Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Longshore Equipment Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Longshore Equipment Operator so you can tailor your answers to impress potential employers.

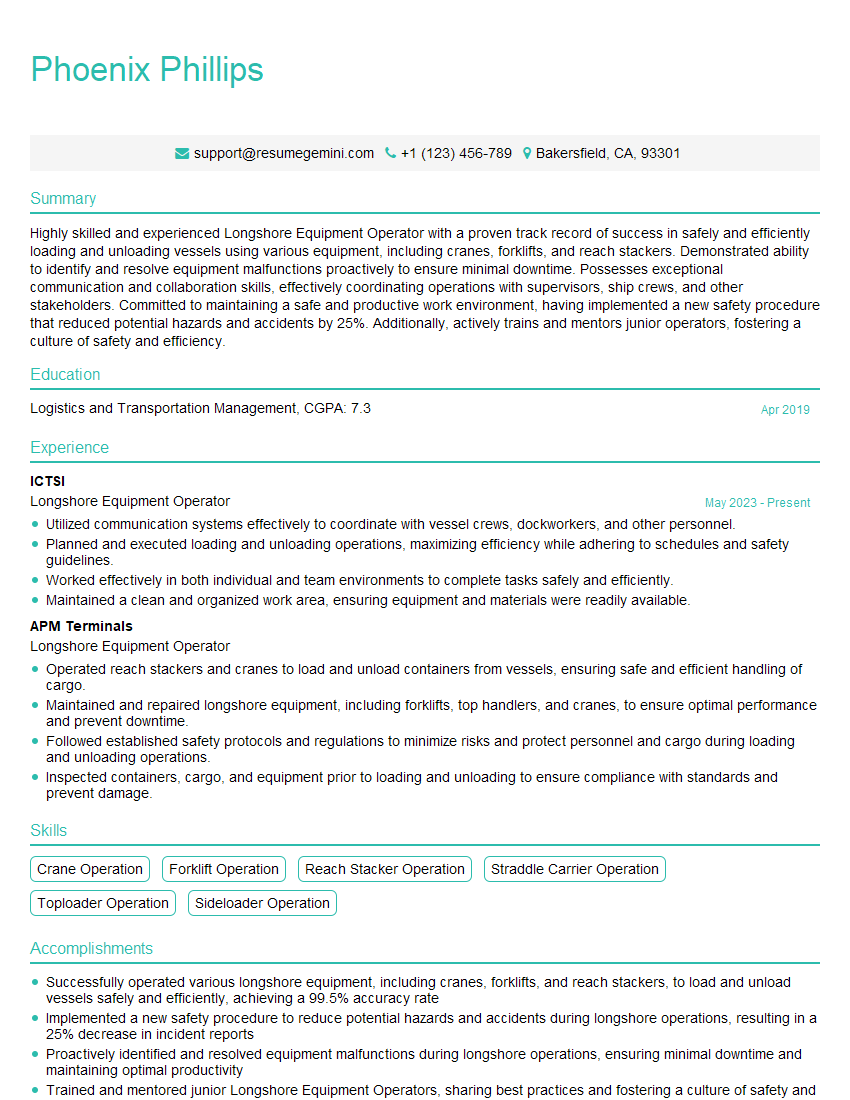

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Longshore Equipment Operator

1. What are the different types of longshore equipment and what are their primary functions?

There are various types of longshore equipment used for different purposes in the loading and unloading of cargo from ships. Some common types include:

- Cranes: Used for lifting and moving heavy cargo between ships and the dock.

- Forklifts: Used for transporting goods on pallets or in containers within the terminal.

- Reach stackers: Similar to forklifts but with a longer reach, used for stacking containers in high racks.

- Straddle carriers: Used specifically for handling containers, straddling over the top of them for transportation.

- Mobile harbor cranes: Self-propelled cranes used for heavy lifting operations on the dock.

2. Describe the safety procedures that must be followed when operating longshore equipment.

- Pre-operation checks: Inspect equipment thoroughly before use, checking for any damage or leaks.

- Load securement: Ensure that all cargo is properly secured and balanced before lifting.

- Load capacity limits: Never exceed the weight capacity of the equipment.

- Clear communication: Maintain clear communication with other crew members and use hand signals when necessary.

- Visibility and obstacles: Be aware of your surroundings and avoid obstacles while operating equipment.

- Personal protective equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and high-visibility clothing.

3. How do you troubleshoot common problems that arise when operating longshore equipment?

Troubleshooting problems with longshore equipment requires a combination of knowledge and experience. Some common problems and solutions include:

- Hydraulic leaks: Inspect for leaks in hoses or cylinders, tighten fittings, or replace damaged components.

- Engine problems: Check fuel levels, air filters, and spark plugs. Consult the manufacturer’s manual for specific troubleshooting steps.

- Electrical issues: Inspect wiring for damage, check fuses and breakers, or contact an electrician for assistance.

- Load instability: Adjust the load position or use additional straps to secure it. Avoid sudden movements or overloading.

- Operator errors: Review operating procedures and ensure proper technique is being used. Seek guidance from experienced operators if necessary.

4. What are the key factors to consider when planning a cargo handling operation using longshore equipment?

- Cargo type and volume: Determine the weight, dimensions, and handling requirements of the cargo.

- Vessel specifications: Consider the size, draft, and cargo capacity of the ship.

- Terminal layout: Assess the availability of equipment, storage areas, and transportation routes.

