Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Longwall Shearer Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Longwall Shearer Operator so you can tailor your answers to impress potential employers.

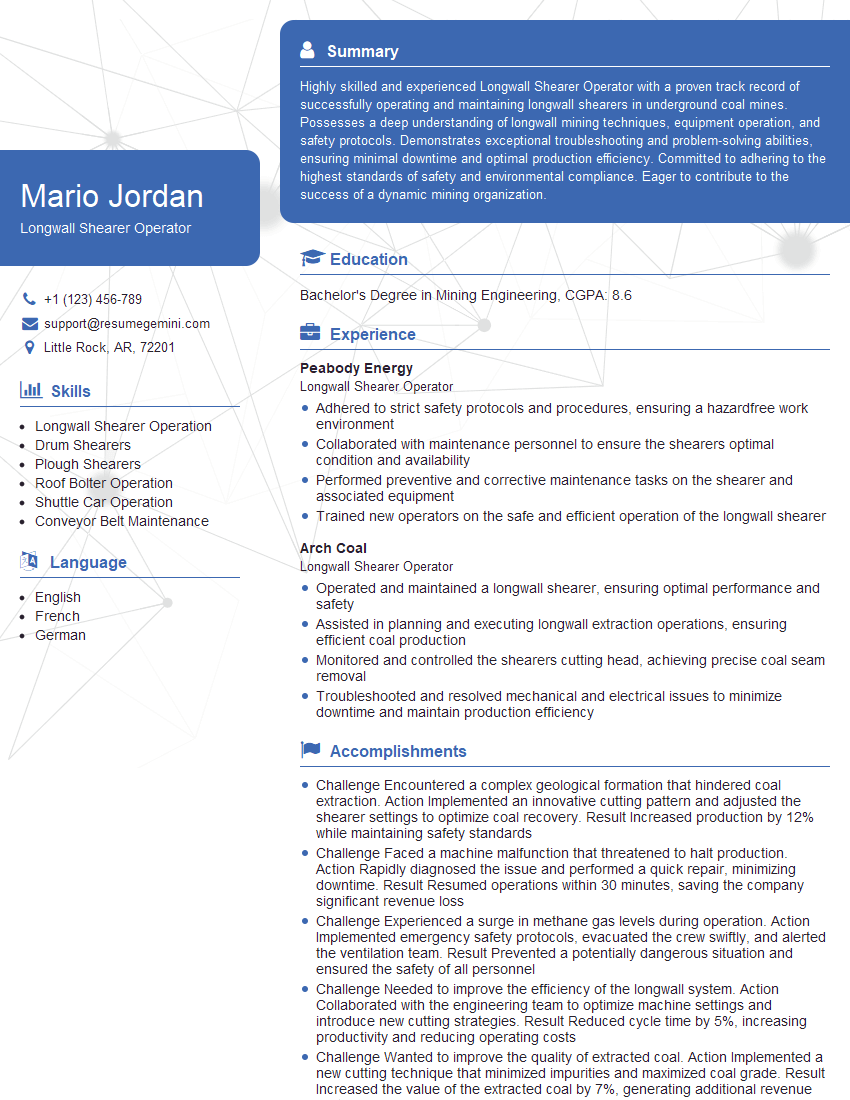

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Longwall Shearer Operator

1. How do you ensure the correct alignment of the shearer during extraction?

To ensure the correct alignment of the shearer during extraction, I follow these steps:

- Constantly monitor the shearer’s position using the guidance system.

- Make necessary adjustments to the steering controls to maintain the desired alignment.

- Regularly check the roof and floor conditions to identify any potential obstacles or changes in seam height.

- Communicate with the support crew to ensure proper roof support and face conditions.

2. Describe the types of cutting tools used in a longwall shearer and how you select the appropriate tool for different mining conditions.

Types of Cutting Tools:

- Drum Cutters: For soft to medium coal seams with minimal inclusions.

- Ranging Arm Cutters: For harder coal seams with more inclusions or when cutting in a curved path.

- Disc Cutters: For very hard or abrasive coal seams.

Tool Selection:

- Consider the coal seam hardness and abrasiveness.

- Evaluate the presence of inclusions or geological variations.

- Assess the cutting path and required maneuverability.

- Refer to manufacturer’s recommendations and consult with experienced colleagues.

3. How do you troubleshoot electrical faults on a longwall shearer?

To troubleshoot electrical faults on a longwall shearer, I follow a systematic approach:

- Identify the affected component or circuit using the shearer’s diagnostics.

- Check for loose connections, damaged wires, or blown fuses.

- Isolate the fault by disconnecting the problematic component.

- Perform electrical tests using a multimeter or other diagnostic tools.

- Replace faulty components or repair damaged wires as needed.

- Reassemble the system and verify functionality.

4. Explain the importance of maintaining proper tension in the shearer’s cutting chain.

Maintaining proper tension in the shearer’s cutting chain is crucial for:

- Optimal Cutting Performance: Correct tension ensures the chain meshes properly with the cutting tools, resulting in efficient coal extraction.

- Reduced Vibration: Excessive tension can cause excessive vibration, reducing cutting efficiency and damaging the shearer.

- Chain Safety: Inadequate tension can lead to chain derailment or breakage, posing safety hazards.

- Energy Efficiency: Proper tension reduces resistance during cutting, improving energy efficiency.

5. Describe the role of the dust suppression system on a longwall shearer and how you ensure its effectiveness.

The dust suppression system on a longwall shearer plays a critical role in:

- Worker Safety: Reducing airborne coal dust, minimizing respiratory hazards.

