Feeling lost in a sea of interview questions? Landed that dream interview for Logging Rafter Laborer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Logging Rafter Laborer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

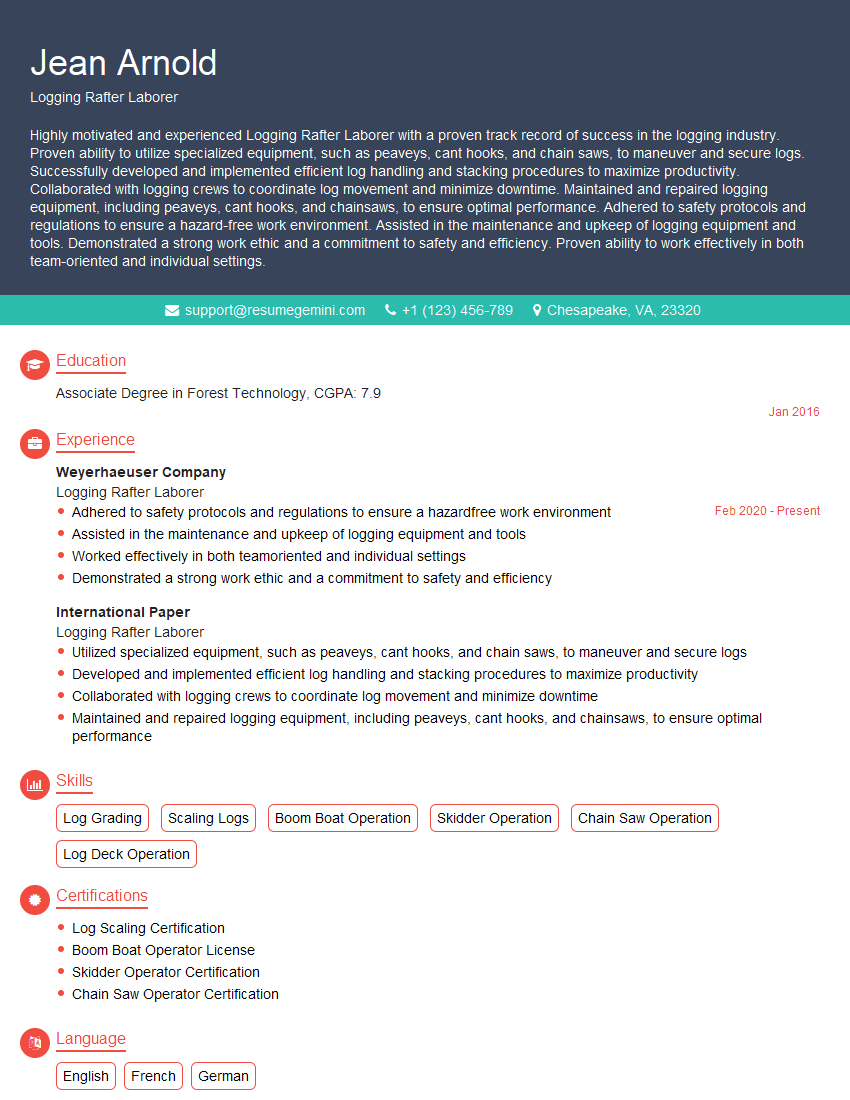

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Logging Rafter Laborer

1. Describe the process of rafting logs?

Rafting logs involves assembling individual logs into bundles called rafts for transportation or storage. The process typically includes the following steps:

- Log Sorting: Logs are sorted by species, size, and quality.

- Log Preparation: Logs are trimmed, debarked, and bundled together using steel cables or straps.

- Assembling the Raft: Bundles are interconnected to form a stable and buoyant raft.

- Securing the Raft: The raft is secured with additional cables, chains, or anchors to prevent it from breaking apart.

2. How do you ensure the safety of others when working on a logging rafter?

Maintaining a Clean and Organized Work Area:

- Keep decks clear of tripping hazards.

- Store tools and equipment properly.

Proper Lifting Techniques:

- Use proper lifting posture to avoid injuries.

- Get assistance for heavy loads.

Working with Machinery:

- Follow safety protocols when operating machinery.

- Wear appropriate protective gear.

Communication:

- Communicate clearly with colleagues to avoid misunderstandings.

- Report any hazards or unsafe conditions promptly.

3. How do you determine the weight and volume of a log?

There are several methods to determine the weight and volume of a log:

- Scaling: Using a scaling stick or caliper to measure log dimensions and then referring to volume tables.

- Weighing: Submerging the log in water and measuring the weight of the displaced water.

- Log Volume Equations: Applying mathematical formulas that consider log dimensions and species.

- Log Scanners: Using specialized equipment to scan and calculate log volume and weight.

4. What are the common defects found in logs and how do they affect their value?

Common defects in logs include:

- Knots: Branches embedded in the wood, reducing strength and value.

- Checks: Cracks in the wood, weakening the structure.

- Rot: Decay caused by fungi or bacteria, reducing the log’s usability.

- Sweep: A curvature in the log, affecting its straightness and quality.

- Warp: A distortion in the shape of the log, impacting its dimensional stability.

5. How do you maintain and repair logging equipment?

To maintain and repair logging equipment effectively:

- Regular Inspections: Conduct regular checks for wear and tear, loose parts, or leaks.

- Lubrication: Grease and oil all moving parts according to manufacturer’s recommendations.