- Weather conditions: Factor in weather conditions that may affect equipment operation or cargo safety.

- Time constraints: Estimate the expected time for loading or unloading operations and plan accordingly.

5. How do you maintain and service longshore equipment to ensure its optimal performance?

- Regular inspections: Conduct daily or weekly inspections to identify and address potential issues.

- Lubrication: Adhere to manufacturer’s recommendations for lubrication intervals and use appropriate lubricants.

- Filter changes: Replace air filters, oil filters, and hydraulic filters regularly to maintain fluid cleanliness.

- Fluid level checks: Monitor fluid levels and top up or replace as necessary, ensuring proper operation of hydraulics and engines.

- Major repairs: Seek professional assistance for major repairs or overhauls, following manufacturer’s guidelines.

6. What are the environmental and safety regulations that apply to longshore equipment operations?

- Emission standards: Comply with local and national regulations regarding engine emissions and noise levels.

- Spill prevention: Implement measures to prevent and contain fuel or hydraulic fluid spills.

- Waste management: Adhere to proper disposal procedures for used oils, filters, and other waste materials.

- Operator training: Ensure that operators are trained and certified in accordance with applicable regulations.

- Safety protocols: Follow established safety protocols for equipment operation, including proper use of PPE and adherence to load limits.

7. Describe a situation where you successfully resolved a challenging issue during a longshore equipment operation.

In one instance, I encountered a hydraulic leak during a crane operation. I promptly identified the source of the leak and used available resources to temporarily seal the leak, allowing us to complete the cargo handling operation without further delays. I then arranged for professional repair of the leak to ensure continued safe and efficient operation.

8. How do you handle working in a team environment when operating longshore equipment?

- Effective communication: Maintain clear and open communication with team members to coordinate operations and avoid misunderstandings.

- Collaboration: Engage with other operators to assist with challenges, such as managing heavy or bulky cargo.

- Shared responsibility: Recognize the importance of shared responsibility for safety and efficiency.

- Flexibility and adaptability: Be prepared to adjust roles or duties as needed to support the team’s goals.

- Conflict resolution: Address conflicts or disagreements in a professional and respectful manner, seeking solutions that benefit the team.

9. What are your career goals related to longshore equipment operation?

My career goal is to continue developing my expertise as a Longshore Equipment Operator and contribute to the smooth and efficient operation of the terminal. I am keen on expanding my knowledge of other equipment types and gaining experience in specialized operations, such as handling hazardous materials.

10. Do you have any questions for me regarding this position or our company?

- What are the company’s safety procedures and policies?

- What opportunities are there for professional development and advancement within the company?

- How does the company ensure compliance with environmental regulations?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Longshore Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Longshore Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Longshore Equipment Operators hold the responsibility of executing a range of tasks within the maritime industry. These individuals are entrusted with the operation of specialized equipment, such as cranes and forklifts, to facilitate the loading and offloading of cargo onto vessels.

1. Crane Operation

One of their core duties involves operating cranes, employing their precision and dexterity to maneuver heavy containers with utmost safety and efficiency.

- Position cranes to align with designated loading or unloading areas

- Control crane movements and maintain stability

2. Forklift Operation

In addition, they are skilled in operating forklifts for the transportation of cargo within port facilities.

- Maneuver forklifts through narrow spaces and around obstacles

- Load and unload cargo onto and off of trailers

3. Equipment Maintenance

Beyond operating equipment, Longshore Equipment Operators are also responsible for its upkeep and maintenance.

- Conduct routine inspections to identify potential issues

- Perform basic repairs and adjustments to ensure equipment is in optimal condition

4. Safety Compliance

Adhering to strict safety regulations is paramount for these professionals.

- Follow all safety protocols and procedures

- Wear appropriate safety gear and ensure personal safety

- Operate equipment within specified weight and speed limits

Interview Tips

Preparation is key for a successful interview. Here are some tips to help candidates ace their interview for a Longshore Equipment Operator position:

1. Research the Company

- Gather information about the company’s history, operations, and industry standing

- Learn about their safety record and commitment to employee well-being

2. Practice Your Skills

- Review the key job responsibilities and try to recall specific examples of your related experience

- Consider using the STAR method to structure your answers, highlighting the Situation, Task, Action, and Result

3. Highlight Your Safety Focus

- Emphasize your unwavering commitment to safety and adherence to regulations

- Provide examples of your proactive approach to risk identification and mitigation

4. Show Your Physical Fitness

- Be prepared to discuss your physical capabilities and ability to handle the demanding nature of the job

- Highlight any relevant training or certifications that demonstrate your fitness level

5. Demonstrate Your Teamwork Skills

- Emphasize your ability to work effectively in a team environment

- Provide examples of your communication and collaboration skills

6. Dress Professionally

- First impressions matter, so dress appropriately for the interview

- Consider wearing business casual attire or a uniform similar to what is worn on the job

7. Be Punctual

- Arrive for the interview on time to show your respect for the interviewer’s schedule

- Plan your route in advance to avoid any potential delays

8. Ask Questions

- At the end of the interview, prepare thoughtful questions to demonstrate your interest and engagement

- Ask about the company’s safety culture, opportunities for advancement, and training programs

9. Follow Up

- Send a thank-you note to the interviewer within 24 hours of the interview

- Reiterate your interest in the position and express your appreciation for their time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Longshore Equipment Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.