- Equipment Protection: Preventing dust accumulation on electrical components, reducing the risk of breakdowns.

- Visibility: Improving visibility for the operator, enhancing safety and productivity.

To ensure its effectiveness, I:

- Check the system’s nozzles for blockages or damage.

- Monitor water pressure and flow to ensure adequate coverage.

- Inspect the water tank for leaks or contaminants.

- Adjust nozzle positioning to optimize dust suppression.

6. How do you communicate with the support crew and other personnel during longwall mining operations?

Effective communication during longwall mining is crucial for safety and efficiency. I utilize various methods:

- Two-Way Radio: Primary means of communication with the support crew, surface personnel, and other shearer operators.

- Hand Signals: Used for immediate and non-verbal communication when radio communication is not feasible.

- Electronic Messaging: For non-urgent communication, such as requesting assistance or reporting observations.

- Face-to-Face Meetings: Regular meetings with the support crew to discuss upcoming operations, safety concerns, and any necessary adjustments.

7. Explain the factors that influence the production rate of a longwall shearer.

- Seam Conditions: Hardness, abrasiveness, and geological variations can impact cutting efficiency.

- Shearer Performance: Cutting tool selection, chain tension, and electrical system reliability.

- Support Crew Efficiency: Timely roof support installation and face preparation.

- Training and Experience: Skilled operators can optimize shearer performance.

- Maintenance and Repairs: Regular maintenance and prompt repairs minimize downtime.

8. Describe the safety protocols you follow while operating a longwall shearer.

Safety is paramount. I adhere to strict protocols, including:

- Pre-Shift Inspections: Thoroughly checking the shearer, controls, and surroundings for any potential hazards.

- Proper PPE: Wearing all necessary personal protective equipment, such as a hard hat, safety glasses, and gloves.

- Stay Alert: Maintaining constant awareness of the surroundings, roof conditions, and personnel movements.

- Communication: Keeping in regular contact with the support crew and other personnel to ensure coordination and avoid accidents.

- Emergency Procedures: Knowing and following emergency procedures for various situations, such as roof falls or electrical malfunctions.

9. How do you handle unexpected geological conditions while operating a longwall shearer?

Encountering unexpected geological conditions requires quick thinking and adaptability. I follow these steps:

- Assessment: Identify the nature and severity of the condition, such as faults, inclusions, or water pockets.

- Communication: Report the condition to the support crew and supervisors immediately.

- Adjustments: Modify cutting parameters, tool selection, or shearer position to navigate the condition safely.

- Safety First: Prioritize the safety of myself and the support crew, taking necessary precautions to avoid hazards.

- Documentation: Record the condition and any actions taken for future reference and analysis.

10. Explain how you prioritize tasks and manage your time effectively while operating a longwall shearer.

Prioritizing tasks and managing time are crucial. I follow these principles:

- Safety First: Always prioritize safety-related tasks, such as inspections and hazard identification.

- Production Targets: Focus on achieving production targets while maintaining quality and safety standards.

- Communication: Regularly communicate with the support crew and supervisors to coordinate tasks and resolve issues.

- Flexibility: Adapt to changing conditions and adjust priorities as needed, such as responding to unexpected geological events.

- Continuous Improvement: Seek opportunities to improve efficiency and optimize processes, reducing downtime and maximizing productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Longwall Shearer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Longwall Shearer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Longwall Shearer Operators are highly skilled professionals responsible for operating and maintaining longwall shearers, complex machinery used in underground coal mining.

1. Shearer Operation

Operate and control longwall shearers to extract coal from the coal seam.

- Monitor shearer performance and make necessary adjustments to maintain optimal production.

- Troubleshoot and resolve mechanical and electrical issues with the shearer.

2. Shearer Maintenance

Perform routine maintenance and repairs on longwall shearers to ensure safe and efficient operation.

- Inspect and replace worn or damaged components.

- Lubricate and adjust equipment to minimize downtime.

3. Safety and Compliance

Adhere to all safety regulations and procedures while operating and maintaining longwall shearers.

- Wear appropriate personal protective equipment (PPE) and follow safe work practices.

- Identify and mitigate potential hazards in the work area.

4. Communication and Teamwork

Effectively communicate with other team members, including shearer assistants, maintenance personnel, and supervisors.

- Provide updates on shearer performance and maintenance needs.

- Coordinate with other departments to ensure smooth and efficient operations.

Interview Tips

To ace the interview for a Longwall Shearer Operator position, follow these tips:

1. Research the Company and Industry

Gather information about the mining company, its operations, and the specific longwall operations where you will be working.

- Read the company website, industry news, and relevant articles.

- Network with professionals in the field.

2. Highlight Your Skills and Experience

Clearly articulate your skills and experience relevant to the job requirements.

- Emphasize your proficiency in operating and maintaining longwall shearers.

- Showcase your knowledge of mining safety regulations and best practices.

3. Prepare for Technical Questions

Anticipate and prepare for technical questions related to longwall shearer operation and maintenance.

- Study the shearer’s operating manual and maintenance procedures.

- Practice troubleshooting common mechanical and electrical issues.

4. Demonstrate Safety Consciousness

Consistently stress the importance of safety and your commitment to adhering to all safety protocols.

- Explain how you identify and mitigate hazards in the work area.

- Provide examples of your safety-first mindset in previous roles.

5. Showcase Your Teamwork Ability

Highlight your abilities to effectively communicate with and collaborate with team members.

- Share experiences where you successfully worked as part of a team to achieve common goals.

- Explain how you foster open communication and resolve conflicts constructively.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Longwall Shearer Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.