- Cleaning: Keep equipment clean to prevent dirt and debris buildup.

- Minor Repairs: Perform basic repairs, such as replacing belts or hoses, on-site.

- Major Repairs: For complex repairs, consult with authorized mechanics or manufacturers.

6. Describe the different types of logging rafting systems?

There are several types of logging rafting systems:

- Booms: Floating structures used to contain and guide logs during rafting.

- Rafts: Bundles of logs interconnected to form a floating platform.

- Towboats: Boats used to tow rafts or booms through waterways.

- Cableways: Overhead cable systems used to transport logs across difficult terrain.

- Conveyors: Belt or chain systems used to move logs on land.

7. How do you handle different log species and grades?

Handling different log species and grades requires:

- Identification: Distinguishing between species and grades based on physical characteristics.

- Sorting: Separating logs into different species and grades to ensure proper processing and value.

- Storage: Storing logs under appropriate conditions to prevent damage or deterioration.

- Transportation: Using suitable methods for transporting different species and grades to maintain quality.

8. What are the environmental considerations when working on a logging rafter?

Environmental considerations when working on a logging rafter include:

- Waterway Protection: Preventing pollution or damage to waterways during log transportation.

- Wildlife Disturbance: Minimizing disruption to wildlife habitats and migration patterns.

- Erosion Control: Implementing measures to prevent soil erosion from logging activities.

- Waste Management: Disposing of waste materials, such as bark and debris, responsibly.

- Compliance: Adhering to environmental regulations and guidelines.

9. What are the key safety hazards in logging rafting and how do you mitigate them?

Key safety hazards in logging rafting include:

- Falls Overboard: Wearing life jackets and using safety harnesses to prevent drowning.

- Log Rolling: Securing logs properly to prevent them from rolling or shifting.

- Machinery Hazards: Following safety protocols and using proper guarding for machinery.

- Weather Conditions: Monitoring weather forecasts and taking precautions in inclement weather.

- First Aid and Emergency Preparedness: Having first aid kits and emergency communication devices available.

10. How do you stay updated with industry best practices and regulations related to logging rafting?

To stay updated with industry best practices and regulations related to logging rafting:

- Attend Industry Events: Participate in conferences, workshops, and trade shows.

- Read Industry Publications: Subscribe to industry magazines and journals.

- Network with Professionals: Connect with other logging professionals and share knowledge.

- Receive Training: Attend training programs and workshops offered by industry organizations.

- Monitor Regulatory Agencies: Stay informed about updates and changes in regulations from relevant agencies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Logging Rafter Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Logging Rafter Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Logging Rafter Laborers are employed in logging companies to help with various operations. They typically perform manual labor and assist with the movement and assembly of logs.

1. Log Handling and Sorting

Assist in the handling and sorting of logs at various stages of the logging process.

- Unloading logs from trucks or other transportation methods

- Sorting logs by size, species, or other criteria

2. Equipment Operation and Maintenance

Operate and maintain various equipment used in logging operations.

- Forklifts or skidders to move logs

- Chainsaws to cut logs

- Debarkers to remove bark from logs

3. Rafter Assembly and Repair

Participate in the assembly and repair of logging rafters, which are used to transport logs.

- Inspect rafters for damage and make necessary repairs

- Assemble rafters according to specifications

4. Safety and Compliance

Follow all safety regulations and procedures.

- Wear appropriate protective gear, such as hard hats, safety glasses, and gloves

- Operate equipment safely and efficiently

Interview Tips

Interviewing for a job as a Logging Rafter Laborer can involve questions about your experience, skills, and safety knowledge. Here are some tips to help you prepare for and ace your interview:

1. Research the company and position

Before the interview, take some time to research the logging company and the specific position you are applying for. Familiarize yourself with their operations, values, and any specific requirements for the role.

- Visit the company’s website to learn about their history, services, and culture.

- Read online reviews and articles to gain insights into the company’s reputation and work environment.

- Check industry publications or job boards for specific information about the position and the company’s expectations.

2. Highlight relevant experience and skills

In your interview, emphasize your relevant experience and skills that align with the job requirements. Quantify your accomplishments whenever possible.

- Describe your experience in handling and sorting logs, operating logging equipment, and assembling rafters.

- Provide examples of how you have contributed to safety and efficiency in previous roles.

- Mention any certifications or training you have completed that are relevant to the position.

3. Demonstrate safety knowledge and commitment

Logging is a physically demanding and potentially hazardous industry. Interviewers will be keen to assess your understanding of safety protocols and your commitment to working safely.

- Explain your understanding of common safety hazards in logging operations.

- Describe your experience in following safety procedures and using protective equipment.

- Emphasize your commitment to maintaining a safe work environment for yourself and others.

4. Prepare for common interview questions

In addition to questions about your experience and skills, you can expect to be asked common interview questions. Prepare your answers to questions such as:

- Tell me about yourself and your experience.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- How do you handle working in a physically demanding environment?

- What are your salary expectations?

5. Dress appropriately and arrive on time

First impressions matter. Dress professionally for your interview and arrive on time. This shows that you respect the interviewer’s time and that you are serious about the opportunity.

- Wear clean, pressed clothing that is appropriate for a work environment.

- Consider wearing safety boots or work boots if you have them.

- Plan your route in advance and allow extra time for traffic or unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Logging Rafter Laborer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.