding of safety protocols, proper handling of machinery, and personal protective equipment.

- Mention any safety certifications or training you have received.

- Describe your experience in following safety procedures and reporting hazards.

4. Prepare Questions for the Interviewer

Asking thoughtful questions shows interest and engagement in the role. Prepare questions about the company’s production goals, environmental initiatives, and career advancement opportunities.

- Ask about the company’s commitment to sustainability and reducing waste.

- Inquire about opportunities for professional development and training.

Next Step:

Now that you’re armed with the knowledge of Log Peeler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Log Peeler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini