Are you gearing up for a career in Log Stacker Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Log Stacker Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

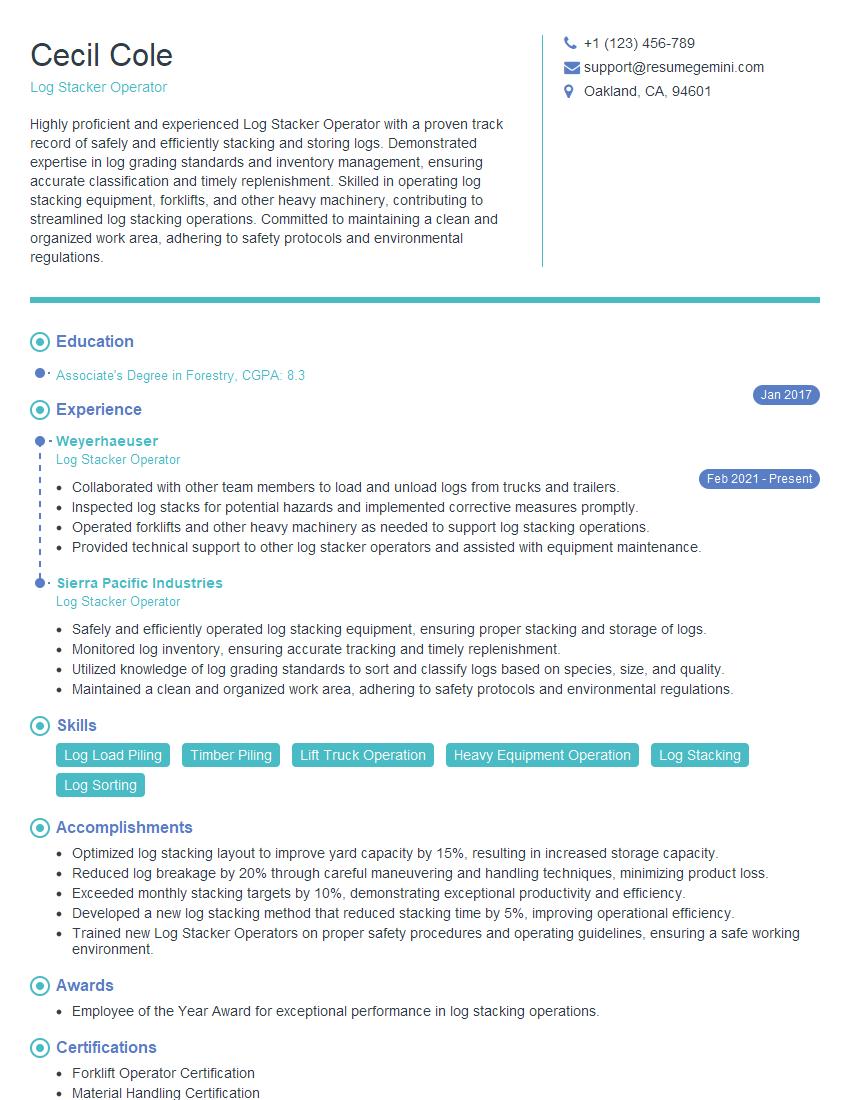

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Log Stacker Operator

1. What are the key responsibilities of a Log Stacker Operator?

The primary responsibilities of a Log Stacker Operator include:

- Operating log stackers to load, stack, and unload logs

- Ensuring that logs are stacked properly and securely

- Maintaining and inspecting log stackers to ensure they are in good working order

- Following all safety protocols and procedures

2. What are the different types of log stackers?

There are two main types of log stackers:

Hydraulic Log Stackers

- Powered by hydraulic systems

- Use hydraulic cylinders to extend and retract the boom and grapple

- Commonly used in large-scale logging operations

Cable Log Stackers

- Powered by cables and pulleys

- Use cables to extend and retract the boom and grapple

- More compact and maneuverable than hydraulic log stackers

- Suitable for smaller-scale logging operations

3. What are the safety hazards associated with operating a log stacker?

Operating a log stacker involves several safety hazards, including:

- Falling logs

- Moving machinery

- Electrical hazards

- Slips and falls

- Noise and vibration

4. How do you ensure the safety of yourself and others when operating a log stacker?

To ensure safety when operating a log stacker, I always:

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, and gloves

- Inspect the log stacker before each use to ensure it is in good working order

- Follow all safety protocols and procedures

- Be aware of my surroundings and potential hazards

- Maintain a safe distance from other workers and equipment

5. What are the daily maintenance tasks required for a log stacker?

The daily maintenance tasks for a log stacker include:

- Checking the fluid levels, including hydraulic oil, engine oil, and coolant

- Inspecting the tires for wear and tear

- Greasing moving parts

- Tightening bolts and nuts

- Cleaning the machine

6. How do you troubleshoot common problems with a log stacker?

Some common problems with log stackers and their troubleshooting steps include:

- Log stacker won’t start: Check the battery, starter, and fuel supply

- Log stacker won’t lift logs: Check the hydraulic system for leaks or blockages

- Log stacker is leaking fluid: Identify the source of the leak and replace the faulty component

- Log stacker is making strange noises: Inspect the moving parts for wear and tear

7. What are the different types of logs that can be handled by a log stacker?

Log stackers can handle a variety of logs, including:

- Softwood logs (e.g., pine, fir, spruce)

- Hardwood logs (e.g., oak, maple, birch)

- Pulpwood logs (e.g., aspen, poplar)

- Sawlogs (e.g., logs intended for lumber production)

8. How do you determine the weight and volume of logs?

To determine the weight and volume of logs, I use a variety of methods, including:

- Log scaling: Using a log scale stick to measure the diameter and length of logs

- Weight scaling: Weighing logs using a crane scale or load cells

- Volume calculation: Using mathematical formulas to calculate the volume of logs based on their dimensions

9. What are the environmental regulations that apply to log stacking operations?

The environmental regulations that apply to log stacking operations include:

- Air quality regulations: Controlling emissions from log stackers

- Water quality regulations: Preventing runoff from log stacking areas from polluting water sources

- Noise pollution regulations: Limiting noise levels from log stacking operations

- Waste management regulations: Proper disposal of waste materials generated during log stacking

10. How do you work effectively as part of a team in a log stacking operation?

To work effectively as part of a team in a log stacking operation, I:

- Communicate effectively with my team members

- Cooperate and support each other

- Share knowledge and skills

- Follow instructions and take initiative

- Maintain a positive and collaborative work environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Log Stacker Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Log Stacker Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Log Stacker Operators are responsible for operating log stacking equipment to load, unload, and stack logs. They play a crucial role in the efficient functioning of logging operations and the safety of the workplace. Their primary responsibilities include:

1. Equipment Operation

Log Stacker Operators are highly skilled in operating log stackers, including forklifts, skidders, and front-end loaders. They are responsible for:

- Loading and unloading logs from trucks, trailers, and rail cars

- Stacking logs in designated areas to ensure proper storage

- Moving logs within the yard or mill area as required

2. Log Handling

Log Stacker Operators must have a keen eye for proper log handling techniques. They are responsible for:

- Inspecting logs for defects or damage

- Separating and sorting logs based on size, species, and quality

- Maintaining a safe and organized work area

3. Equipment Maintenance

Log Stacker Operators are responsible for the basic maintenance and repair of their equipment. They are expected to:

- Perform regular inspections and identify any potential problems

- Lubricate, adjust, and clean equipment as needed

- Report any major mechanical issues to supervisors immediately

4. Safety and Compliance

Safety is paramount for Log Stacker Operators. They are responsible for:

- Following all safety regulations and protocols

- Wearing appropriate personal protective equipment

- Maintaining a clean and organized work area

- Reporting any unsafe conditions or practices

Interview Tips

To ace the interview for a Log Stacker Operator position, candidates should prepare thoroughly and demonstrate their skills and experience. Here are some tips:

1. Research the Company and Position

Research the logging company and the specific position you are applying for. Learn about their operations, equipment, and safety protocols. This will help you understand the company’s needs and how your skills align with them.

2. Highlight Your Experience and Skills

In the interview, emphasize your experience in operating log stacking equipment and handling logs. Quantify your accomplishments whenever possible, such as the number of logs you have stacked or the amount of time you have operated equipment without incident.

3. Showcase Your Safety Awareness

Log Stacking Operators must prioritize safety. Discuss your understanding of safety regulations, your experience in following protocols, and any safety improvements you have implemented in previous roles.

4. Demonstrate Your Problem-Solving Abilities

Interviewers will want to know how you handle challenges and solve problems. Prepare examples of situations where you used critical thinking and problem-solving skills to resolve issues related to equipment operation or log handling.

5. Practice Common Interview Questions

Research common interview questions for Log Stacker Operators and practice your answers. This will help you feel more confident and prepared during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Log Stacker Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!